Eight tips to prepare your trucks for winter

Like it or not, winter is coming. You know the drill: falling temperatures, snow, and ice hitting large swaths of North America, presenting challenges for trucks and fleets. Now is the time to prepare. With harsh weather looming, this installment of the Bendix Tech Tips Series serves up eight pieces of advice for wheel-ends, air

Bendix talks safety system data at the HD Repair Forum

In addition to protecting your fleet and drivers from accidents, advanced driver assistance systems (ADAS) also gather quite a bit of data that can be useful to a fleet. Jim Barber, Bendix director of fleet sales and service, NA-West, addressed the topic in a recent talk at the Heavy Duty Repair Forum in September. “Our

Photo gallery: TMC 2021

For the first time since February 2020, a veritable lifetime ago, the American Trucking Associations’ Technology and Maintenance Council (TMC) held its usual meeting and exposition, this time in the fall rather than in the winter and held in Cleveland, Ohio—right in Fleet Equipment‘s backyard. With that being the case, the crew at Fleet Equipment

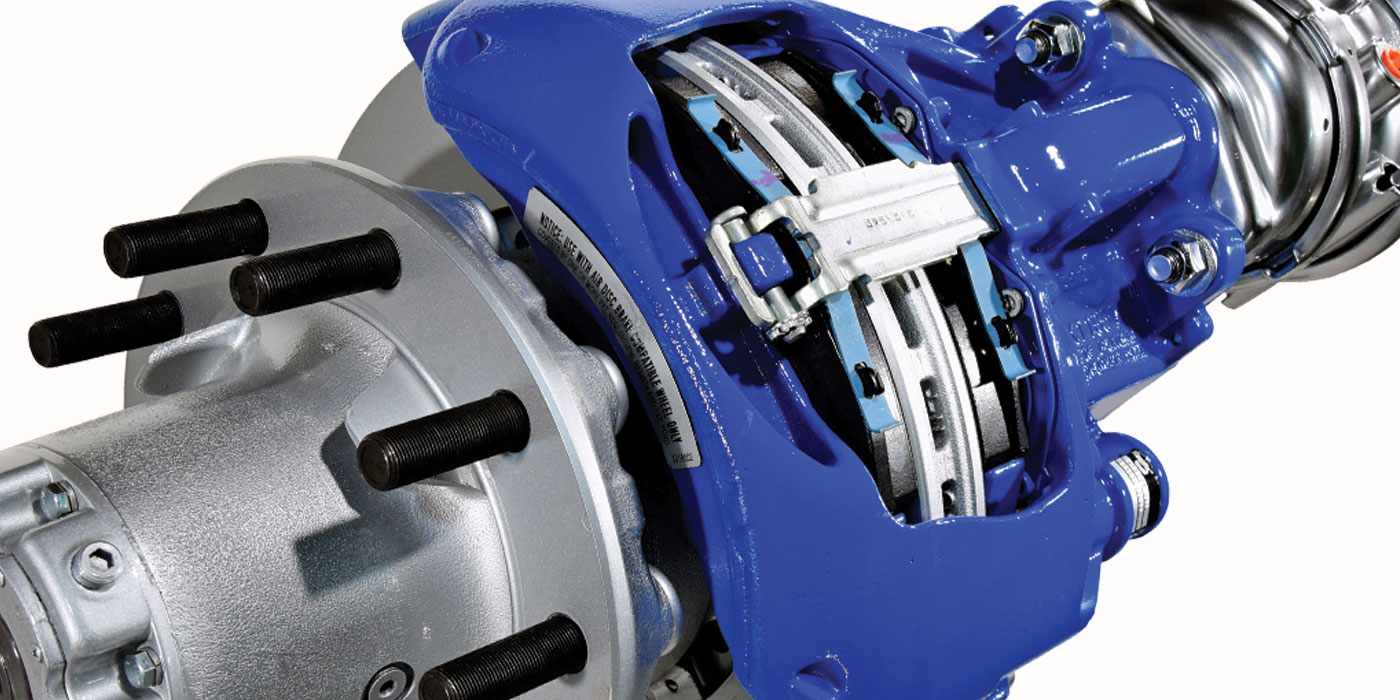

What fleets need to know about truck brake, wheel end service

While a comprehensive maintenance program is always essential for the performance of key heavy-duty truck brake and wheel end systems, it can be even more critical when fleets adopt new and different types of components and technologies. “Regulatory changes, such as those requiring copper-free brake pads, may influence maintenance intervals for brake components,” says Jeff

Today: Join a live conversation on ADAS and service with Bendix and Noregon

It’s important to stay up to date on ADAS and service processes. The importance of holistic diagnosis is greater than ever. Whenever a truck is in the shop, it should be scanned with a comprehensive diagnostic solution to help get ahead of issues before they become safety problems on the road. An upcoming Fleet Equipment

The ABCs of winter trucking prep: Controls

In the ongoing “ABCs of winter trucking prep” series of tech tips from Bendix, the “C” is for controls. “Driver assistance technologies, such as stability and collision mitigation systems, may be called upon more often in wintry road conditions, while tire pressure monitoring systems are valuable in keeping proper inflation during temperature swings,” said TJ

The ABCs of winter trucking prep: Brakes

In the ongoing “ABCs of winter trucking prep” series of tech tips from Bendix, the “B” is for brakes. “At the wheel ends, the onset of winter weather means paying extra attention to brake components,” said Mark Holley, director of marketing and customer solutions—wheel-end. “During pre-trip walk-arounds, drivers should look at the air brake chamber

Fleet profile: Newman Carriers is focused on dependability

For Newman Carriers, safety of equipment and well-trained drivers are among the keys to ongoing success.

Preventive maintenance truck tips for automatic slack adjusters

Time and miles: Both seem to roll by more quickly than we realize. Consider six months, 1,800 operating hours, or 50,000 miles – for many working trucks and truck drivers, those aren’t long intervals: But they’re key markers for a piece of basic wheel-end preventive maintenance that’s too often overlooked. This installment of the Bendix

Kenworth introduces new options for T270, T370 medium-duty conventional trucks

Kenworth is offering new options for its T270 and T370 medium-duty conventional trucks. The roll-back flatbed application is now an approved body type for use with the Kenworth AG210L single-axle rear suspension on the T270 and T370. The Kenworth AG210L is a 21,000-lb. rated highway, two-bag, rear air suspension that features a proven trailing arm

Upkeep and maintenance of steering gears

With the continued integration of more technologies into automated commercial vehicle safety systems, steering gear maintenance is an often neglected, yet key element in the effective operation of advanced driver assistance systems (ADAS). The most common steering gear location is on the steer axle’s left-side frame rail, although vehicles with large front axle ratings—such as

Using truck telematics to improve your fleet’s safety

From getting started to talking with drivers about the data.