Shop profile: Kriete Truck Center—Madison

It takes a team to keep trucks moving smoothly through a shop facility and back onto the road, notes Shelley Oldenburg, medium-duty service manager at Kriete Truck Center—Madison.

Why you should consider partnering with an independent heavy-duty service provider

Your fleet’s truck service bottom line depends on you. You’re on the shop floor with your techs, in the back office watching the P&Ls and ensuring that trucks are getting in and out of your facility as efficiently as possible. Yet in today’s world of high freight demand, there’s always more to do and that

Penske is turning its service centers into heavy-duty shops of the future

A bright yellow Volvo VNL sporting the signature two-tone blue lines running down its doors pulled into an open bay at Penske Truck Leasing in Brook Park, Ohio. A technician grabbed a headset attached to a device that clipped to his belt and started up Penske’s preventative maintenance protocol. “To start work, say, ‘Ready.’” The

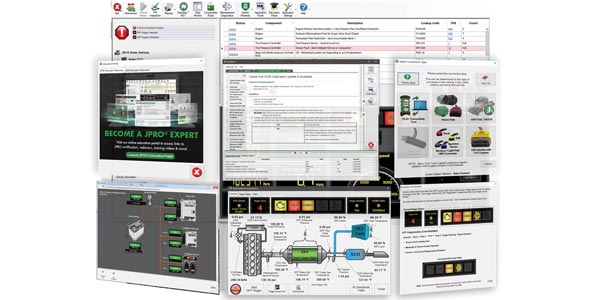

The impact of service technology on the technician

Like all things in the trucking world, technology is rapidly advancing new solutions. Change is constant, and who doesn’t love change? I can see you grimacing at the word, but there are big gains to be had if you embrace change and work through the transition pain points of a new process. This can be

Tracking truck tire inflation can pay dividends

According to the Technology & Maintenance Council of the American Trucking Association (ATA), a constant 20% underinflation in a commercial vehicle tire increases tread wear by 25% and reduces the tire lifetime by 30%. This results in significant increase in tire costs for a fleet. It also increases fuel costs. Underinflation of just 10 PSI

Capturing truck tire data during service: Why it matters and how you do it

Controlling tire cost is likely one of the biggest bullet points on your service to-do list. Despite daily checks and PM practices, unplanned tire service events still happen. Sometimes they can’t be avoided, but oftentimes they can be if you’re looking at the right data. It’s imperative that you are capturing the right tire during

Picking the right partner: OEM, Supplier channels

Not only is your parts selection important, but your choice of parts supplier also plays a huge role in your service success. OEMs and suppliers have been pumping big investments into their parts distribution network to make next day, or in some cases same-day, deliveries a reality. Daimler Trucks North America, for example, will open

Foreseeing your parts inventory future: Reading the data tea leaves to streamline your stock

Peer into the stock truck parts crystal ball where your historic service data swirls with tomorrow’s parts need driven by your drivers’ operational habits, parts suppliers’ distribution channels, and the once dreamed-of, now near-reality predictive maintenance algorithms. There are riches to be reaped if you can leverage the information already at your fingertips to shave

Good, better, best parts—finding what fits your needs

The array of aftermarket part options runs the quality gamut from “it’ll work” to “it’ll last.” To determine the right part fix for your job, Corneliu Bogdan, Eaton’s director of aftermarket product strategy, recommends looking a few key metrics. “The age of the vehicle and the expected retention period for the asset has to be taken

Revenge of the regen

“Regeneration.” The word alone is enough to send chills down a fleet service manager’s spine. Although the reliability of aftertreatment systems has improved over the years, it’s still a top service pain point for fleets polled by Fleet Service Technology. One of the latest headaches is the abuse of the regen inhibit button. With a single

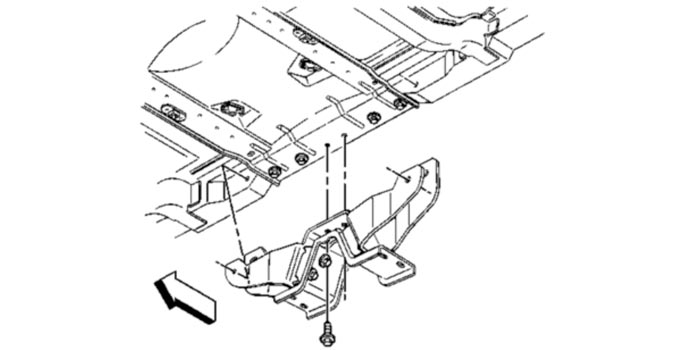

That tingling sensation: How driver discomfort can reveal areas of the truck in need of maintenance

The driver climbs out of the cab, rubbing a leg when dropping the truck off for regular service. “How’s your day going?” you ask. “Great!” the driver responds, “Except for my leg going to sleep.” “Yeah, I hate it when that happens,” you respond. The conversation goes on as you and the driver discuss the

Predictive maintenance is coming

“Machine learning.” It’s a phrase that’s cropping up more and more in conversations about data-driven solutions. In the heavy-duty service world, one of the ways it’s being employed is through predictive maintenance algorithms, complex strings of code that crunch your service data, analyze it and then give you recommendations based on probability models. Make no