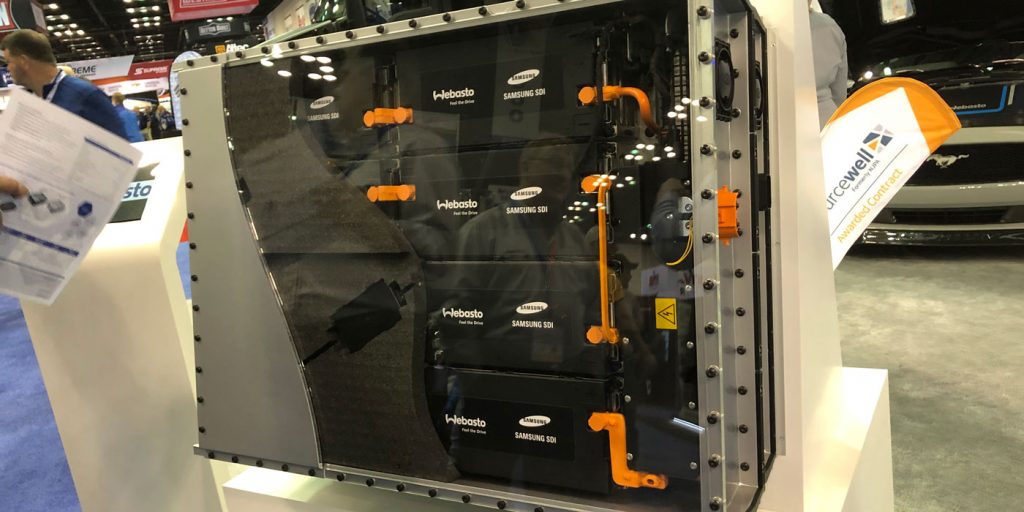

Webasto displayed its new modular CV standard battery system at this year’s NTEA Work Truck Show in Indianapolis. With 400V and 800V versions available, each battery pack has 35 kWh of energy, and because up to 10 packs can be used for a combined 350 kW, the system is designed for scalability and configuration flexibility.

The company turned a few heads after first exhibiting elements of the system in Ford Motor Co.’s booth at the 2019 SEMA Show in Las Vegas. The company walked away with Ford’s 2019 Best of Show Stand Award for Outstanding Achievement in Design for Mustang Lithium (pictured below), a one-off battery-electric prototype with 1,000 ft-lbs. of torque and over 900 horsepower.

Fleet Equipment caught up with Josh Lupu, Webasto’s director of marketing, at the Work Truck Show for an explanation on how the CV Standard Battery system will work to meet the requirements of commercial vehicle manufacturers.

Check out all of our coverage of this year’s Work Truck Show here.

Fleet Equipment: How did Webasto’s partnership with Ford begin?

Josh Lupu: We’ve been designing products for Ford vehicles for many years. We supply Ford currently with some product—on the Mustang, specifically, the convertible roof. For this [Mustang Lithium] vehicle, it was part of their SEMA program. We wanted to bring a vehicle that demonstrated Webasto’s capabilities in battery, thermal management and charging, but also let the general public know that electric vehicles can be fun to drive. It can be exciting. There is a perception that electric vehicles are boring and there’s no fun in them. We wanted to bring a performance vehicle that’s an extreme example of electric performance: 1,000 ft./lbs. of torque in a muscle car. We wanted to show that Webasto can bring passion, quality and innovation to electric vehicles. We did that with the Mustang, and we’re doing the same with our commercial vehicle battery solution as well. Winning the award at SEMA from Ford really proved that we are on the right path for electrification.

FE: You describe this system as a “plug-and-play system.” What does that mean?

JL: We wanted to keep it less than 700 mm in width, to be able to fit between the frame rails. And then, from the energy content standpoint, we found a lot of light vehicles needing 30 to 50 kWh. So, we had the building block of 35 to start with. We thought if we made a building block of 35, it’s good for light commercial. Then, go to medium-duty by just adding two, three, four or five packs. And then, heavy-duty can go up to 10 packs.

FE: Why is there a ceiling of 10 packs?

JL: It’s the number of inputs into our vehicle interface box. It has five inputs. You can run five packs in parallel configuration, or 10 packs in a series, to achieve 800 volts. It’ll hold 400- and 800-volt systems. If we have a manufacturer that needs more than 10 packs or more than 350 kWh, we just add a second to VIB. Then they can continue the scale.

FE: In developing this product, how important was it for fleets to have the plug-and-play capability?

JL: That was one of the main driving important things, the other being the dimensional form factor. We said, “Okay, how can we help influence EV adoption rates? How can we contribute to that?” It is very, very costly, to electrify a platform. The level of R&D and financial investment can make it cost prohibitive. And then, of course, that has to be passed to the end user.

Our way of contributing to that was to offer a solution that helps the manufacturer to make a common battery system where they don’t need a new system for every single platform or every single vehicle. Being plug and play makes it easier and more cost-effective. That was one of the biggest driving factors in our design process.

FE: What do you think is the biggest advantage to the customer?

JL: I would say it gives them a battery system that is perfectly matched for the vehicle they’re driving. They don’t have to compromise. They don’t have to live with an inadequate or undersized system, and they don’t have an overkill system where they have more battery than they need. So, because it’s scalable and modular, it allows the manufacturer to pick the exact energy capacity that they need, which then helps the end user for his application. And, of course, because it is DC fast charge ready and Level 2 AC charge ready, and some fleets prefer one or the other, it allows for the fast charge if you need it or a slower Level 2 AC charge.

FE: In developing this, did you have any specific fleet or application in mind that you thought might particularly benefit from this kind of system?

JL: Yeah. It was really light commercial, medium-duty and some heavy-duty on-road applications. So, last-mile delivery, medium-duty vocational and regional haul.

We looked at the footprint of chassis cabs, Euro-style vans, work vans and shuttle/transit bus. The contributing factor was the distance of the frame rails. So, we designed it so that the energy capacity and dimensional form factor provides a solid building block, if you fit it between the frame rails. We were really envisioning really Class 2 through 8.

FE: How important is the ability to provide both 400V and 800V systems?

JL: Having 400V and 800V is important. There are some manufacturers that do both currently, some only do 400V. There are some that have 400V products on the market today, or at least in development, but their future product roadmap shows 800V. This allows them to use the same system, the same package. They can run the system in parallel and it’s 400V. If they run it in series, it’s 800V. It allows them to reduce their time to market and their costs too. Going back to the end user … it allows that manufacturer to give them a 400V solution or an 800V solution and, basically, keep up with the evolving technology.