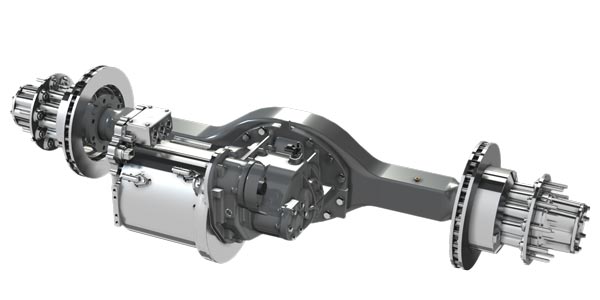

There are three options currently being used for motor placement in an electric powertrain: centralized direct drive solutions, centralized motor with a gearbox or deep reduction axle gearing, or an e-axle in which the motor is placed directly onto the axle itself.

According to Steve Slesinski, director of global product planning for Dana, the latter option is the most advantageous long-term. “By integrating the power source into the axle you have a far shorter path to deliver torque to the wheels which eliminates parasitic losses and provides improved responsiveness,” he explained. “This also eliminates the entire powertrain in front of the rear axle which provides package space and weight reduction for high voltage battery storage. The fewest connections and shortest length of cables will provide a more efficient solution. e-Axle solutions require additional chassis architectural changes to the vehicle to handle the redistribution of weight and driving performance; however, Dana feels this will be the future of electrified vehicles.”

“With the present technology that is on the market today, the most effective place to put the motor is directly in the axle,” agreed Thomas Healy, chief executive officer of Hyliion, makers of a hybrid electric system called the 6X4HE. “And for the highest efficiency, the motor will spin in parallel with the wheels as opposed to perpendicular. This configuration eliminates much of the gearing that produces drag and efficiency losses on the vehicle.”

When developing their electric FL and FE trucks for Europe, Volvo went with an electrical motor and a two-speed transmission with a prop shaft driving the rear axle. The electric motor on the FE is rated for 627 lbs./ft. of torque, and the rear axle gets 20,652 lbs./ft. of torque. The FL’s electric motor, meanwhile, is rated for 313 lbs./ft. of torque, and its rear axle gets 11,801 lbs./ft. of torque.