There’s big money to be saved by keeping tires in service until their full treadlife is realized. Over the years, maintenance managers have had diverse thoughts on the most cost effective way to accomplish this.

Some included using deeper tread depth remaining guidelines when replacing drive tires in fall vs. spring and summer to assure more actual winter traction. Many tires are removed early because their drive, tag or trail axle dual mates have been damaged, run flat, or developed irregular wear. Steer tires are commonly rotated to trailer positions for runout with one third or more original tread depth remaining.

Based on current industry trends and tire costs, fleet tire pull guidelines and maintenance practices should be reviewed. Practices established in the days of lower cost, older technology tires and cheaper shop rates may be costing fleets dearly.

Tire designs that are more fuel-efficient and resistant to irregular wear, along with increasing servicing costs for tire changes (not associated with PMs or other routinely scheduled maintenance) can lead to fleets losing operating savings, which can accrue in the later stages of tire life.

For example, most tire manufacturers observe slower wear rates with diminishing tread depth. Increased miles per 32nd of tread loss in the order of 25% or more are common when comparing the same tires at 80% wear vs. nearly new. Tires delivering 12,000 mi./32nd in their early life may commonly deliver 15,000 or more miles/32nd as they approach required take-off depths. This is generally valid for rib and lug tread designs on power unit steer and drive axles.

Another advantage is that rolling resistance (thereby fuel efficiency) improves as tires wear. This improve-

ment is significant. Most tire engineers agree there often is more difference in the rolling resistance of the same tire new vs. approaching wear-out than exists between major brands of comparable tread types.

Documented testing has shown this improvement in rolling resistance from new to 80% worn to be approximately 6.5%. This can easily translate to an overall truck fuel economy advantage of 1.5%—not a bad return for good tire maintenance and updating some tire program guidelines.

Of course, all operators must comply with federal, state and local regulations for minimum tread depth standards, which normally require steer axle tires to have at least 4/32nds of tread depth and all other wheel positions to have at least 2/32nds. Tires with irregular wear are often considered “worn out” when there is significant tread depth remaining. There are three ways to avoid irregular wear:

First, always maintain proper inflation for the loads/service conditions. This may mean having several different inflation specs for dedicated vehicles based on their unique configuration and service conditions.

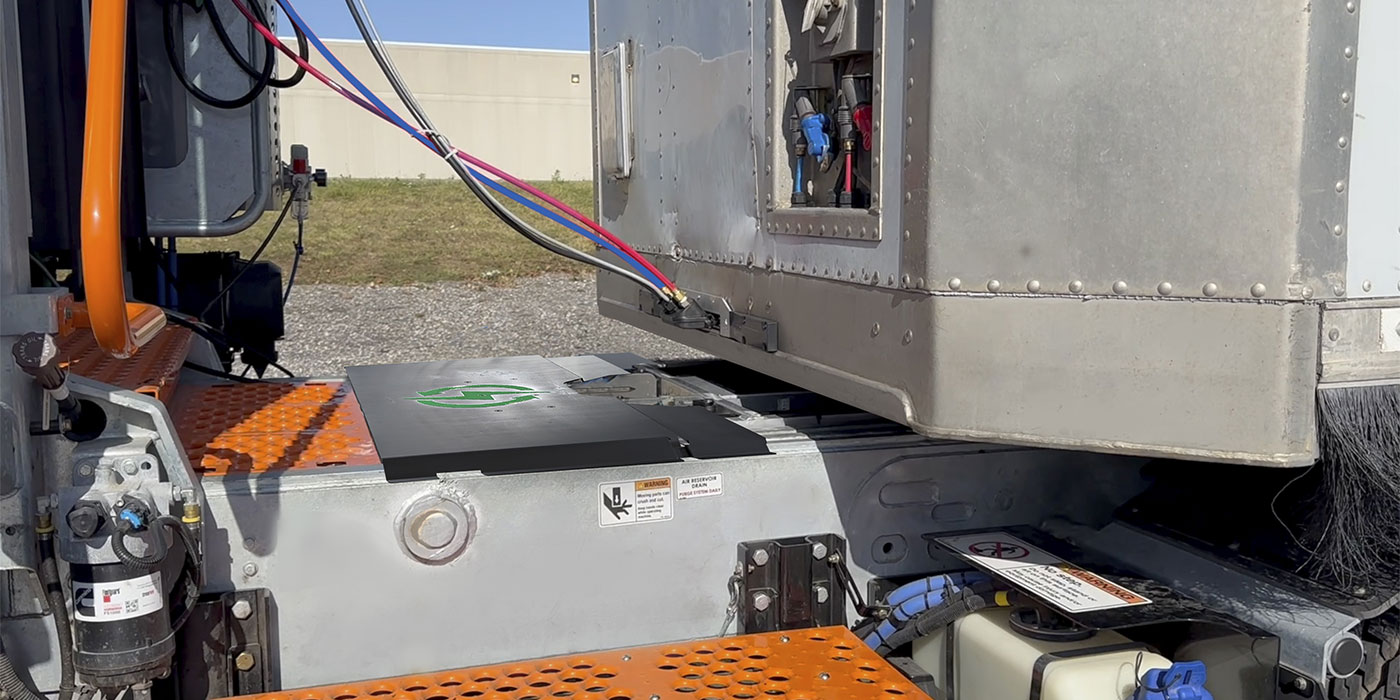

This is especially easy to accomplish on trailers equipped with automatic tire inflation systems (ATIS). The use of valve extensions that have a closed annular area keep dirt, road clearing chemicals and other outside debris from entering the valve sealing area. Filtered valve cores that keep debris from inside the tire at bay also are highly recommended.

Second, maintain truck alignment within close tolerances. Steer axle toe should be kept to a minimum toe-in, if possible within 1/16 of an inch or less. Chassis thrust angle, controlled primarily by drive axle alignment, is now more important to tire wear than before. This is primarily due to the high torque levels now common with modern diesels, along with softer riding suspension systems. High quality torque arm and other suspension bushings are necessary to minimize the difference between at-rest and dynamic (under torque) drive axle alignment. In extreme cases, it may be desirable to preset a small amount of misalignment to offset a shift, although this is generally not recommended and vehicle manufacturers should be consulted. Remember that symptoms of misaligned drive axles show up first as irregular wear on steer tires.

Third, balance all wheel positions for optimum tire wear. Since all tires lose a significant amount of weight during normal wear (drive tires typically lose 30 lbs.), it may be necessary to periodically re-balance or use an adaptive type of internal balancing media to accomplish this.

These are simple, effective steps to avoid premature tire removals and get late tire life cost savings. Fleet financial people will also appreciate a delay in buying new tires.