Among the goals that Mark Roberts, president of CTI Logistics Inc., has for his family-owned company’s fleet are two that he says are definitely keys to success. “Hanging on to good drivers and generating the best possible fuel consumption are ongoing challenges,” he states. “In today’s economic environment, and with rates where they are, it’s especially trying to compete cost efficiently against our competitors, including some of the country’s largest carriers.”

Headquartered in Columbus, Ind., CTI Logistics and Central Trucking Inc. (CTI), a refrigerated carrier, are run by Mark Roberts and his brother Keith Roberts II. Founded in 1974 by their father Keith K. Roberts, CTI services a variety of shippers from points in the east and Midwest to the west coast. A typical trip for the fleet consists of taking dry commodities west and hauling fruits and vegetables from California, Arizona and Nevada on the return trip.

“Recruiting and training new drivers is a large expense,” Roberts says, “so retaining good drivers can effectively reduce some of our costs. What we’ve put in place to help attract and retain drivers is a Pony Express-style operation. Along with team service with third day delivery to and from the west coast, we have a slip seat setup through four facilities located about nine hours apart along the 1-40 corridor in Columbus, and at satellite terminals in Springfield, Mo., Amarillo, Texas, and Kingman, Arizona.”

The four terminal relay system with equipment domiciled at each facility, Roberts explains, allows the fleet’s 380 drivers to run nine hours, take a 10-hour rest break and return home on another nine hour trip. “Driver culture was changing,” he says, “and we saw that it was getting harder to find drivers who wanted to be on the road for weeks. This set up means no one has to be out more than two days in a row. It also eliminates hours-of-service issues, improves customer service, enhances safety by putting a fresh driver behind the wheel all the time and has brought our turnover rate down.”

Retention tool

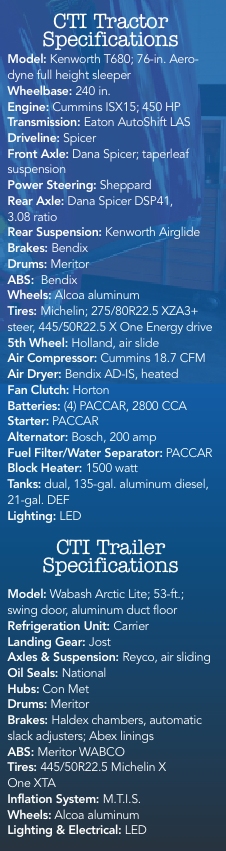

Roberts also sees late model equipment as an effective driver retention tool. The CTI fleet consists of 220 Kenworth tractors, including T660 units and 20 new T680s, and 255 Wabash National refrigerated trailers with Carrier refrigeration units. “The slip seat operation puts about 200,000 miles per year on each tractor,” he says. “Our tractors and trailers are routinely traded after two or three years of service, so we never have any vehicles with 500,000 miles on them. Not only does that keep drivers happier, it also means that our 75 technicians at shops in Columbus, Springfield and Kingman can focus on preventive maintenance and minor repairs, eliminating hassles for drivers and keeping costs in check.”

Roberts also sees late model equipment as an effective driver retention tool. The CTI fleet consists of 220 Kenworth tractors, including T660 units and 20 new T680s, and 255 Wabash National refrigerated trailers with Carrier refrigeration units. “The slip seat operation puts about 200,000 miles per year on each tractor,” he says. “Our tractors and trailers are routinely traded after two or three years of service, so we never have any vehicles with 500,000 miles on them. Not only does that keep drivers happier, it also means that our 75 technicians at shops in Columbus, Springfield and Kingman can focus on preventive maintenance and minor repairs, eliminating hassles for drivers and keeping costs in check.”

CTI has also made significant gains in improving fuel efficiency. “Five years ago, we were averaging 5.3 MPG,” Roberts states. “Today, our fleet average is in the high 7 MPG range and some units are getting more than 8 MPG. We attribute that to doing our homework about vehicles and fuel saving specs, including talking to other fleets to learn from their experiences.”

Along with switching from long nose conventionals to more fuel efficient tractor models, Robert relates that CTI changed its specs from 485-HP Cummins engines to 450-HP models with the manufacturer’s Smart Torque solution, a system that minimizes the number of downshifts required to maintain road speed. Additionally, the fleet lowered maximum road speed on its tractors to 62 MPH by the pedal and 65 MPH when cruise control is in use.

Side by side

“In 2009, we did a side-by-side comparison using 12 trucks with manual transmissions and 12 with Eaton UltraShift PLUS LAS automated gearboxes,” Roberts relates. “The result was a one-half mile per gallon fuel efficiency gain, which is very significant when you take into account the number of miles we cover over the course of a year. We were one of the original fleets to try UltraShift PLUS transmissions and we’ve stayed with them ever since. As of our last truck order, the entire fleet is now equipped with the UltraShift PLUS.“Eaton UltraShift PLUS Linehaul Active Shifting (LAS) automated transmissions are built on the manufacturer’s Fuller 10-speed manual transmission platform. The automated version is available in overdrive and direct-drive versions and can be paired with engines rated from 1,450 to 1,850 lb./ft. of torque.

The UltraShift PLUS transmission uses an electronic clutch actuator for faster and smoother shifts that save fuel, Roberts notes, and at idle the clutch is fully engaged to give drivers more control in tight spaces. The transmissions also feature automatic, manual and low modes, and a Hill Start Aid, which prevents roll-back and roll-forward while launching on grades.

Just as significant to Roberts is the way CTI drivers have taken to the automated transmissions. “There was some initial reluctance, especially from veteran operators,” he says, “but that disappeared as we continued to add them to the fleet. Once they drove with the automated gearbox, most of our drivers liked the convenience of a two-pedal transmission that eliminates the need for shifting and operating a clutch. What they realized was that they were much less worn out at the end of the day.”

Fuel saving specs

Other fuel saving specs at CTI include the Idle Free Systems electric APU for HVAC needs and electricity to run hotel loads, Michelin X One Energy D wide base single drive and trailer tires on Alcoa aluminum wheels and all tractors and trailers in the fleet now have Deflecktor aerodynamic fabric wheel covers. Additionally, the fleet’s Wabash National reefers are all equipped with the OEM’s DuraPlate AeroSkirt trailer side skirts and ATDynamics TrailerTails rear drag aerodynamic technology.

“Whether we’re running east, west, north or south, generating the best possible fuel efficiency and hanging on to good drivers are important keys to our profitability,” Roberts says. “Buying equipment built to our specifications maximizes fuel economy and helps retain drivers so we can service shippers more effectively and ensure that we remain profitable.”