Let’s take a step back from the focus on efficiency and talk about application. Sure, getting the most out of your truck is important, but if you aren’t putting just as much consideration into the impact your application has on your equipment, then you’re potentially setting yourself up for maintenance issues that could cost more than you’re efficiency is saving. Fleet Equipment tapped our panel of wheel end and wheel experts to talk about the role application plays in equipment selection and the potential pitfalls of improper spec’ing.

1. There is always risk in generalizing

When you consider the variability across on-highway applications—long haul fleets typically average over 100,000 miles per year and place a premium on maximum uptime, while regional haul fleets generally keep their equipment longer because it is exposed to lower annual mileage—it’s clear that there is no one-size-fits-all approach to specifying wheel ends and wheels. That said, more important than miles traveled is what you are hauling and the road conditions rolling down.

“For instance, premium bearings can benefit you if you have higher axle loads, in cases with extreme wheel offsets, or service conditions that include a lot of cornering; you can spec these if they are not standard,” explained Mark Wagner, vice president of engineering, wheel ends, Consolidated Metco Inc. (ConMet). “Mountainous regions, for example, can put a very heavy demand on brakes, so choosing the right drum or hub/rotor can have an effect on brake life and performance.”

Wagner explained that in today’s market, most trucks come standard with hubs that include some type of pre-adjusted bearing arrangement. (If they don’t, you should request them.) These systems have been on the road for more than 20 years and are well proven today. Many long-haul fleets have stated that virtually all of their bearing problems have gone away with these systems, according to Wagner. In addition, these packages are sold with premium seals pre-installed and often with premium bearings as well. These parts have been validated by both the wheel-end supplier and the OEM.

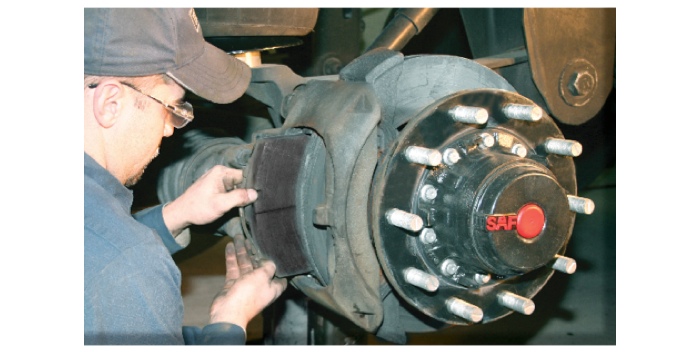

Additionally, most axle manufacturers are utilizing high-quality seals and bearings, which are typically the main concern when selecting long versus regional haul wheel ends would be proper brake lining to suit the vocation. “Higher grade lining that will withstand the greatly increased amount of stops encountered with regional trucking should be considered,” said Dennis Osiecki, SKF national accounts sales manager. “The SKF Plus XL Scotseal, for example, is designed to work in both wheel end environments.”

“Most [long haul] fleets look for long life wheel end packages that perform well in all-weather conditions and require minimum maintenance,” said Mark Holley, Stemco segment business leader. “The transition to outboard brakes has helped fleets gain extended wheel end life while being able to perform multiple brake jobs without replacing seals and bearings. I recommend a long life OEM wheel end warranty [three years for tractors and five years for trailers], as well as an extended warranty in the aftermarket [three years].”

Many regional haul applications involve driving or backing up into flooded areas or loading docks, Holley explained. That’s why it’s also important to ask your service provider if your wheel end has contamination resistant technology, which helps prevent water ingress and allows the wheel end to vent.

“Environmental conditions, lack of service facilities, and scheduled inspections often impact the wheel end component selection,” explained Bill Hicks, product planning, trailer suspension systems, SAF-Holland Inc. “Most wheel end providers do de-rate their warranty coverage by application in some form.”

Let’s not forget duty-cycles: “When one attempts to optimize a wheel end for a specific application or duty-cycle, they should take the entire system into consideration,” said Adam Wiechmann, president of Webb Wheel products, specialty truck OEM. “This includes items such as vehicle type, tires, wheels and linings. Minimizing the total cost of ownership is always the goal, and we do our best to help customers decide what product selection makes the most sense for them.”

(Click “Next Page” to continue reading.)