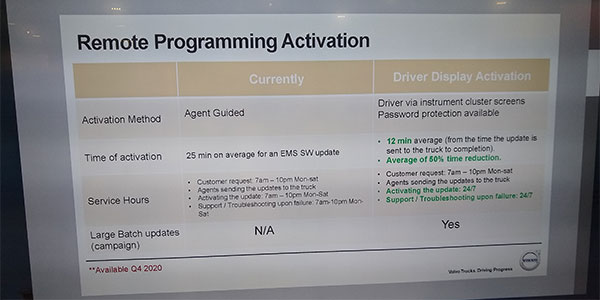

When Volvo Trucks North America introduces a new product, be it rolling iron or streaming data, they like to hold their customers’ hands to ensure there’s a degree of comfort and trust in the new product or service. So when Volvo Trucks began offering over-the-air updates on its engines in 2017, the execution of those updates was led by its 24/7 Uptime Center working with fleet managers, drivers and technicians to get engines updated.

“We have been very deliberate in collaboration with our customers regarding connectivity solutions,” stressed Conal Deedy, director of connected vehicle services for Volvo Trucks North America. “From the beginning, we knew this was something as new for our customers as it was for us. Having that direct contact with the person in the truck as we performed thousands of updates has given Volvo Trucks the confidence to take the next step.”

That next step was the announcement of Driver Display Activation, which allows drivers to update software and parameters at any time, from anywhere they have cellular service. Remote Programming Driver Display Activation will be available in Q4 of 2020. After the fleet manager has given permission for the updates to be pushed to the trucks, the driver can make the updates at their convenience, a detail Ash Makki was quick to point out when I caught up with him in the Volvo Trucks booth at the TMC Technology & Annual Meeting and Transportation Technology Exhibition.

Makki took me on a digital deep dive of how the new service works, detailed the decision-making role that fleet managers play and how the new service aims to speed up OTA updates even further.

FE: So let’s dive into the new stuff—Driver Display Activation.

Makki: [Laughs] I like talking to the people that work with this a lot because we just dive right in.

Currently, we have the agent-guided updates, meaning the Volvo Uptime agent has to be involved. With Driver Display Activation, it starts as a software update for the Volvo powertrain. First, we will let that decision-maker know via our ASIST platform or through email, saying, “We have a software update available to your unit. We’re going to push it to the truck.” So the decision maker, the fleet manager, is still involved in the whole process. In the case of parameters updates he or she is the one requesting the update from us.

FE: Okay, so how does this impact the overall OTA process?

Makki: So it’s an average of a 50% time reduction to the overall process, between taking out the agent conversation to optimizing the download speeds within the vehicle.

FE: How much time is saved?

Makki: With the agent-guided process, the longest time it takes is for one of our engine updates, which is about a 25- to 30-minute update. We reduced that to 12 minutes, and we stand behind that any day. We timed it. And that’s our longest update. The other updates are much faster.

FE: So let’s say the fleet manager has requested the update from Volvo, what happens then?

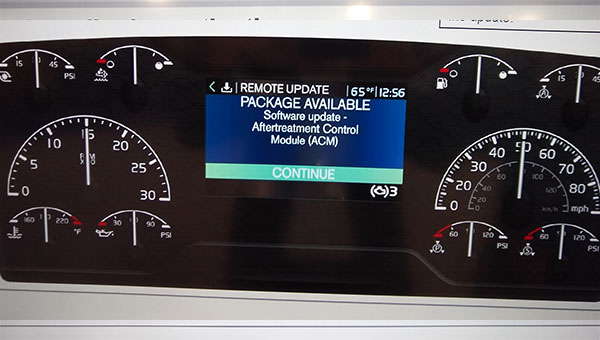

Makki: Whether it’s a software update or a parameter update, a notification shows up on the driver display as soon as the truck is started.

FE: So if it’s an engine update, it’s just a maximum 12-minute update before the truck can hit the road.

Makki: Right, and if it’s a parameter update—if the fleet manager wanted to update the road speed limit for example—that is, literally, about less than a minute and a half to complete.

FE: What about the option to update later like we see here?

Makki: If a driver chooses to update later, the update icon will remain on the driver display and it will prompt the driver to update every time he or she starts the truck. Our Uptime Agents are still monitoring the process. They let the decision maker know if the update was not completed or in case there was any kind of error. Communication is done through an ASIST platform notification or email—however the decision maker said he or she wanted to be notified.

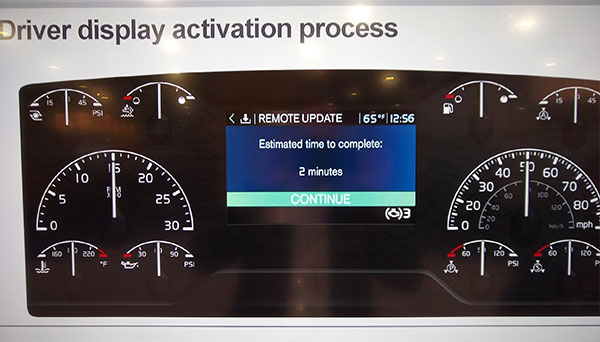

FE: Okay, so let’s assume that we want to update. What happens after the driver sees the notification?

Makki: The display will show you what kind of update it will be. So in this example, this is an aftertreatment system update. It will then tell the driver how long the update will take.

Now, here comes the flexibility. The decision-maker could decide that they want the update process to be password protected. When the driver gets to this level in the process it will prompt him or her for the password. The driver puts the password in, and we check that it matches the password we have at the fleet’s profile in the Uptime Center.

On top of that, we will make another option available. We’ve had customers say they don’t want the driver to see any notifications and they’ll take care of the update when it’s back in their service bays.

So continuing with the update, we come another chance to accept and continue or not. They could abort the activation if they want to, but after this we continue with the update. Going forward, we check for the right process parameters: The truck is off, key is in the on position, parking brake is pulled, cellular connection is good, the truck is parked on a flat surface—that’s mostly required for transmission or driveline updates because we want to make sure the hardware connections there are flush. And then we tell the driver not to touch the truck. We don’t want them turning it off during the update. Just don’t touch it.

They’ll see a percentage bar during the update and then we alert them that the update was successful, complete and them prompt them to turn the key off for 20 seconds, then start the truck and they’re done.

FE: Very cool. But it seems that with great efficiency comes great communication responsibility on the fleet manager’s side. They have to communicate internally more.

Makki: Yes, but we’re still developing the level of notification and visibility into the process. The technology is ready to go as today and is in the pilot phase. We’re gathering feedback on all of the settings, notifications—everything involved with this. The password feature is a great example of this. That was something that was requested that we build in. We’re going to be testing for the next two months. The pilot is going to let us know exactly what tweaks we need to do, which options are more acceptable before our full launch in the fourth quarter of this year.