Navistar rolled out the red carpet to cut the Navistar-orange ribbon, announcing the opening of the truck manufacturer’s San Antonio Manufacturing Plant–a more than $250 million investment that broke ground in June 2020 on a nearly 1-million square-foot plant has the capacity to produce Class 6-8 vehicles. I had the chance to walk the line and take a look behind the manufacturing scenes. Take this pictorial tour of the new facility.

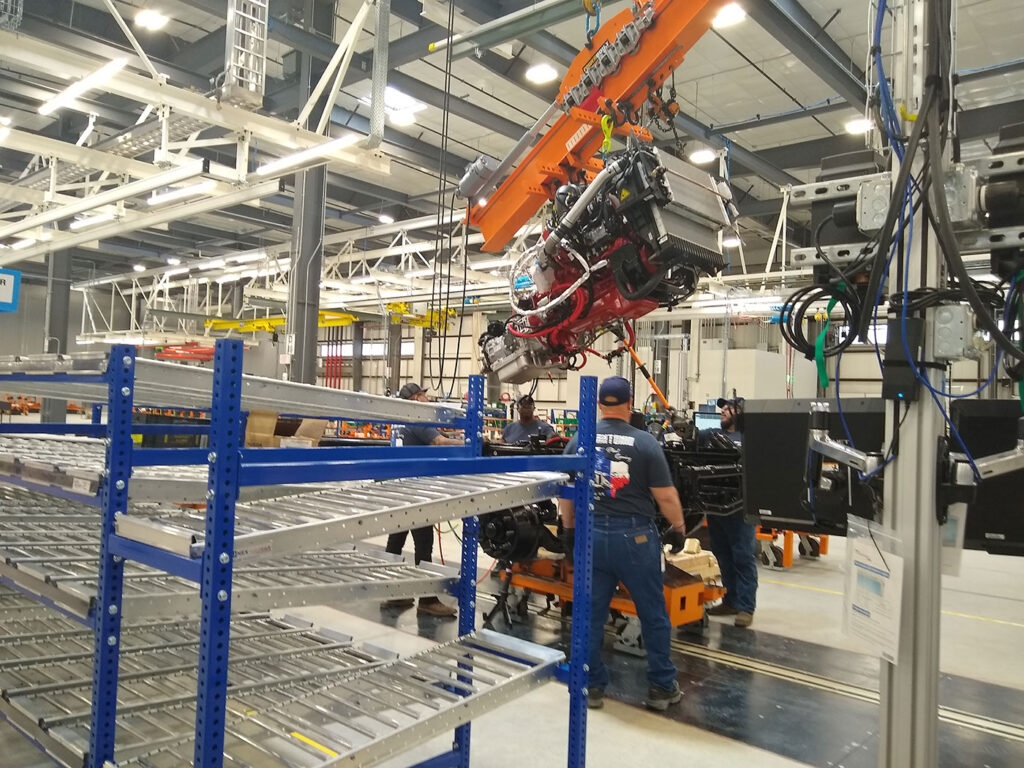

The facility includes a body shop, paint shop, general assembly shop and logistics center equipped to produce Class 6-8 vehicles, including electric vehicle models. With the plant officially open, Navistar aims to ramp up to building 52 trucks a day within the Q2/Q3 timeframe, running a single shift on 8-minute build cycles.

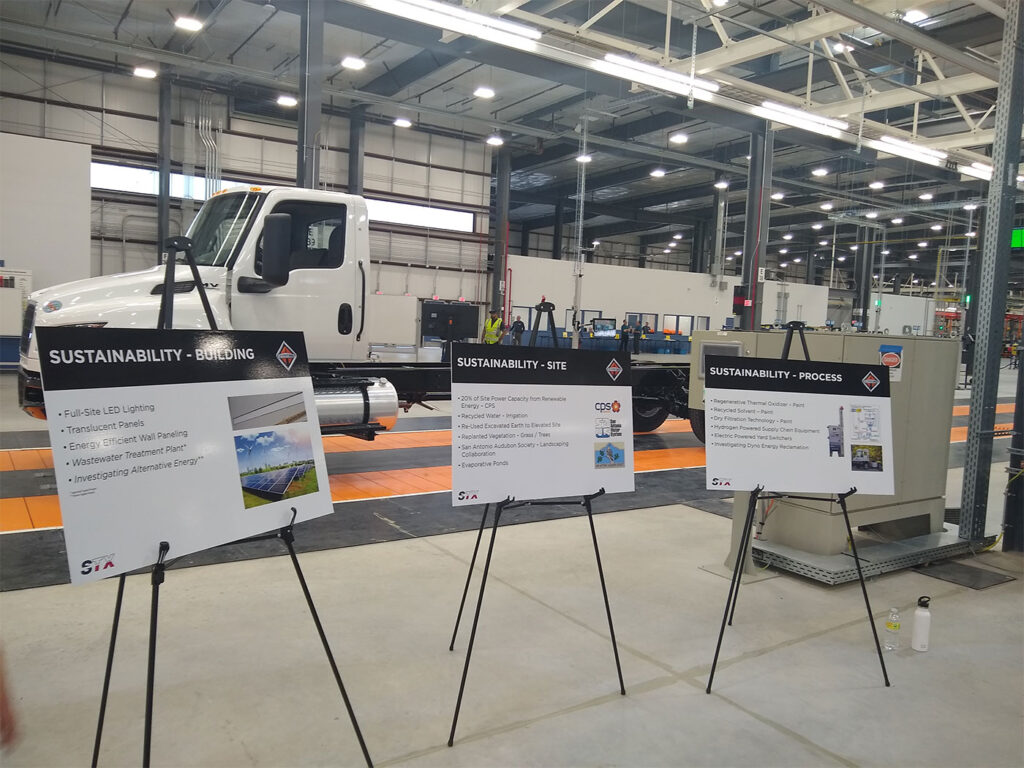

The plant is a sustainable baseline facility in site, building and process practices, to serve as a benchmark for Navistar’s manufacturing network.

The San Antonio Manufacturing Plant was constructed with efficient energy use goals in mind. As part of the U.S. Department of Energy’s (DOE) Better Buildings, Better Plants Program, Navistar is committed to reducing energy intensity in San Antonio and other U.S. plants by 20% by 2030.

Watch a chassis flip

When the chassis start down the line, they’re upside down. Then they’re flipped right side up to run down production line, and it’s always cool to watch:

LEDs illuminate the plant, using 75% less power than conventional lighting, and translucent panels allow natural light to brighten the indoor space as a supplement to the lighting system. The building also includes energy efficient wall paneling to better regulate indoor temperatures.

Industry 4.0 principles have been incorporated to connect digital and physical technologies, allowing the plant to be more connected and easily make data-driven decisions. Operating with a data-driven approach helps to focus on sustainability goals and metrics in addition to supporting a leaner manufacturing output, according to the manufacturer.

In the future, Navistar plans to begin operations at the Advanced Technology Center (ATC) on-site, which accelerates implementation of emerging technologies and Industry 4.0 technologies within the commercial trucking space. The ATC is focused on product development, testing and validation efforts supporting the company’s strategy, and will be a key location for future research and development footprint with a focus on zero-emission components, software and autonomous technologies.

The facility is currently capable of manufacturing EVs like the International eMV pictured above, and an expansion to increase EV manufacturing capabilities is already in the works.

The new manufacturing plant will bring approximately 600 jobs to the San Antonio area.