I’m ready to go out on a limb and say that conventional truck tire pressure checks, especially with that old faithful “calibrated to the shop master gauge” measuring tool may soon become a thing of the past. That may not be such a bad thing.

Several aspects of the traditional tire pressure checking have always bothered me. First, it is rarely done frequently or reliably enough. The weekly or bi-monthly tire checks simply don’t happen. Many fleets hire tire dealer personnel to perform the pressure checks on evenings and weekends when most equipment is idle. But some trucks and trailers are always missed and the quality labor required for this job is hard to justify in this cost-competitive marketplace.

Another consideration is time. With the recommended use of sealing valve caps, checking 18 tires on a typical tractor-trailer requires approximately 20 minutes. Visual checks, as well as tire “thumping” have been shown to be extremely unreliable at even estimating inflation pressures.

The idea of full-time pressure sensing has been around for some time, but most of these devices attach to the valve stem end and are damage-prone due to extended length. In some cases, they create an imbalance condition at speed. Also, most early designs had no remote readout, and thus relied on visual checks of each tire valve, with inside duals being the most challenging. Some light-duty vehicle manufacturers have attempted to identify low tire pressures by using the ABS speed sensors to compare speed differentials of tires across axles, using the theory that low inflated tires turn faster than higher inflated ones. However, this doesn’t work for modern radial truck tires, since the revolutions per mile don’t vary much with inflation pressure, as the steel belt package “rollout” is more dependent on tread circumference, regardless of inflation over a wide pressure range.

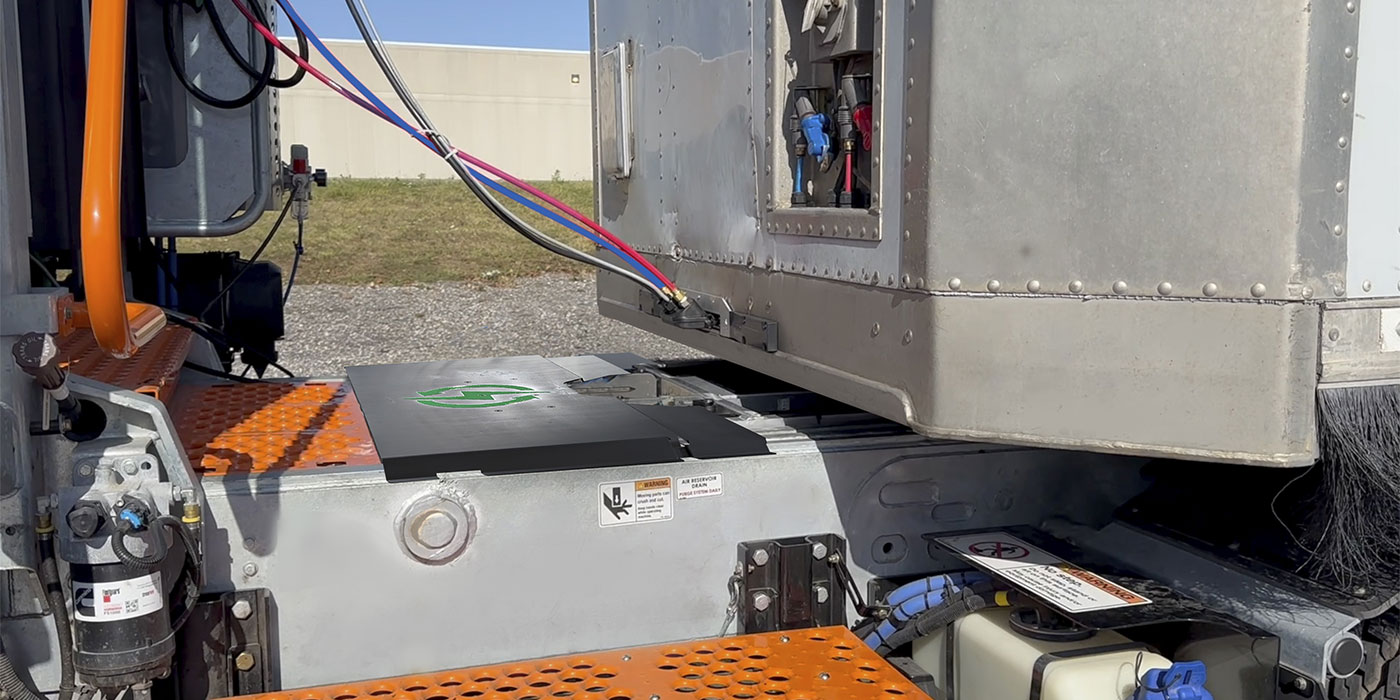

Recently, new tire pressure monitoring systems (TPMS), which have electronic advances and production cost efficiencies, have come to market. Features such as wireless radio frequency (RF) signal transmission, low power consumption circuitry, extended life batteries that last for five years or more, portable laptop programming, self-diagnostics, and robust packaging are now available.

Another obstacle being addressed is the change in tire pressure that occurs from “cold” to stabilized operating temperatures of the contained air volume. This is common in the 10 to 15 PSI range for over-the-road trucks. Some new TPMS offerings have algorithms that sense both temperature and pressure to rationalize the final reading to “cold” inflation (this “cold” refers to the industry standardized inflation recommendations at approximately 65-70 degrees F). By sensing temperatures and comparing pressure build-ups among different axle ends/wheel positions, any individual tire with low inflation can be identified.

Initially, some fleets expressed preference that corporate operations or maintenance, rather than drivers, receive the message of an on-highway low inflation condition, followed quickly by corrective instructions to the driver. Some TPMS systems, however, offer alternatives such as a management-by-exception approach that uses a yellow light/low audible warning to drivers of a low, but not dangerously underinflated condition, and a red/loud audible warning advising more immediate action. In normal operation, the system is silent and specific tire pressures are not displayed. Some systems offer a manual override when the truck is stopped that allows checking individual tire pressures as a pre-trip inspection, for example. My experience to date is that these electronic pressure checks are extremely accurate and reliable. Certainly, the variables of damaged/

inaccurate gauges, manual checking techniques, and the possibilities of creating “leakers” are eliminated. Daily driver or ready line pressure checks can be quick and universal. Visual tire checks for conditions such as cuts, snags, irregular wear, etc., remain essential to good tire programs, but in the near future manual pressure checks becoming obsolete on power units may be a big step in the right direction.