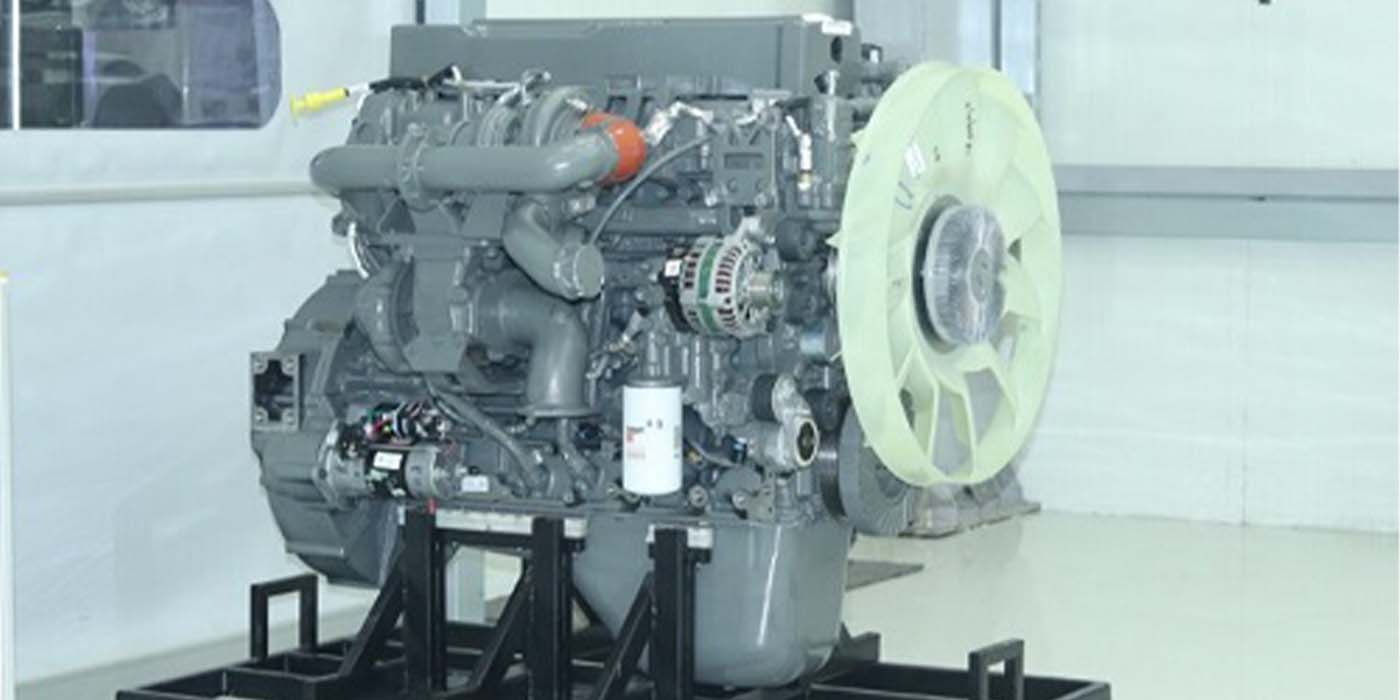

nology options. Data logging should be performed on each vehicle, with the documenting of exhaust temperatures under different duty cycles, such as vehicle routes or sporadic workloads.

To achieve verified emissions reductions, DOCs typically require a minimum exhaust gas temperature of 150˚ C, which is easily achieved on a wide range of engine models, years and duty cycles. The required minimum exhaust temperatures for passive DPF systems range from approximately 240˚ C for 50% of the operating cycle to 400˚ C for 30 minutes. Active DPF systems rely on an additional heat source and are therefore not dependent on the engine duty cycle and resultant exhaust temperatures.

3. Understand DPF regeneration requirements

DPF regeneration occurs when the filter element reaches the temperature required for combustion of the carbon in the Particulate Matter (PM). How regeneration occurs depends on exhaust temperature. “Passive” regeneration occurs when exhaust temperatures are hot enough to sufficiently raise the temperature of the filter element during the normal duty cycle. “Active” regeneration must be used when the engine exhaust temperature is not hot enough to initiate combustion, requiring an additional heat source to sufficiently raise the temperature of the filter element. The minimum frequency of regeneration is determined by the rate of PM build-up.

4. Understand DPF cleaning requirements

The removal of the ash from the DPF is done much less frequently than regeneration. Intervals for DPF cleaning vary from bi-annually to annually, or longer. Monitoring engine exhaust backpressure is the best way to determine if and when DPF cleaning is necessary. The need for very frequent filter cleanings may indicate incomplete filter regeneration or the need for maintenance. Periodic filter cleaning is necessary for both active and passive DPF systems.

In general, cleaning requires the manual removal of the DPF from the vehicle, heating the filter and using compressed air combined with a vacuum system to blow the ash from the filter and capture it in a sealed container. Professional filter cleaning services are available. Highly automated cleaning stations are also becoming available, allowing fleet service technicians to perform cleaning on-site.

5. Select a retrofit technology

Several factors determine which retrofit technology to install on vehicles, including the number of vehicles, the technical feasibility of installing various devices and maintenance requirements and capabilities. EPA’s list of verified diesel retrofit technologies quantifies the emission reductions achieved by each device and defines the specific engine operating criteria that must be met in order to successfully apply that device.

6. Select a technology supplier

To ensure retrofit technology compatibility, suppliers should review actual vehicle operating conditions and perform temperature data logging prior to retrofitting a vehicle. Fleets should obtain and store data logging records for all vehicles for later reference.

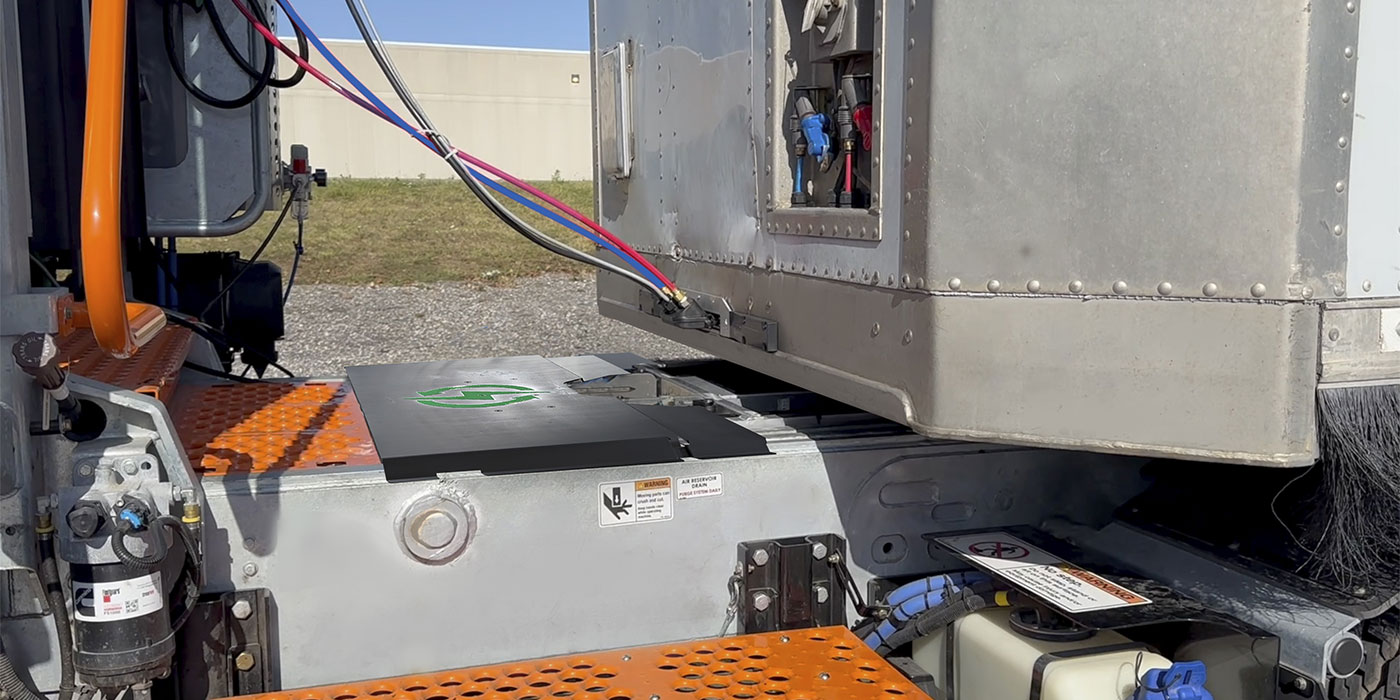

7. Install the retrofit device

Prior to installing any retrofit device, an engine inspection should be performed to ensure proper operation, including a check of the vehicle exhaust system’s integrity. Since a retrofit device typically weighs more and may be larger than the muffler, stronger clamps and brackets may be required in place of those used originally. To facilitate removal of the device for cleaning, quick-release clamps are often used. The time required for retrofit installation will vary and can range from approximately two to 12 hours.

In some applications, the retrofit device matches the dimensions of the conventional muffler and can be installed as a muffler replacement. In other cases, the space available for retrofit installation on the vehicle is restricted, and the configuration needs to be custom designed. Retrofit devices must be mounted within a set distance from the exhaust manifold, as specified by the manufacturer.

8. Monitor backpressure

As a DPF collects PM, the passage of exhaust gas through the pores of the filter element may be progressively blocked, causing an increase in exhaust backpressure. Engine manufacturers place limits on exhaust backpressures for engines. Therefore, an exhaust backpressure monitoring and notification system must be installed with every DPF. It is also important that all vehicle operators and fleet service technicians are properly trained to recognize and respond to high backpressure alert signals. In most DOC retrofit applications, there is no need for backpressure monitoring.

9. Maintain the engine

It is important to properly maintain vehicles and monitor fuel and oil consumption. A retrofit device, for example, may mask an increase in oil consumption or a poorly maintained engine may damage the device.

10. Special requirements for closed crankcase ventilation systems

Closed crankcase ventilation (CCV) systems are verified by EPA only when installed in conjunction with a DOC. CCV systems may have special mounting requirements to enable oil flow back to the crankcase. CCV system filter cartridges must be replaced periodically. Depending on the manufacturer, this frequency can vary from every 500 to 1,000 engine hours, or once a year, or at every oil change. Some CCV models will have a service indicator to direct a change in the filter cartridge.

11. Understand fuel standards and requirements

Ultra low sulfur diesel fuel (ULSD) required for highway vehicles is also required for all DPF installations and is highly recommended for use with all DOCs. Fuel additives should not be used, unless explicitly approved by the retrofit manufacturer. CARB has verified diesel emission control systems for use with biodiesel blends up to 20% of the fuel (B20). Fleets should consult retrofit system providers regarding the use of biodiesel.

Verified technologies

The EPA list of technologies that have been approved for use in diesel engine retrofit programs includes Cummins Emission Solutions and Cummins Filtration DOC and CCV systems for non-EGR model year 1991 to 2003 turbocharged or naturally aspirated engines. Also listed is International Green Diesel technology-Low NOx Calibration plus DOC with ULSD solutions for certain families of Navistar engines in model years 1999 to 2003. Other technologies on the EPA list include Engine Control Systems’ Purifilter, AZ Purimuffler and AZ Purifier, Johnson Matthey’s ACCRT, CRT and CEM solutions, and Lubrizol’s PuriNOx product.

Total system approach

Donaldson Co. is offering a range of solutions for on-highway diesel retrofit applications, including:

• Spiracle crankcase filtration system (CFS) allows the crankcase to be closed without degrading performance, eliminating 100% of engine crankcase emissions and reducing engine oil consumption. Independent studies have also found Spiracle improves in-cabin air quality. Spiracle CFS requires a routine filter change.

• Diesel oxidation catalyst (DOC) muffler is a direct replacement for most original equipment mufflers on four stroke, on-road 1960 to 2006 model year engines rated from 150 to 600 HP. The take-apart style DOC muffler provides easy access to the catalyst in the event of plugging. DOC mufflers remove 15% to 30% of PM, and meet engine OEM backpressure limits.

• Diesel multi-stage (DMF) muffler for 1991 to 2002 model year diesel-powered engines is approved for four-stroke, on-road diesel engines with a range of 150 to 600 HP. The DMF muffler uses a two-stage metallic filter to trap and reduce PM, reducing emissions up to 60%. The maintenance-free DMF muffler does not require routine ash cleaning, although a take-apart design allows easy removal of the filter section in the event of plugging.

• Semi-active electronic filter (SEF) muffler system is designed to reduce PM emissions by over 90%, as well as hydrocarbon and carbon monoxide emissions. The SEF muffler, which incorporates an electric heater to periodically burn PM captured in the DPF, is effective for colder engine duty-cycles and eliminates the need for data logging.

• Low NO2 filter (LNF) muffler and low NOx filter (LXF) muffler products are designed for select EGR and non-EGR on-road engines including LNF mufflers for model year 1993 to 2006 high NOx engines and LXF Mufflers for model year 2002 to 2006 low NOx engines. The passive technology relies on the engine to provide the heat necessary for DPF regeneration. Data logging of the existing vehicle is required.

Donaldson diesel retrofit technologies are also available with an emissions device monitor (EDM) that continuously monitors backpressure and temperature, and alerts the vehicle operator via an in-cab display when abnormal or undesirable operating conditions are detected. The unit’s removable memory module holds up to 500 hours of data to aid in analyzing operating trends and to support troubleshooting.

Access EPA’s Verified Technology List here.