Bendix Spicer Foundation Brake earns award for expansion of wheel-end facility

Bendix Spicer Foundation Brake LLC (BSFB) recently earned a 2019 Business Expansion Award from the Bowling Green Area Chamber of Commerce for expansion of operations at its wheel-end manufacturing facility in Bowling Green, Kentucky.

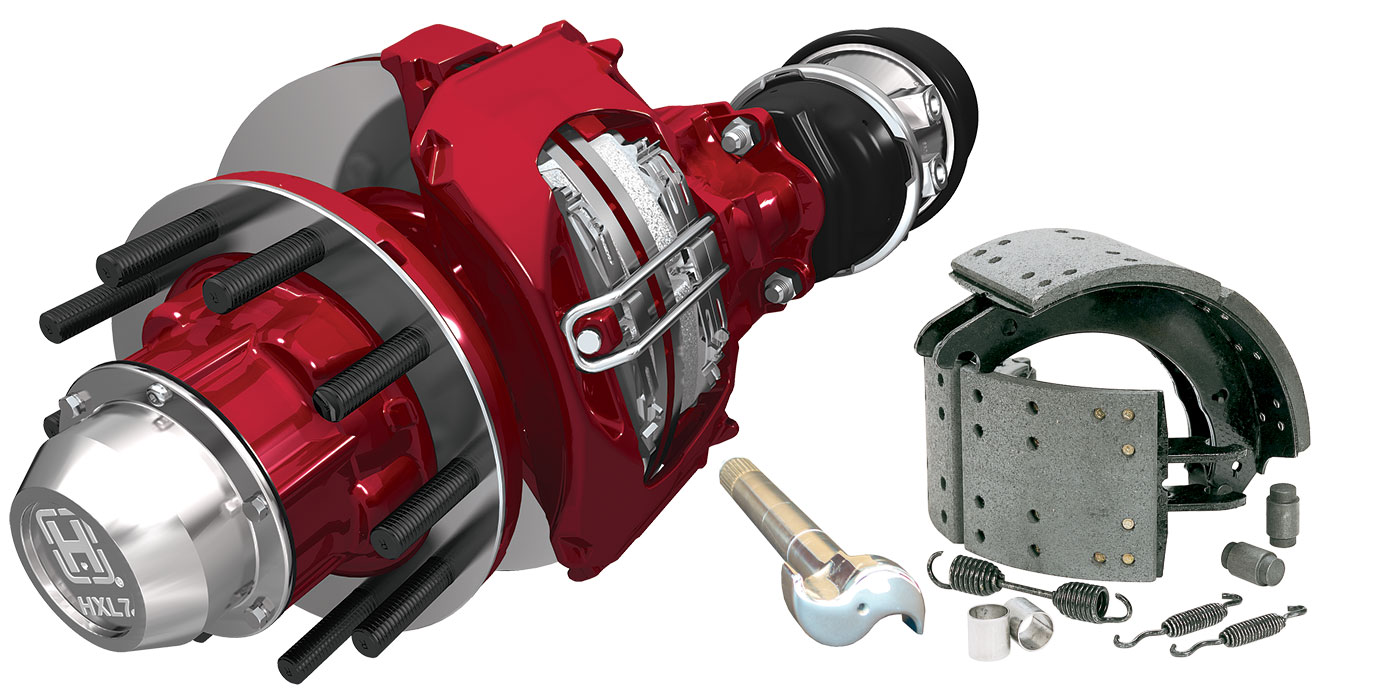

Online parts guide offered by Bendix Spicer Foundation Brake

To provide fleets, distributors and dealers with easy access to its Formula Blue line of hydraulic brake parts for light- and medium-duty Class 1 to Class 6 vehicles, Bendix Spicer Foundation Brake LLC (BSFB) launched the online Formula Blue Parts Guide.

Bendix offers tips to prepare for CVSA International Roadcheck

In 2019, almost two-thirds, or 64.4%, of the vehicles taken out of service during the Commercial Vehicle Safety Alliance (CVSA) International Roadcheck had violations related to brake systems, tires and wheels, and brake adjustment. Bendix says the statistic emphasizes the importance of foundational maintenance, and its role in keeping vehicles on the road and operating

Connecting brakes, wheel ends and other trailer components with telematics

The majority of fleet managers are used to the capabilities of truck telematics, but they may not be as familiar with trailer telematics, which are newer and just now starting to grow into their potential usefulness. Why have trailer telematics lagged behind their tractor brethren? It’s a complicated question, with an uncomplicated answer. “At the

Keeping an eye on brake wear

A vehicle cuts in front of your truck and stops abruptly. The truck driver slams on the brakes only to find that the truck’s stopping distance isn’t what it once was—these brakes haven’t been inspected recently. Without the proper stopping distance, an accident becomes inevitable. It’s an extreme example to be sure, but it’s just

Preventative maintenance to avoid brake wear

It’s important that your technicians are trained on how to spot brake wear, and that your shops have systems and schedules in place aimed at avoiding wear issues on brakes. “The only real way to keep an eye out for irregular brake wear is visual inspection on both drum and disc systems. Spotting irregular wear provides

Brake pad development heading into the copper-reduced era

Five years ago, an agreement between the EPA, states and automotive industry players was signed to reduce the use of copper in brake pads. Next year, brake pads will need to reduce copper to less than 5% by weight, and then less than 0.5% by 2025. There’s no magic button that will make this happen;

Bendix unveils wear sensing technology in air disc brake pads

Bendix introduced pad wear sensing on all versions of the Bendix ADB22X air disc brake (ADB), available for order on new equipment from select truck and trailer manufacturers. Bendix ADB wear sensing technology determines when a pad is nearing its replacement period and provides a signal via telematics that fleets can use to proactively schedule

Bendix announces improvements to ADB22X air disc brake

Bendix has announced several improvements to its ADB22X air disc brake. “Thanks to a new adjustment mechanism that’s engineered for increased vibration robustness while improving the running clearance between the friction and rotor, the new ADB22X improves pad life and reduces residual brake drag, which results in extended service life,” said Keith McComsey, director of

Truck brake fade: Why it happens and what you can do to minimize it

You apply the brakes and the truck stops. Simple. Until it’s not. Just about every truck driver is going to experience brake fade, which is most accurately and scientifically described as “the condition in which the thermal capacity of the braking system has been exceeded and the system operates at reduced effectiveness.” More to the