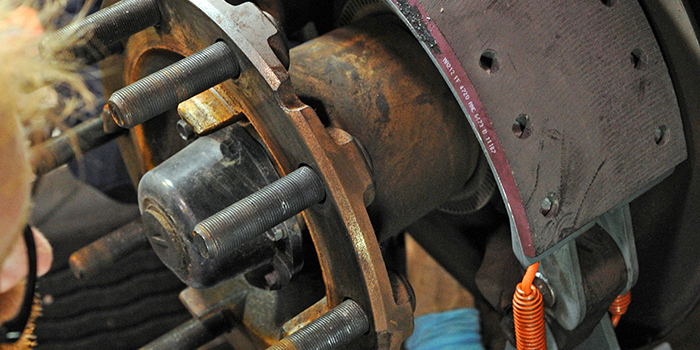

Preventative maintenance to avoid CSA brake violations

There’s a lot to remember when inspecting brakes; fleets need to make sure everything is operating properly, and that potentially costly CSA violations can be avoided. Fleet Equipment polled our experts from our CSA brake story on the steps they recommend taking in a brake inspection. Read the full story on common issues that lead to CSA violations,

Check your brakes: Putting a stop to brake-related CSA issues

Commercial Vehicle Safety Alliance’s CSA violations should be an unnecessary problem, especially since they can lead to costly delays, and unexpected downtime may cause fleets to lose customers not only because of delays. After citations related to lighting problems, brakes are the second most commonly penalized item—18.7% of violations handed out by the CVSA in

Bendix releases air disc brake designed for trailers

Bendix has announced the release of the ADB22X-LT air disc brake designed specifically for trailers. Bendix unveiled the ADB22X-LT in conjunction with Utility Trailer Manufacturing Co., the first builder to offer the new brake. “In the decade since Bendix introduced the first air disc brake to the North American commercial vehicle market, we’ve had many customers

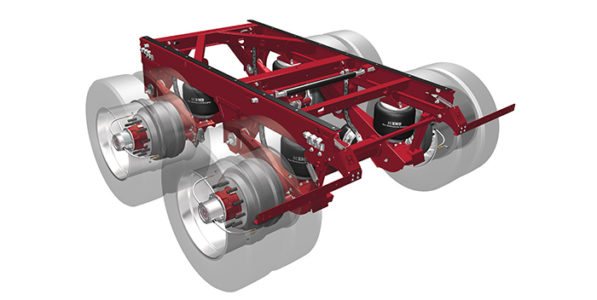

The inside scoop on spec’ing axles and brake ratings

For optimum performance and safety, brakes and suspensions need to be a match and work well together. So what do fleets need to know? Fleet Equipment asked major suppliers to provide the inside information.

Bendix expands Formula Blue line of hydraulic brake parts

Expanding coverage of its Formula Blue hydraulic brake parts line, Bendix Spicer Foundation Brake, LLC (BSFB) recently added 100 new part numbers, and plans to introduce additional parts every quarter. Formula Blue is BSFB’s comprehensive line of hydraulic brake parts for light- and medium-duty import and domestic vehicles ranging from Class 1 to Class 6.

Applying the brakes: Ensuring the future of truck safety

Advanced safety systems that employ radar- and camera-based technologies that enable adaptive cruise control and even autonomous truck operation rely heavily on one specific component—the brakes. The safety of these futuristic collision mitigation systems rests squarely on proper brake application, operation and maintenance. “It’s important to keep in mind that advances in collision mitigation technology

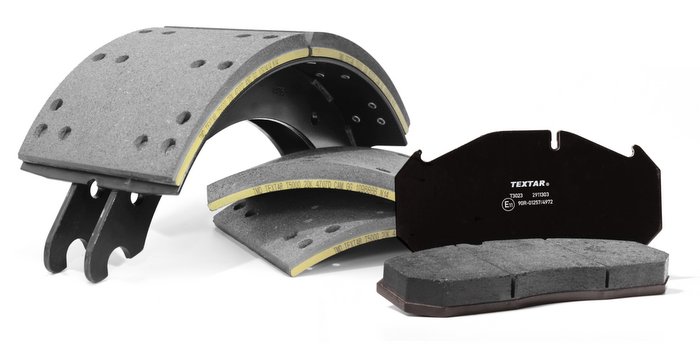

Aftermarket brake friction: Know what you need and what you are getting

When replacing brake friction material, Dan Dunkleberger, Haldex Friction’s product manager, says that fleets “need to understand the application, duty-cycle and environment in which the vehicle in is performing. These three key things will give the end-user the necessary information needed to spec the correct friction material for the job. Application and duty-cycle are also

Kenworth adds Bendix air disc brakes option for T370 medium-duty conventional

Kenworth Truck Co. announced that factory-installed Bendix ADB22X front and rear air disc brakes are now available for new Kenworth T370 medium-duty conventional trucks. “Fleets and truck operators purchasing new Kenworth T370s can now benefit from the automotive-like feel, lightweight design, ease of maintenance and superior performance offered by Bendix front and rear air disc brakes,”

Good friction: Replacing air disc brake pads

According to Rick Martin, senior manager of aftermarket training for Meritor, when it comes to purchasing replacement friction material for air disc brakes (ADB), there are some things fleets need to know—the most important of which is buying the same lining material the OEM installed on that vehicle; i.e, replace like for like. “OE brake

Good friction: Replacing air disc brake pads

Choosing the right friction material for air disc brakes is only one factor to consider when replacing pads.