For optimum performance and safety, brakes and suspensions need to be a match and work well together. So what do fleets need to know? Fleet Equipment asked major suppliers to provide the inside information.

Specifications

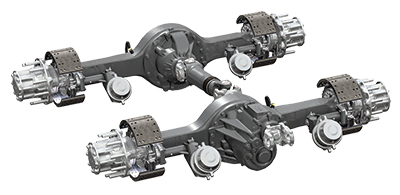

“Original equipment manufacturers [OEMs] are responsible for selecting the right brake for a particular axle based on gross vehicle weight rating [GVWR] and gross combined weight rating [GCWR],” says Steve Slesinski, director of global product strategy—planning and management at Dana. “The most important thing a fleet can do is to spec the right axle. It is very important to know the application and duty-cycle requirements of your vehicle. How will the truck be utilized, and under what operating conditions? Talk to your OEM about which components are right for your specific needs.”

The National Highway Traffic Safety Administration’s Federal Motor Vehicle Safety Standards (FMVSS) dictate requirements for both air brakes and hydraulic brakes on all types of on-highway vehicles. FMVSS 121 and FMVSS 105 detail the brake performance, equipment, and dynamometer test requirements applicable to trucks and trailers including stopping distance and parking brake regulations. It’s up to OEMs to ensure that vehicle stopping distance requirements are met.

The whole system

“The Federal Motor Carrier Safety Regulations [FMCSR] require that the OEM is responsible for compliance to FMVSS-121 for air actuated brakes,” says Bert Fisher, principal engineer of actuators for Haldex. “Each commercial motor vehicle must meet the applicable service, parking and emergency brake system requirements to ensure brake effectiveness under normal and emergency conditions. Based on the maximum required load, brake ratings are determined by the components that make up the system; brake model and whether it is a drum or disc, lining, size and stroke of the brake chamber, size of the brake adjuster and the amount of torque. The axle load rating determines what tires, wheel end brakes, brake adjuster, actuator are required.”

The brake performance involves every one of the system components all the way to the compressor—it’s the whole system that is involved.

“When specifying axles, fleets typically do not need to worry about brake ratings since all of the major OEMs have automatically matched the right brake ratings with the correct axle spec’s,” says Joe Kay, Meritor’s director of engineering and brakes for North America. “This is done because suppliers and OEMs working closely together to make sure those components are engineered to work properly. A proper brake rating will be correctly selected to match the correct axle spec. Suppliers work with OEMs to provide the right upfront-standardized spec. Optional features such as Meritor PlatinumShield to extend life are options that should be considered.”

Customer evaluation

T.J. Reed, Meritor’s general manager of brakes, contends that there are no correlations between axles ratios and brake ratings since, typically, brake choices are made up front by determining vehicle mass and speed utilized. “Meritor evaluates each customer individually and typically we have found that linehaul customers are looking for products that are lightweight, efficient solutions for linehaul vehicles; vocational customers need durability,” he adds. “Each application and customer is different and we assist them with finding the right solution for their applications.”

Determinations

“Brake ratings are determined by the selection of several components including brake model and lining, brake chamber size and stroke, slack adjuster length,” says Steve

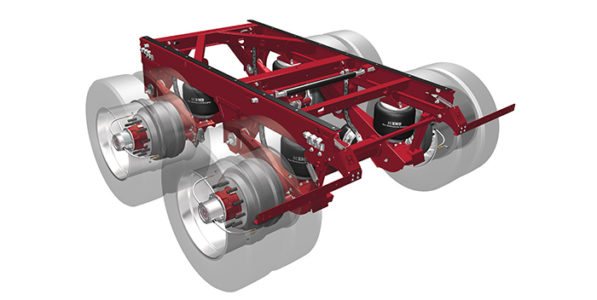

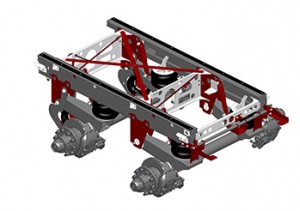

Hampson, director of truck business development for Hendrickson. “For optimum performance, brakes should be selected based upon the maximum required load and static loaded radius that is needed for the application. Hub, suspension, axle and tire ratings may all differ on a given trailer, and it is the minimum rated component of this group that determines the gross axle weight rating [GAWR].

“Hendrickson assembles over one million brake shoes each year,” he continues. “We offer a full suite of drum brake products designed to meet various applications including brake sizes ranging from 12.25-in. by 7.5-in. up to 16.5 by 8-5/8-in., standard and HXS Hendrickson Extended Service linings and a premium e-coat that comes standard on all drum brake assemblies.”

In addition to its drum brake lineup, Hendrickson also offers air disc brakes to accommodate this growing market segment and provides a superior level of performance over a broad range of operating conditions and speeds. “Our disc brake offerings include the optimized Hendrickson MAXX22T air disc brake system. In addition, WABCO PAN17 is now available for 17.5-in. wheels, and we will release the WABCO PAN19 system for 19.5-in. wheels later this year,” adds Hampson.