Foundation brakes

“There are numerous factors that play a role in brake approvals, going well beyond axle ratings,” says Gene Triplett, product director of foundation drum brakes for Bendix Spicer Foundation Brake. “The decisions made by the vehicle manufacturer on non-foundation brake components and systems have a significant influence on the selection of axles and brake sizes. These include, but are not limited to, tires, pneumatic system, suspension configuration, and factors affecting dynamic loading. On the foundation brake side, the OEM determines the best combination of slack adjusters, chambers and linings to achieve customer requirements and stopping distance. The OEM provides us with the application and requirements and we work to ensure that the brake will fit the vehicle design and application and deliver the desired results.”

“There are numerous factors that play a role in brake approvals, going well beyond axle ratings,” says Gene Triplett, product director of foundation drum brakes for Bendix Spicer Foundation Brake. “The decisions made by the vehicle manufacturer on non-foundation brake components and systems have a significant influence on the selection of axles and brake sizes. These include, but are not limited to, tires, pneumatic system, suspension configuration, and factors affecting dynamic loading. On the foundation brake side, the OEM determines the best combination of slack adjusters, chambers and linings to achieve customer requirements and stopping distance. The OEM provides us with the application and requirements and we work to ensure that the brake will fit the vehicle design and application and deliver the desired results.”

All brakes and axles work together efficiently; the proper selection depends on the customer’s requirements and application.

“Working together, Bendix and the truck manufacturer consider the end-user’s application to determine the appropriate axle and brake size that will deliver the maximum amount of lining wear, safety and stopping distance required,” Triplett adds.

Matchups

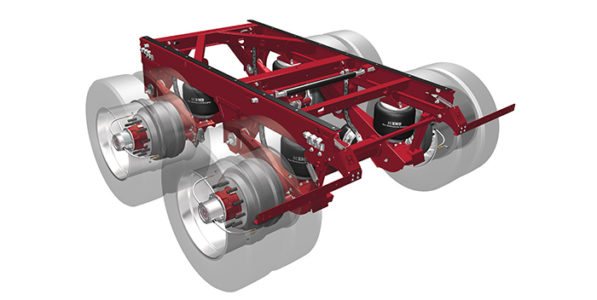

“Brake rating is only one factor in the gross axle weight rating,” contends Ken Wall, chief engineer for Reyco Granning Suspension. “Other important factors include axle beam ratings and suspension ratings. As for the brake style: If disc/drum brakes are requested by the customer, then the rating is based on that axle/suspension’s capacity and intended use.”

When working with customers, Rob Clements, senior project engineer at Reyco Granning, explains: “We try to find out as much information as possible from the customer. For example, what application and in what conditions will the vehicle be used? Taken in to consideration are: vocation, duty-cycle, vehicle information [number/configuration of axles, ride height, frame style], drive axle information/dimensions, etc. We use that information to narrow down what type of suspension would best suit the customer. Sometimes this will be an existing suspension [common in auxiliary axles], sometimes a variation of an existing suspension [common in drive axle suspensions], and sometimes it will require a completely new suspension to be designed. When a variant or new suspension is needed, we work with the customer to ensure that the new suspension meets the customer’s requirements with regard to fit, function, packaging, installation, and customer/end-user support.”

“Brake ratings are included in trailer GAWR calculations designs,” says Chris Helmer, director of applications engineering—Americas and trailer suspension systems at SAF-Holland. “The GAWR along with the axle spacing are used in the bridge law calculations.”

“The North American market place offers several brake pad ratings, typically 20K, 23K and 25K brake ratings,” adds Bill Hicks, director of product planning for the Americas at SAF-Holland. “Thus, the trailer OEM has the ultimate responsibility per the serial tag located on the front of the trailer to ‘rate’ the axle. This is found in the axle rating section and is normally 20,000 lbs. per axle. That being said, the suspensions themselves could be rated at higher capacities—23,000, 25,000 or even 30,000. However, the serial tag rating will be limited by the lowest rated component in the system. It is not uncommon for a 23,000-lb.-rated suspension to have 20,000 rated linings, thus the serial tag rating is 20,000 lbs. per axle.”

“The North American market place offers several brake pad ratings, typically 20K, 23K and 25K brake ratings,” adds Bill Hicks, director of product planning for the Americas at SAF-Holland. “Thus, the trailer OEM has the ultimate responsibility per the serial tag located on the front of the trailer to ‘rate’ the axle. This is found in the axle rating section and is normally 20,000 lbs. per axle. That being said, the suspensions themselves could be rated at higher capacities—23,000, 25,000 or even 30,000. However, the serial tag rating will be limited by the lowest rated component in the system. It is not uncommon for a 23,000-lb.-rated suspension to have 20,000 rated linings, thus the serial tag rating is 20,000 lbs. per axle.”

In other words, suspension and/or axle capacity ratings cannot be assumed to be equal in brake rating dependent upon the friction material selected. The serial tag rating on the front of the trailer is the determining factor.

“When working with our customers to help them match axles and brakes for their applications, we start with the suspension choice to make sure we can support the loads. This leads us to an axle structural capacity based on the axle diameter,” Helmer adds, “With these limits we can determine an acceptable brake rating choice for the combination and application.”

SAF-Holland aims to expand the air disc brake market. Click here to watch the video and see how.

“When choosing the correct brake for a vehicle combination it is important to size the brake and actuation to match the load carrying capabilities of the axle,” says Hendrickson’s Hampson. “This ensures smooth, balanced braking in normal operation while providing optimum stopping performance in critical conditions.

“Most North American on-highway applications only require brakes rated to 20,000-lb. GAWR,” he continues. “Suspension components may be specified at higher ratings for increased durability purposes, however, higher rated brakes [above 20,000-lb. GAWR] should only be selected when running at higher permitted loads. Using an overrated brake performance on your trailer can lead to excess brake torque, which can result in premature tire and brake wear, noise and trailer hop.”

The MAXX22T air disc brake system was designed for optimal performance at 20,000-lb. GAWR, the most common GAWR for on-highway applications in North America. “Where necessary, this system can also be rated up to 23,000-lb. GAWR without sacrificing tractor-trailer work balance,” says Hampson. “Understanding operating conditions and how brake, suspension, axle and tire components work together are key to getting the best performance out of your braking system. Hendrickson works closely with customers to determine the best-suited brake [disc or drum] for each application. Our brake certification guide, L809, aids in the selection of the proper brake system and associated components for the specific application.”

An emerging trend

“As the trend toward engine down-speeding grows, engines running at lower RPMs require faster axle ratios with lower numeric values to maintain vehicle speed and performance,” Dana’s Slesinski says. “These faster axle ratios result in less retardation in the drivetrain to slow the vehicle down at highway speeds, putting more demand on the brakes and requiring them to do more work.”

This is another example of the importance of spec’ing the right axle for your application so the vehicle manufacturer can select the appropriate corresponding brake. Five years ago, a typical axle ratio for a linehaul specification was 3.55:1. Today the popular 2.64:1 ratio results in approximately 25% lower driveline RPM and decreased engine brake performance. Furthermore, the use of low-rolling resistance tires and significantly improved vehicle aerodynamics can affect brake stopping distance, which may help explain the significant increase of disc brakes being installed on axles.

“At Dana, we have dedicated territory sales and service managers who can work with both OEMs and fleets to answer questions and provide guidance,” Slesinski adds. “Our partners at Bendix Commercial Vehicle Systems also have field service support professionals to help with specifying foundation brakes.”

Ultimately, the OEM is responsible for vehicle stopping distance. Communication with your OEM during the spec’ing process is vital to ensuring that your fleet’s performance, safety, and cost-related needs are met.

Throughout the lifecycle of the vehicle, fleets should use OEM or original supplier-specified components when performing service and maintenance. For example, when changing brake friction mechanisms, servicing wheel ends or other axle components, genuine original-equipment parts can offer the same level of quality, reliability, and performance as the original vehicle design, Slesinski notes.

Making a brake choice based on needs

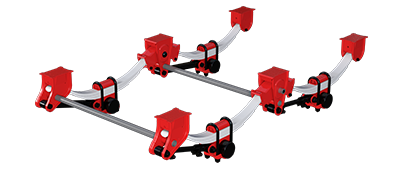

“Quite simply,” begins Steve McDonald, applications engineer for Hutchens Industries, “the function of the Hutchens suspension is to attach the axles to the frame. It is designed to be neutral a factor in brake operation and it has little, if any, effect on the axle performance. As a result, Hutchens does not make recommendations on which axle should be used, especially from a brake performance standpoint. Our suspension accommodates all common, and many uncommon, axle sizes currently available.

“Quite simply,” begins Steve McDonald, applications engineer for Hutchens Industries, “the function of the Hutchens suspension is to attach the axles to the frame. It is designed to be neutral a factor in brake operation and it has little, if any, effect on the axle performance. As a result, Hutchens does not make recommendations on which axle should be used, especially from a brake performance standpoint. Our suspension accommodates all common, and many uncommon, axle sizes currently available.

“With the Hutchens suspension, the trailer manufacturer can make their axle/brake choice based on the needs of the trailer application with little concern whether the suspension will be a factor,” he continues, adding that the only point at which the suspensions come into play with the axle application is either the clearance required between axle and frame or between suspension and axle components.

When it comes to axle clearance in relation to the trailer frame, McDonald adds, “The only recommendation we offer is to have 4² of vertical clearance between the axle and any trailer structure. This ensures that the axle will not bottom out on the frame during operation. As for component clearance, the basic brake design has not changed since the inception of drum brake axles. The spring suspension was developed around that design. Those factors combine to ensure that spring suspensions will fit most, if not all, drum brake applications.”

Installing disc brakes can be a bit more challenging. The brake chamber is located out-board at the tire and can intrude on the suspension. In overslung axle (spring over axle) configurations, the axle can be rotated to clear the suspension components and operate without issue. In typical underslung (spring under axle) installations the brake chamber either doesn’t clear the suspension or it lacks sufficient room between it and the frame to allow the suspension to deflect.

As required, McDonald says, Hutchens will work with the trailer and axle manufacturer on a case-by-case basis to help determine a possible solution.