I recently asked a driver how often he crawled under his rig to check the air pressureon the inside duals. He laughed and said, “You mean how many times a month or ayear.”

Lest you think I am driverbashing, I bet if we asked maintenance technicians the same question, theiranswers might not be much different. Let’s face it: No one wants to crawl undera tractor-trailer, even on a nice day, to check inside duals.

But tires account for amajor portion of a fleet’s operating expenditures. They are expensive to beginwith, and inadequate maintenance procedures can cause premature failure thatmay lead to unbudgeted road calls and also may eliminate the casing as a viablecandidate for retreading, adding to overall cost. In addition, tires that areover- or under-inflated are known to deliver poor fuel economy.

Because tire costs andmaintenance are a concern for fleets, Fleet Equipment has devoted this issue totires. In his feature, Adequate Pressure, Tom Gelinas, editorial director,takes a look at tire pressure monitoring systems. In our “Spec’ing for…”feature, written by Senior Contributing Editor Seth Skydel, the emphasis is onspecifying tires for fuel economy. Our “Equipment Technology” feature is allabout tread and retread designs and application/position-specific tires. Inthis article, major tire makers and retreaders talk about new technology andthe specifying choices fleets have today that may help lower overall operationcosts.

Tires come in second only tofuel as an equipment operating expense for commercial fleets. But, unlike fuelcosts, fleets can do something about the tire expense portion of theirbusiness. It’s all about specifying the right tires and maintaining themproperly, which includes keeping the tire air pressure on all wheels at themanufacturer’s recommended levels.

According to tire suppliers,an inflation mismatch greater than just 5 psi means that the two tires in adual assembly will have a significantly different circumference. But, becausethey’re attached, they have to cover the same amount of road in a singlerevolution. So, the larger tire drags the smaller one. The result is irregularwear, which means at least one of those tires will need to be replaced beforeit has reached its expected service life.

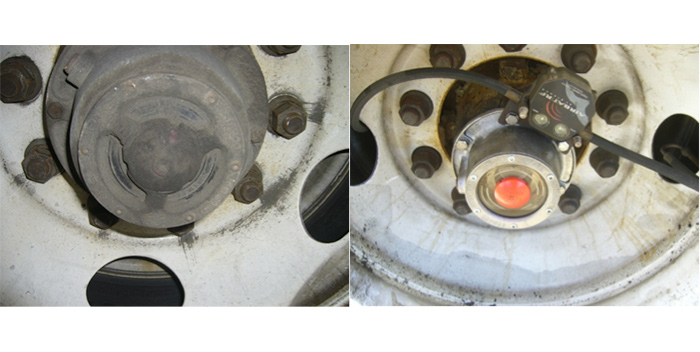

So,if you can’t get your drivers or technicians to crawl under those duals tocheck tire pressures, why not get your tire supplier involved in a tiremaintenance program, which could include regular air-pressure checks? Or,perhaps the purchase of a tire pressuring monitoring system could be in yourfuture. Whatever your plan for achieving and maintaining better tire airpressure control and tire maintenance, now is a great time to start takingbetter care of those assets.