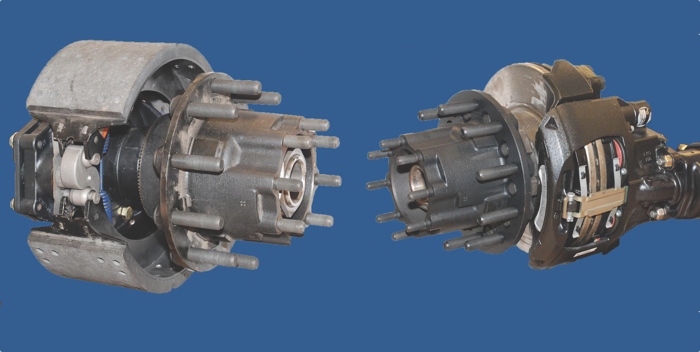

When deciding on specs for a commercial truck, the braking system is one of the most important components to consider. There are several aspects to think about, but one of the first decisions is most likely going to be between disc and drum brakes. Each type has pros and cons that will impact different users in differing circumstances.

The main strong point for disc brakes is reduced stopping distance. With disc brakes, that distance can be anywhere from 17% to 33% shorter than drum brakes, depending on speed. This is especially important in regard to federal braking standards for heavy trucks. Reduced fade is another benefit, especially for vehicles that have more frequent stopping events. Also, service and maintenance on disc brakes is typically simpler and faster than on drums. But even with all of these benefits of disc brakes, drums have their positive points, too.

Compared to disc brakes, drum brakes are generally more durable, requiring fewer lining replacements in a given period. They also provide better balance with trailer braking systems (which typically use drums), aiding stability. And, with their popularity in the market, replacement parts for drums are typically cheaper due to a larger economy of scale.

Outside of these general comparisons, the vehicle’s intended use will have the biggest influence on which brake type to choose. The fade resistance of disc brakes makes them better suited to vocational trucks that have to navigate work sites. On the other hand, the superior durability of drum brakes makes them a good choice for long-haul trucks that benefit from longer service intervals.

All of the benefits of either braking system will only be realized with proper maintenance. It’s important to note that each system will differ slightly from manufacturer to manufacturer, so it’s vital to have the proper guidelines available for continuous maintenance. One source for this information is Mitchell 1’s TruckSeries software, which provides specification charts needed to service the braking systems found on various commercial vehicles, along with maintenance, troubleshooting and repair information.

This article was contributed by Julius Hairston, technical editor for Mitchell 1’s Commercial Vehicle Group. Additional tips for repair and maintenance of Class 4-8 trucks can be found in the Mitchell 1 ShopConnection Truck blog.