Technology changes always bring with them a shift in maintenance practices. When it comes to maintaining equipment these days, we’ve heard there are new considerations, which are catching the attention of fleet mangers.

One of our readers writes that since the 2004 EPA engine emission regulation, which introduced EGR technology, the fleet has had to include several new checks during PM inspections. It now has priority inspections on fan hubs, idler pulley belt tensioners and all front-end components. The fleet manager says his technicians are finding that the increased heat in the engine compartment is causing a lot of these front engine parts to fail more quickly than before. In addition, he notes that now the fleet has to clean out the seventh injectors at least once a year, or there are issues in the cold weather (seventh injector is located in the DPF). He adds that the fleet is currently doing this work in-house.

We have also heard from another reader that he has been worried about the significant increase in equipment corrosion over the past several years. He says, “We are asking our technicians to increase their awareness on what corrosion is doing to all components—especially electronics.” In addition, he says, because of increased corrosion, the fleet has seen a life expectancy drop in lift gate platforms, as well as coupler plates.

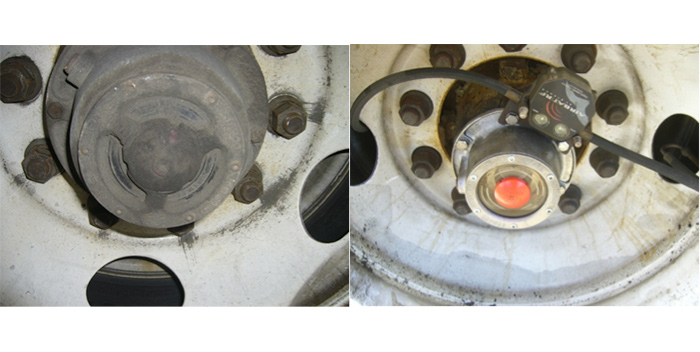

He goes on to say that other maintenance considerations remain “business as usual” with a couple of new twists. For example, he notes, “I have been checking hubs and bearings the same way for years, but eight years ago I adjusted and pulled the caps to visually check for moisture in semi-type fluid. We also jack-up the trailer and do an axle rotation of each wheel at specific intervals depending on the operation. I now take a closer look at studs and I am finding that some are of low quality. In addition, I have been torquing unilug nuts to 550 ft./lbs. for 25 years, and just went last year to 600 lbs. and 650 lbs. on refuse trucks last year.”

For many fleets, DPF and overall newer engine maintenance is still out for debate—specifically when to do it. On this topic, one reader writes, “I think we need to be more proactive and I think we don’t have enough history yet with these to determine the proper time to exchange DPFs.”

This reader also believes that, “The jury is still out on how long turbos or injectors will last, but they will become a maintenance item.”

So, what are your concerns? Fleet Equipment would like to know what other readers are experiencing so it can address these concerns in upcoming issues of the magazine. Please send me an e-mail, or fax us at 330-670-0874, outlining the maintenance issues that are changing the way you do business today.

Fortunately, as more equipment changes occur, fleets have access to industry associations, like the Technology and Maintenance Council of the American Trucking Associations, the Private Truck Council and the National Truck Equipment Association, which empower fleet managers and industry equipment makers and suppliers to work together and learn from each other. If you are not a member of one of these associations, consider joining to stay better informed.