Few experienced fleet managers would argue with the idea that a good preventive maintenance (PM) program, properly performed and done in a timely manner, will save money. In fact, some of the best equipment managers say that the most important activities in their shops are those done during a PM. A fleet with an effective PM program will have its trucks spend less time in the shop, will experience few to no breakdowns on the road, and trucks will likely provide either a longer service life or greater disposal value compared to a shop that views preventive maintenance as a burdensome requirement.

If preventive maintenance is expected to save money, will shortening PM intervals and doing more of this money-saving activity save even more money? Definitely not! Too much PM, like too much of anything, will not provide better results than a PM program optimized for your fleet. Wouldn’t it be great if someone could give you a PM program for your fleet?

As a matter of fact, there is one—the program recommenced by the OEM that built your truck. But, you may ask, is it an optimum program for the vehicles in my operation? Does it take into account the changes in lubricant products currently available if it is built around OEM oil change intervals, as many PM programs are?

At least one engine manufacturer is coming out with products that do not require an oil change for 50,000 miles, but that does not mean the rest of the vehicle shouldn’t be seen before the engine’s next lube change. Darry Stuart, president and CEO of DWS Fleet Management Services, says, “My belief has always been that there is plenty of life available in the oil. However, we still need to do a good PM inspection so the vehicle can get to the next PM without a problem under operating conditions that are normal for that vehicle.”

With 50,000 mile oil change intervals, the challenge will be to make sure a truck will get to the next PM without a problem. If a unit accumulates 10,000 miles per month, it would be fully five months before it would be scheduled to come into the shop. That’s simply too long. Truck OEMs generally recommend service intervals based on component life cycle information provided by their component suppliers. The majority of schedules are developed based on industry recommendations by groups such as the Technology and

Maintenance Council and powertrain component vendors.

Extending service intervals

Peterbilt engineers tell us that extended service intervals may be allowed under certain situations, but when considering extending intervals, operators should have an effective oil analysis program in place. It is also recommended that a “dry” service be included in the schedule between wet services to identify worn or damaged components before they fail on the road causing unnecessary expense and downtime. Always keep in mind that extending service intervals requires close monitoring and it may impact overall life cycle performance.

Stuart says, “I believe it’s a very good idea to have a PM program that coincides with oil change intervals and requires nothing be done to a truck in between. But if we go to 50,000 mile drain intervals, it’s only a matter of time before some guys will push that to 70,000 miles. Then you’re going to have to do a dry PM somewhere in between––somewhere in the 25,000 to 35,000 mile range. I think that’s where we’re going to end up.”

Not all fleet managers make extending service intervals a priority in their operations. For example, David Foster, vice president of maintenance at Columbia, S.C.- based Southeastern Freight Lines, says, “We really don’t try to extend service intervals too much. We have basically three different schedules that are application specific.” All are wet PM services.

His P&D equipment is scheduled for service at 20,000 miles or 90 days, whichever comes first. Foster says that for most of these trucks, time gets them before mileage. The fleet operates a few smaller bore engines (like the International DT Series), which are on a 12,000 to 14,000 mile schedule because the shorter interval is recommended by the manufacturer. Foster says, “We have no intention of extending PM intervals for any of these trucks.”

Southeastern’s second group of trucks is referred to as line haul units, but the group is really made of combination vehicles because they are running line haul at night and P&D during the day. These units are all scheduled for service at 25,000 mile intervals. Foster says, “While that’s a rather lengthy interval, we monitor those trucks with oil analysis. These trucks used to be set at 20,000 miles. We were able to move that out as a result of our oil analysis. We saw no change in our analysis reports after increasing the interval.”

The fleet’s last group is its sleeper fleet, which truly operates exclusively in line haul duty. These trucks are serviced on a 30,000 mile schedule and also are monitored by oil analysis. Southeastern’s policy is to monitor 10% of every like group of trucks. When it takes delivery of a fleet, one tenth of them are randomly selected for regular oil analysis throughout their entire service life. Southeastern gets all of its oil analysis reports electronically. As a result, Foster says it’s easy to learn quickly about issues because problem information is flag-ged in the reports.

Oil quality

Stuart says, “I don’t like the term “extended drain intervals.” I believe it’s really optimizing lubricant life. Years ago, we had oil that simply wasn’t capable of doing the job delivered by today’s products. Today, we have lubricants that can perform very effectively beyond engine manufacturers’ recommendations.”

Yesterday’s oils needed to be changed at intervals that worked well with desirable PM inspection periods, so the industry built PM programs around the quality of engine oil. Nevertheless, many aggressive fleet managers made efforts to stretch oil change intervals. Stuart says, “When the industry was at 10,000 miles, I was at 15,000. When it was at 15,000, I was at 20,000. If we want to operate in an environmentally friendly manner, we need to use the oil for as long as we can. I’m among those who believe that oil never really wears out. It’s the additive package that dwindles over time.”

National truck leasing companies often provide leadership regarding maintenance programs, and many have extended their PM intervals on their medium-duty trucks. Intervals that used to be 5,000 to 7,000 miles are now running 15,000 to 20,000 miles. This is primarily due to improvements in today’s engine lubricants.

Stuart says, “Even oil that is not considered to be ‘top of the line’––let’s call it one level down–– is still high-quality oil. I don’t know of any engine failure that was the result of poor oil quality. There was a time that one brand of oil was described as keeping valve covers cleaner than other brands. I found that it did, but I never found that resulted in longer engine life or fewer problems. The difference comes down to distribution and

service.”

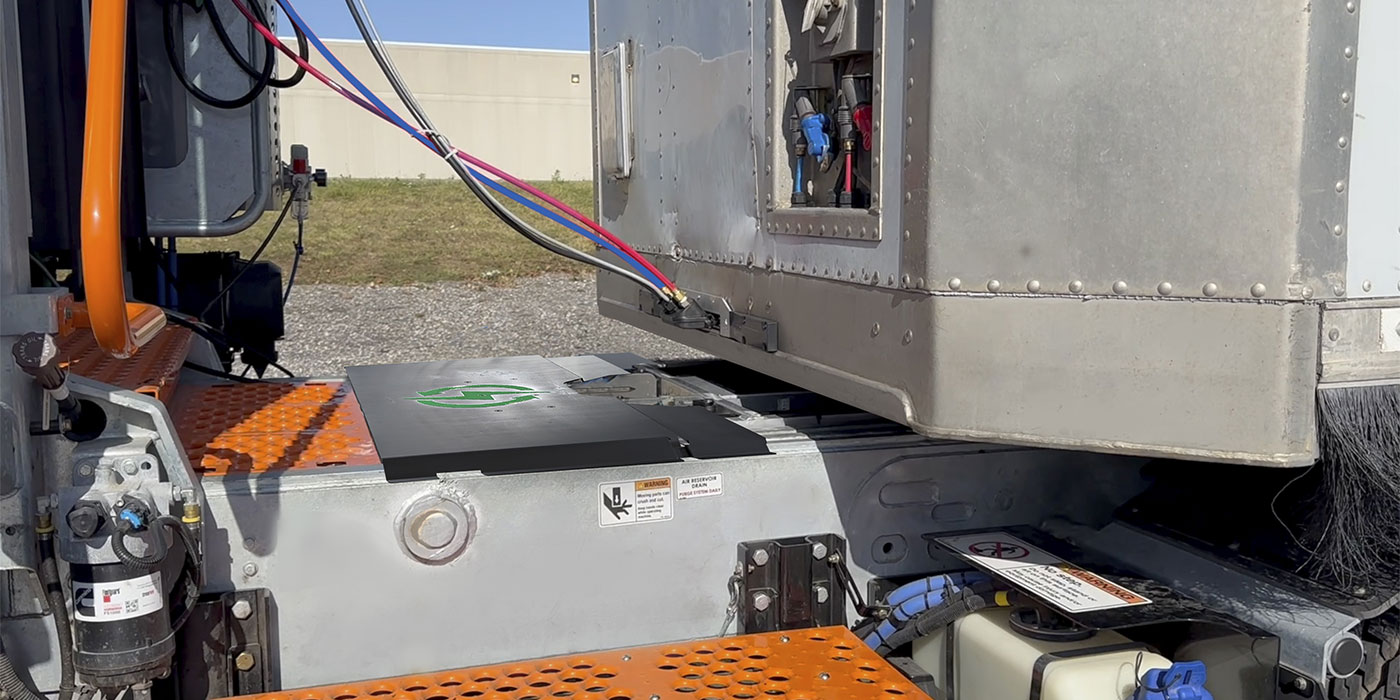

Trailers, too

If you’re interested in optimizing your PM intervals to save money, don’t stop at your power equipment. One of the biggest changes Southeastern has made in extending maintenance intervals has been with its trailer fleet. Trailers used to be on a 90 day schedule, but Southeastern has extended that to six months or 20,000 miles––allowed by a change to higher quality grease produced by Mobil specifically for extended service intervals.

Foster says, “We knew we could save a lot of money by extending this interval and still feel comfortable that it would not be detrimental to our ability to serve our customers as a result of unexpected downtime. All of our equipment goes through a check lane every time it gets dispatched, either inbound or outbound. While the driver is fueling, we have a technician looking at lights and brakes and crawling under the unit. Regular air pressure checks have helped us eliminate unscheduled downtime from tire problems. We touch our trailers a lot.”

A thorough inspection

So what should be included in every PM inspection––wet or dry? In addition to the common items, Stuart says to take the weight off the front axle when it is greased. Radiators should be pressurized. Complete vehicle wheel alignments need to be included; batteries need to be cleaned and load tested. He adds, “I still like carbon piles, but I’m also using electronic meters. Some are excellent, but I’m not yet convinced that they don’t leave the possibility of error.”

Foster says, “We work very hard to have all of our service scheduled. Unscheduled downtime is very expensive. Our goal is to eliminate all of it. We monitor our breakdowns to determine where we’re having issues. We pay very close attention to PMs and spend days training an incoming technician. We ‘Southeasternize’ them before setting them loose.”

An ineffective PM program will definitely cost a fleet money. Peterbilt engineers say you can expect increased expense due to unscheduled repairs, a degradation in component life, an increase in component failure and, of course, a reduction in early problem detection.

Stuart says, “It’s not engine stuff that will get you. Problems will show up elsewhere. A good grease will allow the driveline, kingpins, etc. to go the distance.” FE