How electrification will change truck service

Widespread electrification hasn’t happened yet, but even the most skeptical observers would have to agree that it’s coming to trucking, in some form, soon. Whenever electric vehicles do become more commonplace, fleets will need to be ready for the differences between those and the diesel trucks they’re used to—and just as importantly, technicians will too.

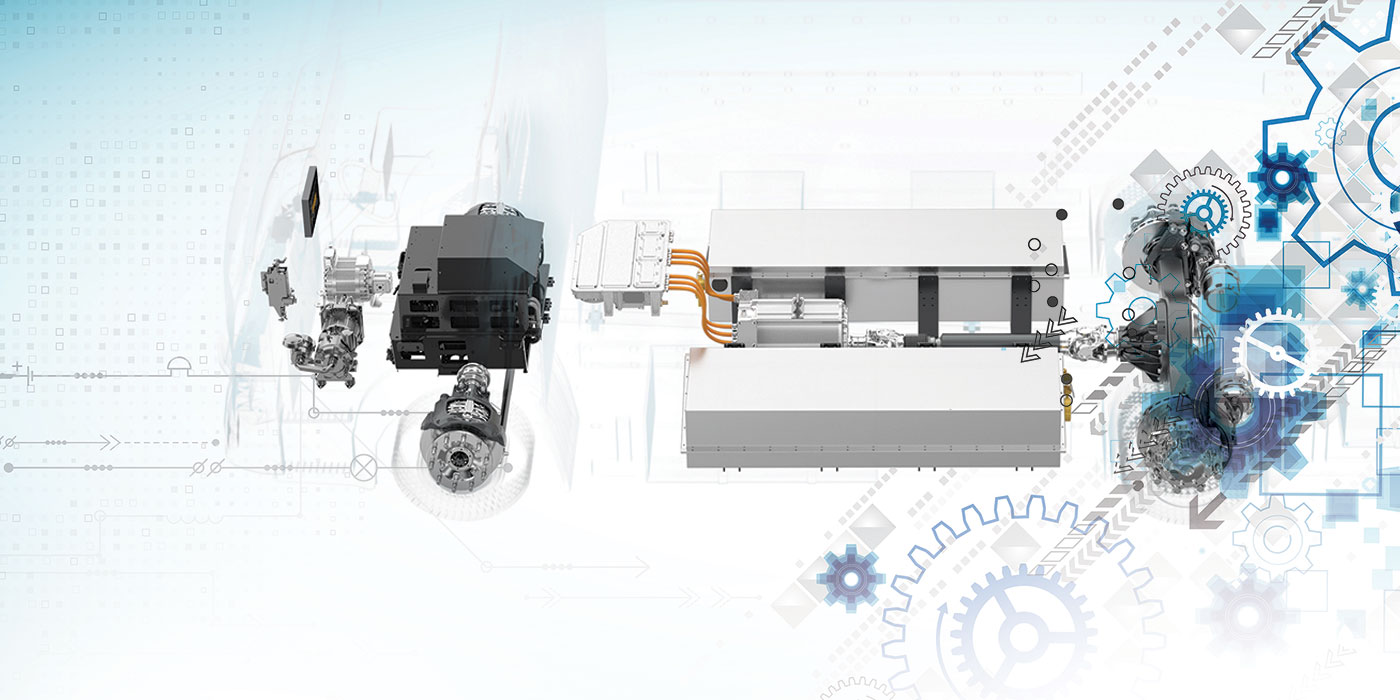

A reduction in gears: Inside electric truck transmissions

Rather than the typical 18-speed transmissions, electric trucks tend to use two-speed transmissions, with some using three or four. So why is that?

Photo Gallery: Heavy-duty Aftermarket Week—on the show floor

The fire and brimstone exploding from one of the The Mirage’s main attractions couldn’t match the energy on the Heavy-duty Aftermarket Week show floor. Headlines have been dominated by new products and new ways of doing things: Data, connectivity and innovation are driving themes at this year’s HDAW. Ater scrolling through this photo gallery, click

Jasper Engines & Transmissions names 2018 Supplier Award winners

Jasper Engines & Transmissions recently announced its New Part Supplier Award winners for 2018 performance.

The lowdown on engine components

A growing trend when it comes to engine oil is that many fleets are employing extended oil drain intervals for their trucks. This can be a time- and cost-saving practice, but only if your trucks are in an application that supports extended oil drain intervals. If it does end up being a smart move to go with extended oil drain intervals, know that your filtration system can handle it.

Advanced engine componentry enables efficiency improvements

An engine is a sum of its components. It’s a symphony of systems working together to produce power as efficiently as possible. Each engine OEM has its own strategy for achieving as much efficiency as possible. From turbochargers to waterpumps, no component is overlooked. There are two most commonly spec’d types of turbochargers used in

Reman turbochargers, starters and alternators

“Our reman process includes replacing damaged or worn parts with OEM-validated parts,” explains Thom Miles, BorgWarner’s manager of sales and marketing, N.A. aftermarket. “We recondition usable parts using innovative and environmentally-friendly salvage techniques. Assembly of BorgWarner reman turbochargers are done on advanced assembly lines that employ the same rigorous engineering techniques used for new production

Reman components

As fleets strive to maximize uptime and equipment life, reman components are becoming more popular.

Truck cooling systems

Today’s cooling systems are more than up to the task of handling the much higher levels of heat generated by emissions compliant diesels.

Fan drives and fuel economy

The cooling systems developed for today’s on-highway tractors are highly advanced. Design requirements facing manufacturers of fan drives must address the higher heat output of new emissions-compliant engine families. Vehicle aerodynamics, essential for improving fuel economy, can reduce the effectiveness of ram air and in turn generate the need for additional cooling from fans. Simultaneously,