According to Bendix Commercial Vehicle Systems, nearly one out of five commercial vehicles inspected during last year’s Commercial Vehicle Safety Alliance (CVSA) International Roadcheck were taken off the road. Bendix adds that issues with brake systems, service brakes and tires accounted for more than half of all the out-of-service vehicle violations across the U.S., Canada, and Mexico. The CVSA International Roadcheck 2024 inspection blitz is coming up May 14-16. Bendix offers tips to help fleets and owner-operators prepare.

Bendix tells us findings from the 2023 International Roadcheck show 11,270 of the 59,429 vehicles inspected—about 19%—were removed from roadways due to a critical finding related to vehicle safety. The company adds that problems related to the brake system or brake adjustment accounted for almost 40% of all out-of-service violations found, and tire issues raise that figure to 58%.

“Many of the critical issues flagged during these inspections are maintenance-related, and many are issues that could have easily been prevented with regular, thorough maintenance procedures,” said Fred Andersky, Bendix director of government and industry affairs and technical training. “That’s why keeping vehicles in good shape is critical in helping to maintain overall safety on the road, and why CVSA’s Roadcheck—along with a regular schedule of preventive maintenance—is so important.”

What is the International Roadcheck?

Established in 1988, International Roadcheck is a 72-hour, high-visibility, high-volume commercial motor vehicle inspection and enforcement initiative targeted at various elements of motor carrier, vehicle and driver safety. Commercial motor vehicle inspectors in Canada, Mexico, and the U.S. will conduct North American Standard Inspections of commercial motor vehicles and drivers at weigh and inspection stations, on roving patrols and at temporary inspection sites.

CVSA sponsors International Roadcheck with participation by the Federal Motor Carrier Safety Administration; Pipeline and Hazardous Materials Safety Administration; Canadian Council of Motor Transport Administrators; Transport Canada; and Mexico’s Ministry of Infrastructure, Communications and Transportation. Inspectors examine large trucks and motorcoaches, along with driver documentation and credentials, using CVSA’s North American Standard Inspection Program procedures.

Watching tractor protection systems

Bendix tells us that tractor protection systems are among the focus areas of this year’s Roadcheck. The aim is to increase awareness of these components—specifically, the tractor protection valve, trailer supply valve and spring brake valve. Officers will conduct inspections to confirm that the tractor protection system is functioning properly in the event of trailer separation.

“The tractor protection system inspection will vary based on the tractor protection valve that is in use on the vehicle,” said Brian Screeton, manager of technical training and service at Bendix. “The service data sheet for each valve is the best source for operational checks of that valve.”

According to Screeton, a basic, high-level test for a properly operating tractor protection system involves the trip pressures of the dashboard valves associated with the system. Begin by starting the vehicle and building full system air pressure. Then, shut off the vehicle, disconnect the glad hands, and push in the red trailer-supply dash valve button. Air will leak out of the trailer supply glad hand until the red button pops out. When the button pops, apply the service brake. No air should come out of the service glad hand.

Chad Benesh, technical support supervisor and member of the Bendix Tech Team, emphasized another crucial factor in the proper operation of the system.

“It’s vital to keep the glad hand couplings clean of contaminants that may get in them when not coupled,” he said. “Contamination in the glad hand has a direct path to the trailer relay valve, which can cause loss of brakes on the trailer as well as the potential that the brakes won’t release and will drag. Make sure dummy glad hands are used when glad hands are not connected. In addition, replace worn or cracked glad hand seals.”

Brake check

Brake systems accounted for 25% and service brakes 14% of the 2023 International Roadcheck out-of-service vehicle violations, yet many brake issues are easily preventable through routine maintenance and regular checkups, noted Mark Holley, Bendix director of marketing and customer solutions, wheel-end.

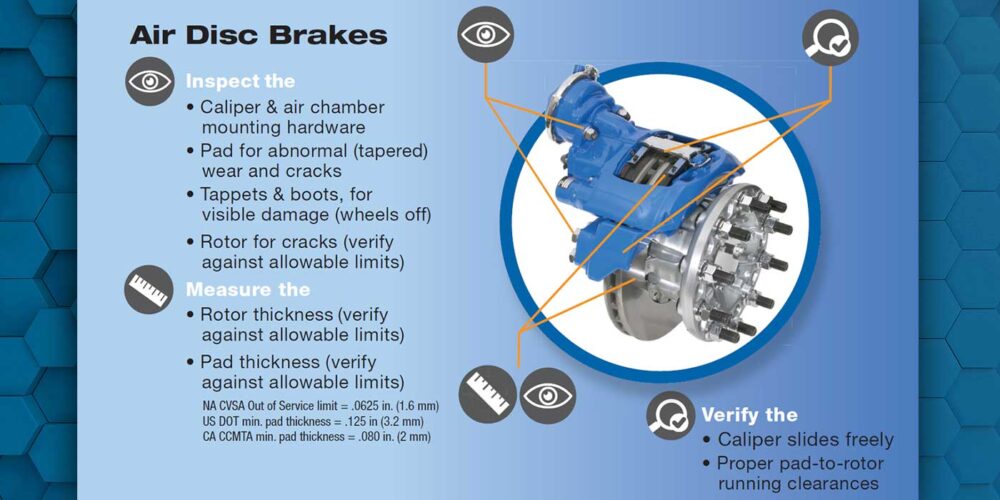

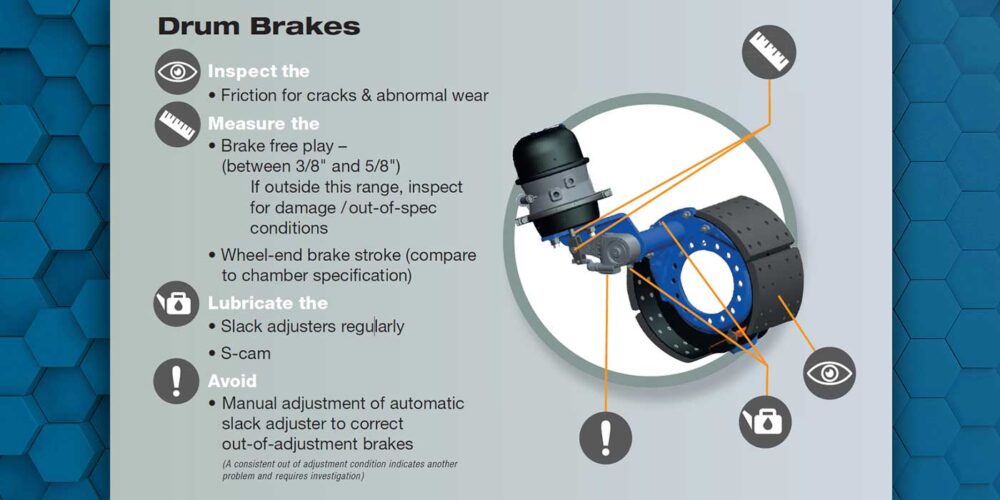

“First, drivers should always conduct standard walk-arounds—pre- and post-trip inspections—before and after hitting the road,” Holley said. “Look for visible brake system problems such as loose hoses or damaged brake components, air chambers or pushrods, for example. You can also spot adjustment issues if you notice slack adjusters that are extended at different angles on the same axle. Keep in mind that if you’re using air disc brakes, their internal adjustment mechanism significantly lowers the risk of out-of-adjustment violations.”

Earlier, in the shop, Bendix says air brake system inspections should include the following points, which relate to items typically inspected during Roadcheck:

- Conduct a brake application at a pressure above 80 PSI and listen for leaks;

- Measure chamber stroke at each wheel-end to ensure proper brake adjustment;

- Examine friction for good condition (no lining cracks, missing portions, oil or grease contamination) and minimum thickness; and

- Measure and inspect each rotor and drum for wear and heat cracking and/or leopard spotting.

“If you notice it’s time for new brake friction, make sure to keep things up to spec: Not all friction that is marketed as ‘acceptable’ under current Reduced Stopping Distance (RSD) regulations will actually perform to that standard,” Holley said. “Whether you’re replacing air disc brake pads or drum brake shoes, select components that will ensure the original equipment manufacturer (OEM) requirements are met so the vehicle remains compliant. If the friction needs to be replaced, it must be replaced on both sides of the axle.”

“Another critical point to remember: The performance of your braking system also affects the performance of connected safety systems,” continued Holley. “So, if the vehicle is equipped with a full-stability or collision mitigation system, it too can be negatively affected if brakes aren’t performing at their peak.”

The importance of TPMS

Roadcheck tire inspections emphasize the importance of maintaining proper tire pressure. According to Bendix, industry research shows about 90% of tire failures can be attributed to under-inflation, and nearly half of all emergency service road calls are tire-related. During the 2023 Roadcheck, tire issues accounted for 19% of out-of-service vehicle violations.

“Driving on under-inflated tires generates higher internal running temperatures, and that situation can lead directly to tire blowouts,” said TJ Thomas, Bendix director of marketing and customer solutions, controls. “Additionally, the added stress and excess wear and tear reduce tire life span. The American Trucking Associations’ Technology & Maintenance Council estimates that 20% under-inflation can shorten tire life by 30%.”

This risk can be reduced by using a Tire Pressure Monitoring System (TPMS), Bendix said. TPMS systems provide near real-time pressure alerts to the driver, which can help alleviate the problem of under-inflated tires.