What if there was a simple way to save as much as $1,000 per vehicle, per year on fuel and maintenance costs?

Depending on the state of your tires, there might be. That’s how much you could be losing out on just because your trucks and/or trailers are running on improperly-inflated tires, according to the North American Council for Freight Efficiency’s latest Tire Pressure Systems Confidence Report.

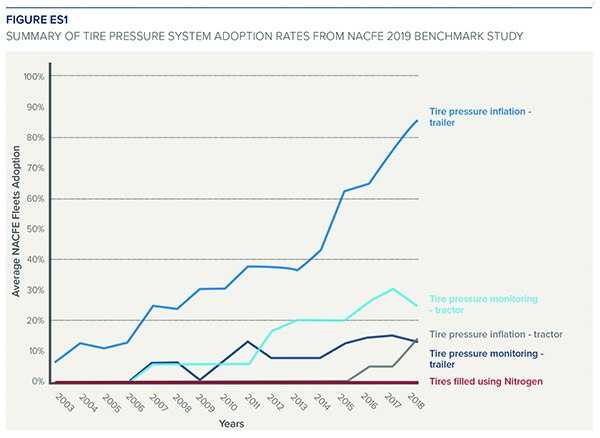

The simple solution is one that NACFE says has been proven to deliver safer, more reliable fleet operations: tire inflation pressure management systems like TPMS and ATIS.

According to NACFE, historical payback estimates for the implementation of tire pressure systems have ranged from less than one year up to about three years, with annual savings projected between $750 and more than $1,000 per vehicle per year.

If this kind of savings sounds too good to be true, consider first that the benefits of something as simple as maintaining the proper tire pressure are vast. Your risk of an unexpected breakdown decreases, and you’re less likely to damage other components on your vehicle. Your trucks will experience better fuel efficiency, reduced tire wear and longer casing life, giving your retread program higher value.

By taking advantage of today’s powerful telematics programs, TPMS and ATIS systems can be exponentially more beneficial to fleets than even just 10 years ago, says Jim Sharkey, vice president of global sales and marketing for Pressure Systems International.

“Avoiding under-inflation is the most important part of the ROI calculation for fleets. Not only does it save on fuel and tire wear, but avoiding a roadside service call will pay for the system,” Sharkey says. “Today, fleets should consider whether they run both ATIS and TPMS and connect it with a telematics system, in order to provide real-time information to the fleet’s operations.”

In this latest report, NACFE gave today’s commercial vehicle tire pressure systems its highest-possible confidence rating, adding there are “strong options for various truck duty cycles and fleet business models, and creative solutions continue to be developed for improved performance, better reliability and lower overall costs.”

While Sharkey supports these findings, he adds that tire pressure system installation alone won’t necessarily keep a truck’s tire pressure where it needs to be.

“When adopting this enhancement, [fleets] need to be sure that they have the resources to process and respond to the data. The value in having this ‘situational awareness’ can be tremendous, but it must be acted upon,” he says. “ATIS will keep a tire running, but it is not meant to be a long-term fix. Having both ATIS and TPMS data connected with telematics will bypass the driver and provide more detailed information on which tire needs attention, how long it was running with the issue and where it is located.

“Once these decisions are made, training for both the technicians and the drivers is extremely important. Once drivers have a better understanding on how the system works, they typically embrace it, instead of fighting it or simply not reacting to it.”

Have more questions on tire pressure systems? We answer many of those questions in this story.