Lift axles are required by state and Federal law to increase the gross vehicle weight rating (GVWR) of the truck to allow more payload to be carried, Heath explains. Allowable configurations vary from state to state. When deciding which to spec, it simply comes down to weight.

In addition to the potential fuel savings, lift axles can also reduce a fleet’s tire costs.

“Steerable lifts obviously allow for less tire wear than non-steer, especially when cornering fully laden,” Hendrickson’s Brown says. “Lift axles reduce wear on under-laden axles by removing them from the road up to 50% of the operational miles of the vehicle. Generally, overall tire maintenance costs will be reduced versus full time axles, though because of the many varying complexities related to vocation truck designs the savings may vary.”

“If your goal is not to maximize payloads for your operation,” Heath says, “you may be able to use fewer, higher capacity lift axles to reduce your tire costs.”

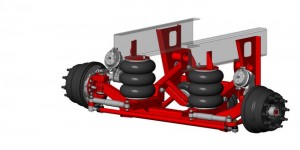

The impact on axle and suspension integration

When it comes to the impact spec’ing lift axles has on the integration of axles and suspensions, SAF-Holland’s Heath says that it is important to “think holistically. You may have the spec’d the perfect lift axle configuration for your operation, but if you failed to spec the right drive axles and suspensions, your warranty will be voided,” he says. “Or even worse, you will have durability issues. That means extra costs and down time. So, it is so important to work with your dealer on your entire truck spec.”

“With today’s modernization and the funding from the federal government, this allows the integration of axles and suspensions to be lighter yet stronger than they have ever been in the past,” says Brandon Covault, a Reyco Granning district sales manager. “This in turn, stretches budgets even further regarding fuel cost, tires, manpower and most importantly safety.”

“From a maintenance perspective, many fleets desire common components, so this influences system integration in a big way,” says Mark Dankow, Hendrickson’s senior engineering manager. “Such things as frame space, capacity, braking power and wheel/tire size are all considerations for how lift axles are integrated.”

Maintenance concerns

“Aside from bushings, bags and shocks, lift axles have some unique components that require servicing. Lift devices are one of them,” SAF-Holland’s Heath says. These are typically air powered. Many use air springs.

The NEWAY LSZ uses a proprietary SuperChamber design that is much more responsive and puncture proof. Like any steerable-beam-type axle, there are kingpins and tie rods to maintain. Most lift axles are not actively steered, and so they have steering dampers installed to help prevent an unsafe condition known as wheel wobble from occurring. It is important to replace steering dampers periodically with genuine OEM parts to keep this condition from happening. Lift axles also require somewhat sophisticated lift axle controls. It is important that these controls are functioning properly, or you could find yourself out of conformance with weight laws.

“SAF PosiLift and CBL lift systems are designed for low maintenance,” Hicks adds. “Air springs, lift mechanisms, and attachment points should be inspected as part of a fleet’s standard maintenance program.”

“As well as with many other vehicle components, lift axles must be maintained to ensure optimum operation,” Hendrickson’s Brown advises, adding that “these axles do not add ‘special’ or ‘unusual’ maintenance above and beyond a standard axle.”

“The most common maintenance concern is making sure that you are spec’ing the correct lift axle for the correct application,” Reyco Granning’s Covault says. “Having a properly rated axle ensures you are meeting bridge law requirements as well as providing a safe, durable unit.”