Eight tips to prepare your trucks for winter

Like it or not, winter is coming. You know the drill: falling temperatures, snow, and ice hitting large swaths of North America, presenting challenges for trucks and fleets. Now is the time to prepare. With harsh weather looming, this installment of the Bendix Tech Tips Series serves up eight pieces of advice for wheel-ends, air

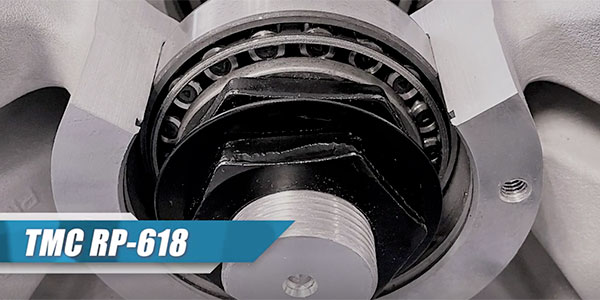

Tech tip: Proper truck wheel bearing adjustment

It’s important to know what the proper bearing adjustment is to reduce premature bearing failure. For optimal bearing life, you want to have an ideal bearing end-play setting between 0.001 inches and 0.005 inches in heavy-duty wheel-end applications. To eliminate the guesswork, the TMC RP618 was designed for heavy duty wheel bearing adjustment and allows

Tech tip: Case hardening vs. through hardening truck bearing components

Do you ever lie awake at night thinking about how to harden steel to the required level for bearing components? I know I do. And that got me thinking of how important it is for a fleet manager to know the differences between through hardening and case hardening. Iron mix needs a certain amount of

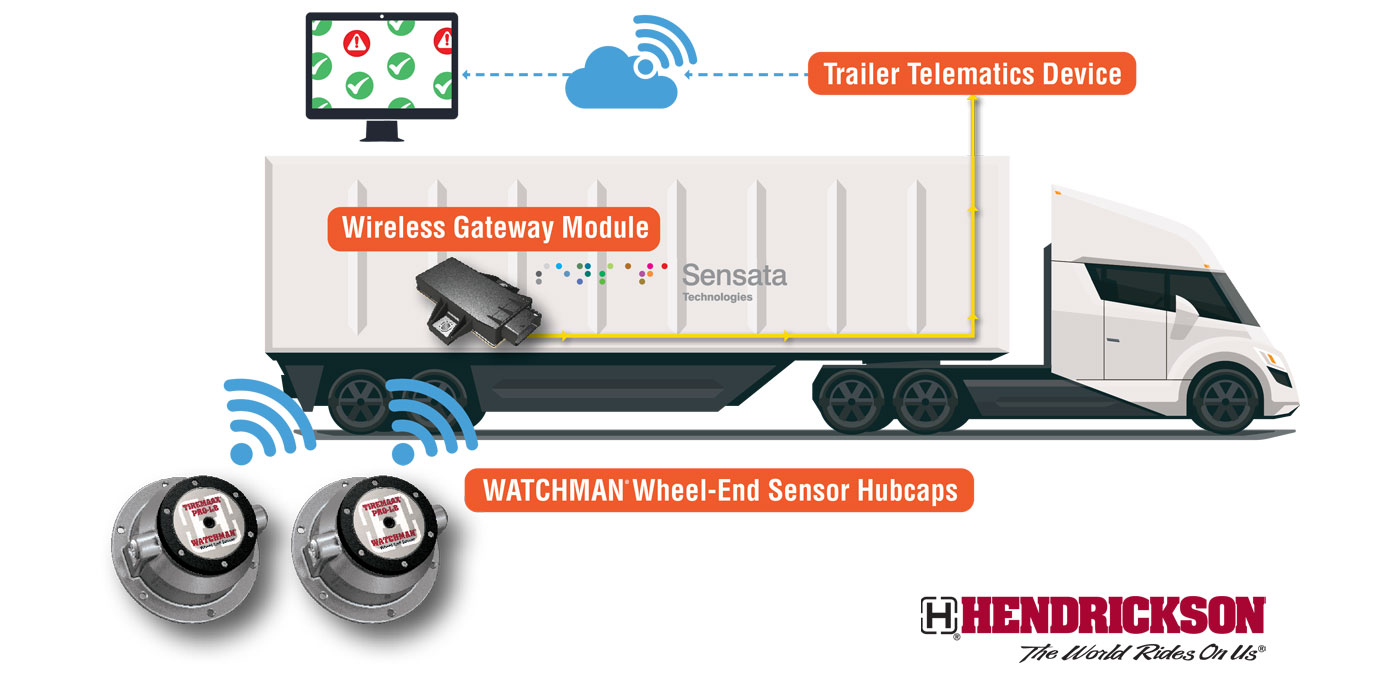

Hendrickson Watchman trailer wheel-end sensor technology launch plans move forward

Hendrickson Trailer Commercial Vehicle Systems is moving forward with launch plans for Watchman wheel-end sensor technology for trailers that operate on the vehicle area network developed by Sensata Technologies. The initial product offering will include trailer tire pressure and wheel-end temperature data that is communicated to the fleet via the trailer telematics system. It is

The 8 most common wheel bearing maintenance issues

Wheel bearings may not be the first item you think of when making your fleet’s maintenance checklist. There are bigger components—the engine, the tires, the safety system—that, just by their nature, demand more of your attention. But that does not mean that wheel bearings can be swept under the rug, as failures can lead to

How data can improve fleet safety and efficiency

In commercial trucking you can’t leave anything up to chance. You need your fleet operating safely and at peak efficiency, always. More than ever, heavy-duty vehicles are using integrated technologies to collect data that can provide key insights to improve safety, efficiency and overall vehicle health. Now that tractors and trailers are online and collecting

Wheel hub locking nut tips for conventional, spacer setups

In a typical HD wheel hub assembly, the locking nut is used to hold assembly together and also set the bearing end play (for conventional setups). There are many types of lock nuts in use. The most common ones include:• Conventional Dowel Type (Double Nut)• Single nut with separate keeper (Ex: Stemco’s Protorq)• Integrated design

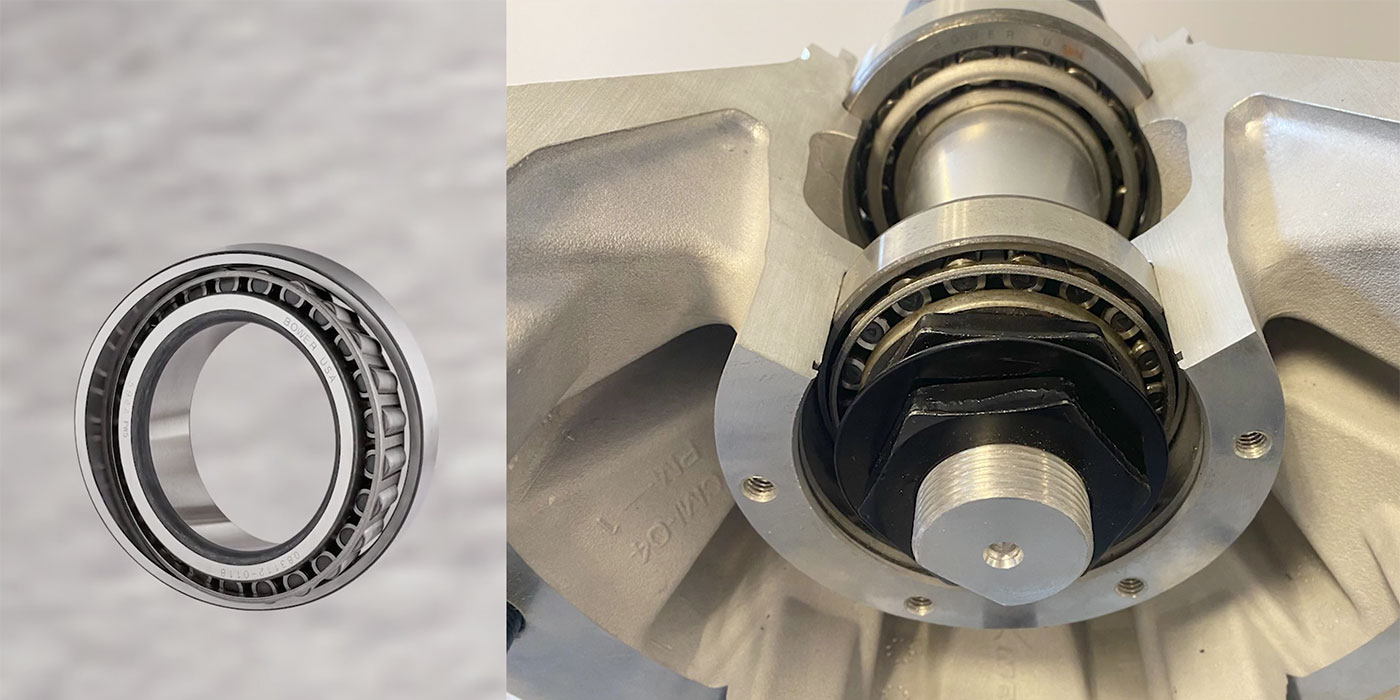

What you need to know about pre-adjusted wheel bearing

For the Heavy Duty truck market, there is an option to use pre-adjusted wheel bearing sets with spacers or conventional wheel bearing sets. Pre-Adjusted sets are typically used with a spacer setup. We get the question “Can a technician use a conventional bearing set with a spacer in place of a pre-adjusted set”. Short answer

Telematics solutions that can tell you if your truck has a service problem

Do I have a service problem? Whenever a fault code is triggered or a telematics alert goes out, it’s one of the first questions fleet managers have. Telematics systems are evolving to present information more actionable—providing guidance in the form of prescriptive maintenance—as opposed to alerts that don’t give you much direction. The onus of

What fleets need to know about truck brake, wheel end service

While a comprehensive maintenance program is always essential for the performance of key heavy-duty truck brake and wheel end systems, it can be even more critical when fleets adopt new and different types of components and technologies. “Regulatory changes, such as those requiring copper-free brake pads, may influence maintenance intervals for brake components,” says Jeff

Bendix offers tips to extend disc brake pad, rotor life

This Tech Tip, provided by Bendix, series addresses actions that fleets and owner-operators can take to protect that investment and extend the life of their air disc brake (ADB) pads and rotors. “The more people realize the benefits of air disc brakes, the more we want to help them maximize ADB advantages over the life

SKF global transportation business updates name to SKF Vehicle Aftermarket

SKF announced that it will now refer to its global transportation business unit as SKF Vehicle Aftermarket. The company says that the business unit, formally known as SKF Vehicle Service Market, will continue to offer premium wheel end components and other related parts and services to aftermarket distributors, installers and customers. To reflect the new