Wheel bearings may not be the first item you think of when making your fleet’s maintenance checklist. There are bigger components—the engine, the tires, the safety system—that, just by their nature, demand more of your attention.

But that does not mean that wheel bearings can be swept under the rug, as failures can lead to serious consequences, some even as severe as the truck’s wheel flying off while driving.

So, with that in mind, these are the eight most common potential wheel bearing issues, and how to spot them.

1. Bearing set too tight

Wheel bearings should be set between 1 and 5/1000s of an inch (0.001-in. to 0.005-in.), and ideally in the middle of those two numbers.

“If it’s tighter than one thousand,you’re running very close to preload,” explains Divjot Singh, Application Engineer at NTN. “Imagine the lubrication getting squished out below the rollers. If there’s no lubrication layer, there will be metal on metal contact creating heat, which leads to flaking.

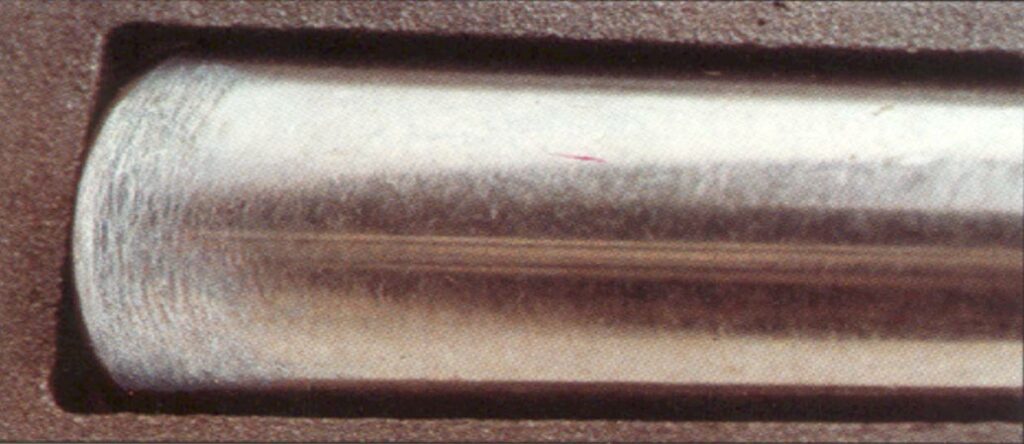

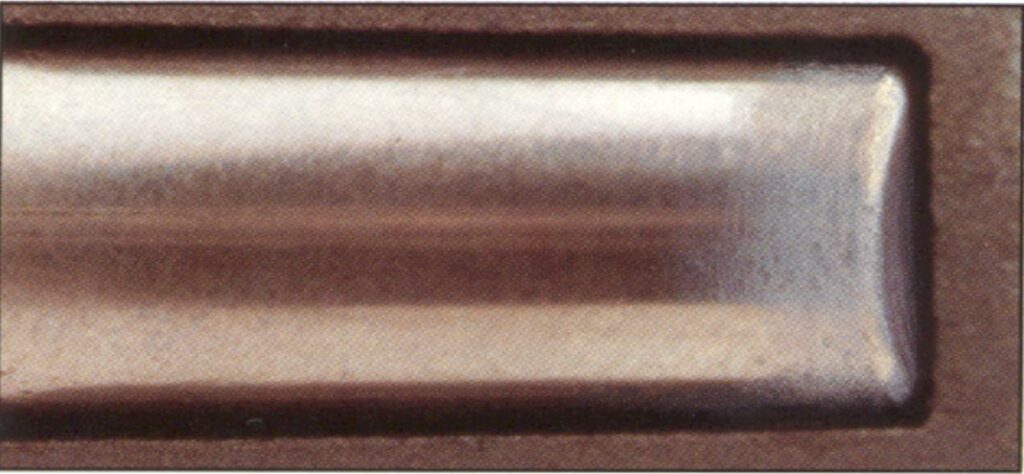

“The way to tell that it’s a high preload is that you will see wear on the large side of the roller,” he continues. “So, the rollers are tapered—imagine if you were to take a cross section: The top would be smaller, the bottom would be larger. And the wear, if it’s more on the bottom on the large side, that’s how you can tell that it’s from a high preload setting.”

The indication of an improperly set bearing comes from a noise the driver will hear on the road.

After hearing this noise, Singh says what technicians will do is isolate which side of the truck, or which axle, it’s coming from.

“Once they narrow that down,” he continues, “then they will actually inspect that side and then take the wheel end apart.. That’s when you will see this actual flaking. But, without actually taking the bearing out, you cannot see or you cannot tell how much damage has already happened.”

2. Bearing set too loose

This, Singh says, is more common than the bearing being set too tight.

“Typically what happens is, over time, bearing setting will become loose because there’s wear and tear,” he explains. “And, if the initial setting was too loose to begin with, the more wear and tear happens, the looser it is going to get eventually. So, as you can imagine, if it’s too loose, there’s going to be a lot of excess play and vibration in the system. This could lead to a multitude of issues not limited to wheel wobble, seal leakage, ABS and braking problems. Eventually a too loose setting will cause flaking at the small end of the rollers/races leading to failure. If damage is severe, it could even lead to the wheel coming off.”

The indications are similar in each case, Singh says, but you won’t know whether the bearing is too tight or too loose until the technician opens it up to have a look.

A loose bearing, specifically, is what can lead to the wheel coming off while the truck is being driven—thus, the consequences can be severe both from a road safety perspective and also from a fleet liability perspective.

The bearing being set too loose or too tight are the most common potential failures, but it’s worth quickly running through the others as well.

3. Bearing overload

Overloading isn’t common and tends to be specific to certain applications—in the garbage truck segment, for instance. Sometimes you’ll see flaking across the entire raceway—it’s not towards the left or to the right, so it’s not from an improper setting, but from overloading.

4. Misalignment

Misalignment occurs when the bearings are not seated properly. Improperly seated bearings will still function, but they will not have the full life of a typical bearing. That said, Singh says that this is not a common issue; however, it is possible.

5. Contamination

If the bearing has collected a significant amount of dust before installation, it can stick to the rust preventative substance on the bearing and this could lead to contamination.

“While installing, we tell the techs to make sure everything is clean, keep the bearings and all the parts in the boxes until you’re ready to work on it,” Singh recommends.

6. Improper Lubrication

“Contamination could also come from faulty lubrication,” Singh continues. “So, if the lubrication is not clean or if they did not properly flush the old one out, it could be from that, too.”

7. Impact Loads

This is a potential issue that can happen during installation. It’s not very common, as Singh notes, but possible if technicians do not use the proper pressing tools.

8. Fretting Damage

Fretting corrosion has a rusty appearance and can occur when the race spins or creeps inside of the hub—but, Singh notes, this is not very common at all.

Maintenance frequency

The answer to avoiding these issues is a simple one: Make sure wheel bearings are part of your fleet’s regular maintenance schedule.

How frequently that happens, like all maintenance, depends on your application or schedule. Trucks in the refuse applications, for example, tend to need more frequent bearing replacements than their over-the-road counterparts, because of the wide variations in weights from the constant loading and unloading.

There’s no specifically correct interval—but, for instance, when the brakes are being checked makes for a good time to check the wheel bearings as well since the necessary components are being removed anyway.

This article was sponsored by Bower Heavy Duty Bearings by NTN. For more than 100 years, Bower Heavy Duty Bearings have earned a reputation for reliability and performance in the no-nonsense world of big rigs and other hard-working vehicles. Learn more about Bower at PowerofBower.com.