Wheel bearings are an important part of the braking mechanism. Let’s take a look at what makes them so important, and what fleet managers need to know.

Bearing basics

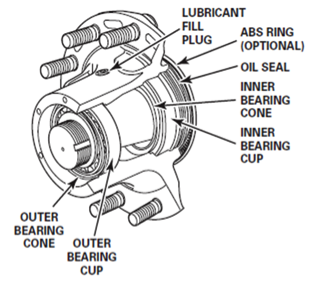

Divjot Singh, aftermarket application engineer for NTN, provided a walkthrough of the components of the wheel hub and how they all work together. These are the components of a typical wheel hub cross section:

Inner Bearing – Bearing set closest to the engine. Generally the larger of the bearings.

Outer Bearing – Bearing set closest to the end of the spindle. Generally the smaller of the bearings.

Locknut – Used to hold assembly together and set the bearing clearance.

Wheel seal – Also known as the oil seal. Mounted on the inboard side.

ABS Ring (optional) – Mounted on the inboard side of the hub.

“Bearings, seals, hubs, hubcaps, and adjusting nuts all work together for the performance of your fleet,” said Dan Humphrey, national sales manager for the commercial vehicle aftermarket with Timken. “Using quality components throughout your wheel end helps ensure trouble-free operations. With reliable, precise products demonstrating consistent performance, you gain more uptime.”

Making the right choices

“When specifying replacement bearings for commercial vehicle wheel ends, fleet managers must first identify the type of wheel end to determine if they have a manual or pre-adjusted wheel end configuration,” Timken’s Humphrey said. “This is critical because different bearings are required for each configuration to ensure proper setting.

“Secondly, it is important to replace the cup and cone together from the same manufacturer to ensure optimal performance.

“Finally, consider cost per mile when selecting replacement bearings,” Humphrey added. “Utilizing quality bearings and proper installation will maximize fleet performance.”

“Always procure case-carburized product over through hardened product,” NTN’s Singh advised. “Case-carburization is a heat treat process during which hard steel ‘case’ is formed on the rolling surfaces, leaving the inner core relatively softer. The softer core acts like a shock absorber and takes the brunt of the impact, thereby preventing catastrophic failure. All Bower heavy-duty bearings by NTN are case-carburized.

“Always purchase and install bearings in sets; i.e., cups [races] and cone assemblies [bearings],” Singh continued. “Sometimes it may be difficult to remove the old race from the hub and the technician may decide not to remove it. Although the old race may visually look okay, there is fatigue built up beneath the raceway surface, and the race may be only a few hundred miles from failure.”

The fuel efficiency factor

Fleet managers are no strangers to the constant hunt for fuel efficiency gains. What some might find surprising, though, is that wheel bearings are one truck component that can help in this quest.

“There have been engineering and manufacturing enhancements that allow for fuel efficiency,” Timken’s Humphrey said. “Timken manufactures fuel-efficient bearings by optimizing internal geometry and surface finish on bearing components to reduce rolling torque.”

“Crowning the rolling surfaces helps distributes load better and also reduces edge stresses, thereby increasing efficiency,” noted NTN’s Singh. “Other ways to increase efficiency include improving the surface finish of the rolling surfaces, and incorporating sphering [on the rollers], which reduces friction. Bearing manufacturers such as NTN have dedicated design groups working relentlessly to keep improving these features.”