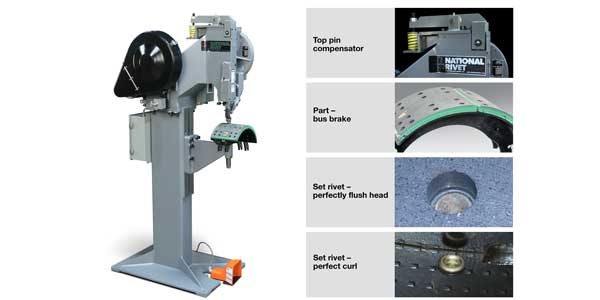

National Rivet and Manufacturing Co. highlights its Model 800 and Model 1000 rivet setter featuring a top-pin compensator, a solution for cracked brake linings. The compensator provides consistent rivet sets and nearly eliminates cracked brake lining issues by counteracting for variable work thickness up to plus or minus (+/-) 1/16 in., the company says.

“We designed the top-pin compensator with the brake shoe industry in mind, and especially for truck and bus applications,” says Kevin Klapperich, manager of the machine division for National Rivet. He explains that the brake lining manufacturing process can yield counterbores with slightly varying depths. With a thicker counterbore, the stroke of a standard machine could crack the linings, while a slightly undersized counterbore might result in a loose rivet. While such occurrences are infrequent, they happen often enough to interrupt workflow and add unnecessary costs.

These machines have been specified for a variety of applications ranging from computer frames to automotive components, National Rivet says, adding that it now uses the top pin compensator almost exclusively on electromechanical riveters used for brake applications.

“When accuracy is needed for successful brake assembly, manufacturers can rely on the consistent quality of the Nation Rivet Model 800 and 1000 units with top pin compensator,” says Klapperich. “These electromechanical riveters offer a cycle time of 1/3 of a second, so an experienced machine operator can rivet a brake shoe faster than with a dual hydraulic machine.”

For more information, visit the National Rivet website.