As a highly efficient power source for propelling electric vehicles, truck e-axles must be designed to go beyond providing torque and power to also balance performance, durability and reliability with maximum time on the road per charge. That’s according to Steve Slesinski, director of global product planning for Dana.

“E-axles have continued to advance in terms of their overall simplicity as well as the level of power density, reduced packaging size and weight, lower noise emissions and increased system efficiency,” Slesinski says. “Improved design flexibility for battery placement and truck body positioning and reliable performance and robustness also continue to be a key focus of their development.”

Alex Schey, chief commercial officer for electrification at Allison Transmission, points out that the development of e-axles is helping spur the market entry of higher performing and more efficient electric vehicles. “The combination of improved packaging and lower weight also supports OEMs who need to employ large battery packs without compromising on cargo space or load capacity,” he says. “Newer e-axles can utilize fully integrated electric motors, improving performance, efficiency and cooling while reducing the impact on packaging flexibility.”

E-axle progress is now very rapid, relates Pedro Garcia, director of advanced technologies at Meritor. “The power ranges, flexibility and modularity of e-axles is significant,” he says. “Using several design levers, including different motor power and transmission options and available gearing combinations, e-axles can be configured to meet and exceed performance targets for virtually any Class 5 to 8 vehicle application.”

Meeting e-axle maintenance needs

The manufacturers of e-axles are also focused on maintenance needs for their newest technologies. Primary training will be similar across most EV systems, Allison’s Schey notes, adding that the most important topic is high voltage safety. “The majority of heavy-duty EVs operate at 650V nominal, with peaks up to 800V, so certain precautions have to be taken to safely service the vehicle,” he explains. “However, much of the e-axle will be familiar to technicians, with brakes, suspensions and wheel ends all being common with conventional axles.”

Pedro Garcia at Meritor says that while technicians will need to understand high voltage systems and safety, manufacturers are already well down the path toward providing training. “Overall maintenance requirements are inherently lower for electric drive systems when compared to diesel powertrains,” he adds, “as there is a reduction in overall systems and parts.”

Just like maintenance for conventional vehicles, fleets should always follow the OEM’s recommended practices for EVs, Dana’s Slesinski points out. In addition, key safety and maintenance topics for electrified vehicles should include the fundamentals of an electrified system and its components, including architecture, charging and high-voltage considerations; pre-operation inspections; EV maintenance schedules; and guidelines on servicing a vehicle after impact or water submersion. There are also high-voltage caution, personal protective equipment, primary shutdown methods and damaged battery handling procedures to be covered.

Expanding e-axle product lines

The current portfolio of Spicer Electrified e-axles covers Class 3 through 8 truck as well as bus applications. Included are the eS4500i, eS9000r, eS6200r, eS5700r, eS13.0xr and eS19.0xr models. In particular, the new eS6200r will be available for hybrid applications on long-haul vehicles this year. Additionally, the Dana Spicer Electrified S190 is part of the Hyliion Class 8 hybrid solution, which has been running on fleet vehicles in North America since 2019.

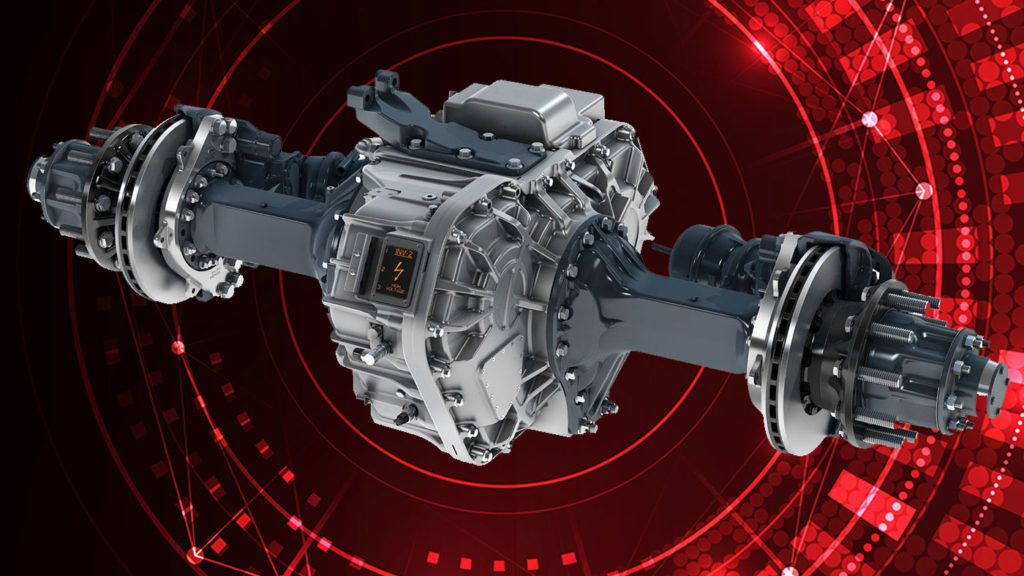

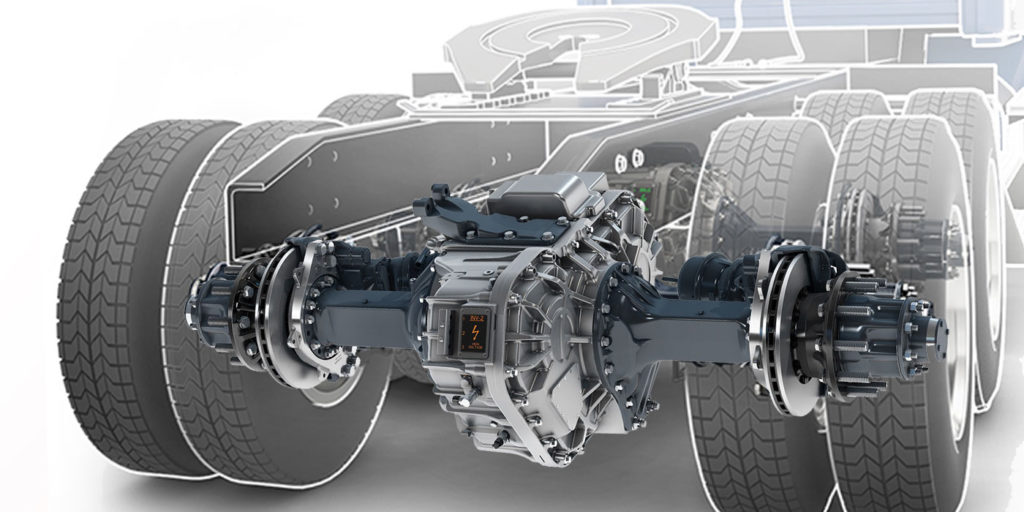

Meritor is moving to series production of e-axles later this year. The company’s line of all-electric powertrains for Class 5 to 8 vehicles includes the 12Xe, 14Xe and17Xe models. In the 14Xe that is going into production in 2021, the same 14X axle housing uses existing frame and suspension mounting hardware for ease of OEM integration. At the same time, a modular system approach enables the interchangeability of motors, transmissions, gearing, brakes, wheel ends and housings.

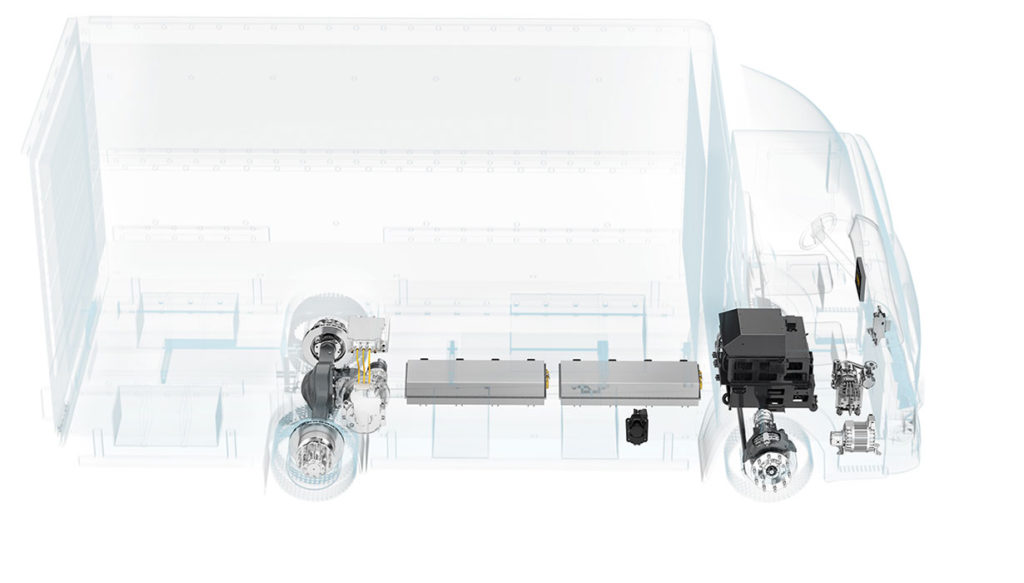

Allison is currently in the market with its eGen Flex EV electric hybrid propulsion system as well as the eGen Power 100D, a 23,000-lb. rated dual motor e-axle capable of outputting 400kW of continuous and 550kW of peak power for Class 8 models. The company’s eGen Power technology is designed as a bolt-in solution compatible with current frames, suspensions and wheel ends. It features fully integrated electric motors, a multi-speed gearbox, oil cooler and pump, and is designed to work in full battery electric and fuel cell electric vehicles as well as range extending hybrid applications.