Specifying wide-base single tires is helping Con-way Truckload offset fuel economy losses and keep costs in check

With the acquisition of Contract Freighters Inc. (CFI) behind it, Con-way Inc. has set out to take advantage of the expertise and capabilities of both companies. Today, the combination of the resources of CFI and Con-way Truckload has expanded the North American operation and provided new opportunities to provide customers with more comprehensive services. It also has meant a continuation of the pioneering traditions that have made the company one of the best managed in the industry.

Based in Joplin, Mo., Con-way Truckload provides a variety of dry van, specialized and intermodal services. The fleet of 2,700 tractors and 8,000 trailers operates across the continent transporting general commodities from five dedicated truckload terminals, as well as Con-way’s network of more than 460 operating locations throughout the U.S., Canada and Mexico.

Operating well over 500 million miles per year, notes Bruce Stockton, vice president of maintenance, means that even the slightest increase in cost per mile can add up quickly. Not surprisingly, one area that the fleet is addressing closely is fuel costs.

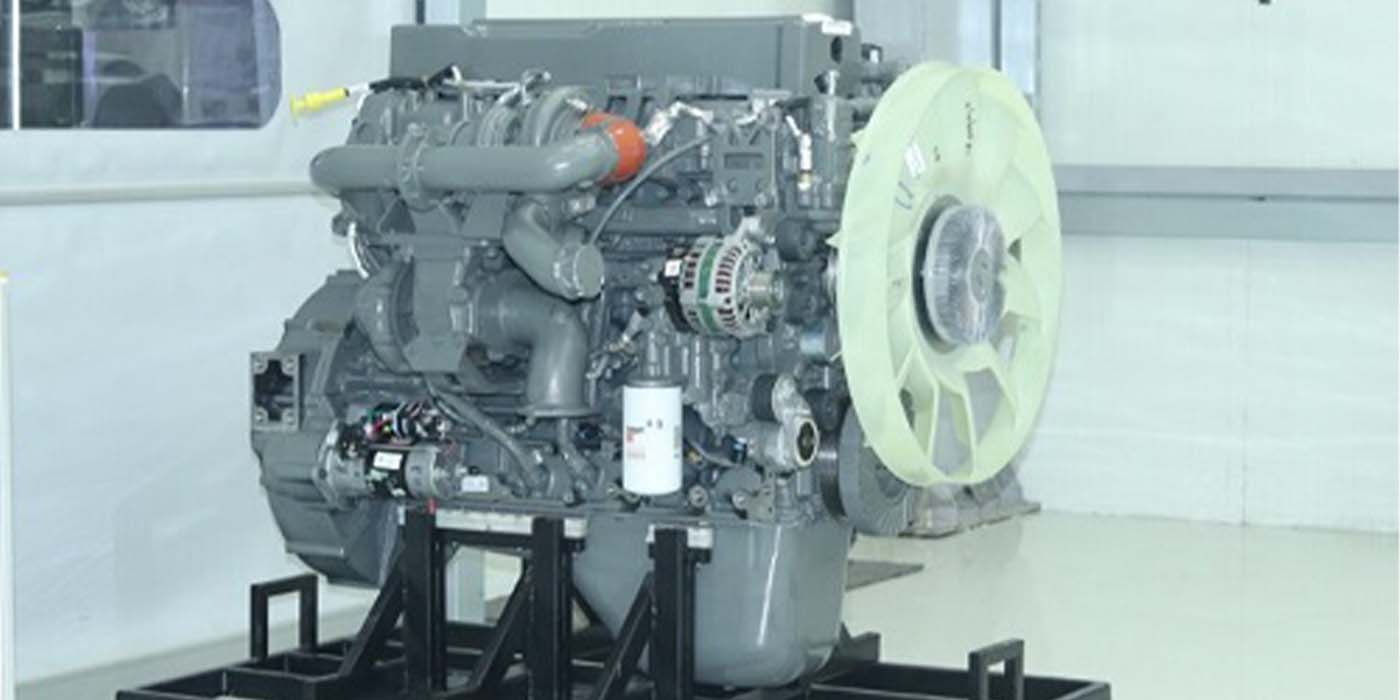

“When 2002 emissions-compliant engines were introduced we initially held off buying them,” Stockton says. “We did purchase some used trucks that were spec’d close to our standards, but with different transmissions and rear axle ratios we saw a drop in fuel efficiency. It was at that time that we decided to try some wide-base single tires and see if the manufacturer’s fuel economy claims were true.”

Fuel saving advantage

After fitting the trucks with Michelin X One wide-base single drive tires, Stockton reports, it was soon clear that claims of better fuel economy from lower rolling resistance compared to dual tires were accurate. ”The tires made up the difference in fuel efficiency,” he states, “so when we started buying new trucks in 2004 we made the X One tires a standard specification. There was no additional cost for the tires and we gained an average of 2/10ths MPG, which offset the fuel efficiency loss of the newer engines.”

Stockton notes that the wide-base single tires gave Con-way Truckload an advantage because the fleet did not have to absorb costs associated with lower fuel efficiency, and that today those savings have continued. Having converted its entire fleet of tractors to wide-base singles, the fleet is now changing trailers over to the Michelin X One tires and is seeing an additional 2/10ths MPG savings per combination.

“We’ve been operating some 2007 engines for about four months,” Stockton explains further, ”and those powerplants, in combination with the use of Ultra Low Sulfur Diesel, get about 2/10ths MPG less than our 2002 engines. With the wide-base tires on trailers, though, we’re gaining the loss back with the wide-base tires. Essentially, the X One tires are helping us hold our ground against fuel economy losses.”

Stockton is also quick to point out that Con-way Truckload has had fewer tire related breakdowns with the Michelin X One tires, something he attributes to the tire’s Infini-Coil Technology. The design, he explains, wraps a quarter-of-a-mile of steel cord around the tire, allowing it to maintain a constant footprint for even tread wear, and deliver the necessary traction and control. The elimination of two sidewalls by replacing dual tires, he adds, also reduces potential failure points.

Con-way Truckload also has not had any problems finding replacement tires on the road. In addition, the fleet is now using X One wide base retreads on trailers. The mold cure recaps have been supplied by Michelin Retread Technologies in Duncan, S.C. Plans are also underway to begin using pre-cure retreads built by local Michelin dealers.

Overall effort

The use of wide-base single tires on Con-way Truckload vehicles is part of an overall effort by the company to find ways to reduce emissions and fuel consumption. Among other actions taken are practices aimed at reducing idling, including equipping trucks with auxiliary bunk heaters, designating no-idle zones at terminals and increasing the number of team drivers in the operation.

“Reducing emissions is a good thing but it also creates a need to stay on top of fuel economy losses that result from things like new engine technology,” Stockton states. “Another result is that we have to consider weight issues because the new engines are heavier. For example, we now specify a 13,200-lb. capacity steer axle in place of a 12,000-lb. model and use Michelin XZA-3 H rated steer tires because they have a 16-ply design to handle the heavier front axle loads.

“In 2006, before buying new 2007 engines,” Stockton continues, “we assembled a group of drivers and technicians to discuss how we could take weight out of vehicles by eliminating items we could do without. They produced a long list of items and our drivers made the final choices. In addition to the 400 lbs. we saved by specifying wide-base tires, we were able to cut 673 lbs. from the tractors.”

A large part of that weight savings came from reducing fuel tank sizes from 120 to 100 gal. Data revealed that the average fill was 80 gal. per tank, Stockton notes, so a 100-gal. capacity did not mean extra fuel stops. The result, a smaller tank and 40 fewer gallons when full, cut tractor weight by 376 lbs.

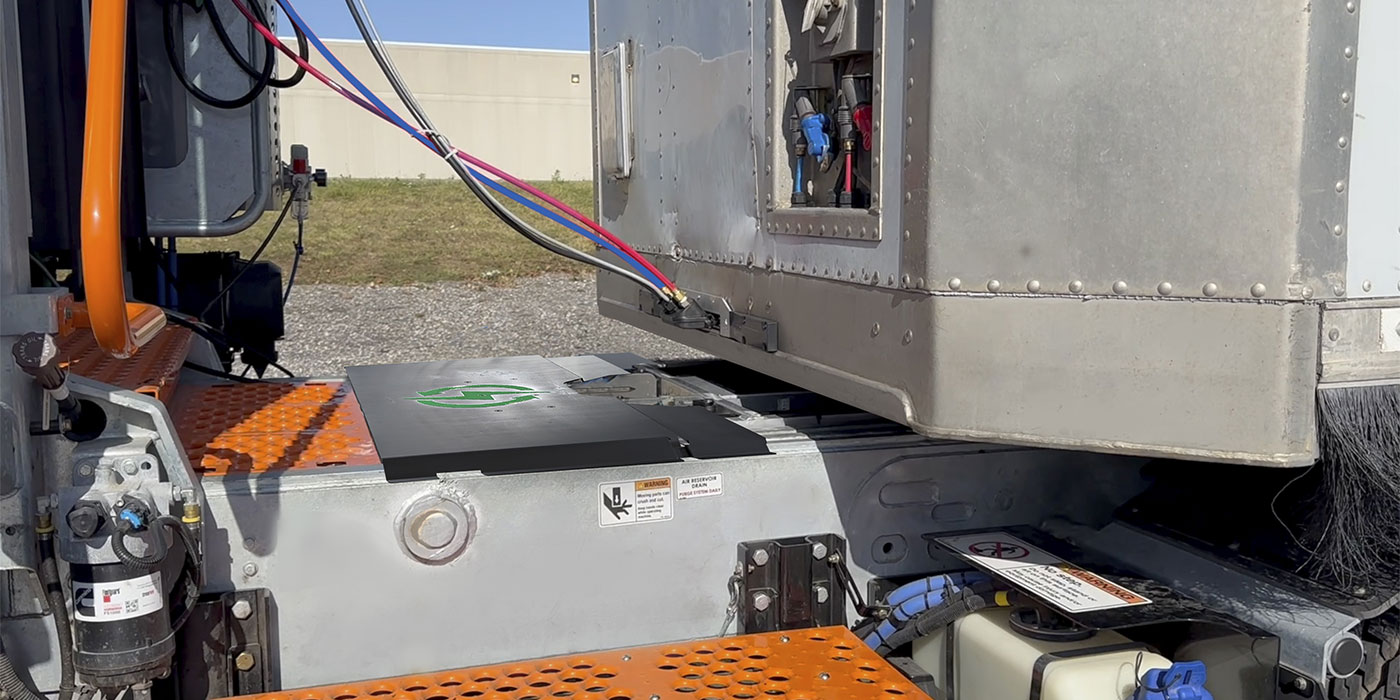

Other sources of weight savings on Con-way Truckload’s newest tractors have come from eliminating deck plates and lowering trailer glad hand connections so they can be reached from the ground. Additionally, a shorter wheelbase meant less frame weight, a change to horizontal exhaust systems cut

80 lbs., PACCAR AG380 air ride suspension systems shed 53 lbs., and eliminating quarter fenders cut an extra 55 lbs.

The tractors now in the Con-way Truckload fleet include Kenworth T600s for single drivers and T2000 and T660 power units, the latter equipped with Studio Sleepers for teams. In addition, a group of 300 Freightliner Cascadia models have been ordered and are now being delivered. Trailers include about 3,000 newer Wabash 53-ft. aluminum and composite plate models as well as Monon, Great Dane and RSI dry vans.

Streamlining maintenance

Typically traded after about 48 months and 500,000 miles of service, Con-way Truckload’s tractors are as standardized as possible to streamline maintenance needs.

From 1993 to 2000, all maintenance and repair work on the fleet was outsourced. Today, about half of all service is performed by a staff of about 100 people in the company’s tractor, trailer and body shops in Joplin and in a trailer maintenance facility in Laredo, Texas.

“While we’ve spent eight years developing and building our in-house maintenance operation,” Stockton says, “we also use the Kenworth dealer network, including the MHC Group of 40 dealers. “They have been our premier vendors for parts and service for many years, and we believe that loyalty should work in both directions.”

One change that Con-way Truckload has made recently was to add new Freightliner Cascadia tractors to its fleet. “We’ve grown very impressed with how Freightliner has paid attention to our needs, and in how they consulted with drivers and buyers to make this truck right inside and out,” Stockton states. “They’ve stepped up so we wanted to give them a try.”

Having first joined CFI in 1985, Bruce Stockton spent 13 years in safety, claims, risk management, driver recruiting and training roles for the company. After two years as vice president of operations, in 2000 he assumed his current role as vice president of maintenance.

“My experience in other areas of the operation has helped me in this role in many ways,” Stockton says, “but in the 23 years I’ve been with this company, the past eight have definitely been the most challenging and the most exciting. We may have a new name on our fleet, but Con-way Truckload still has the same pioneering spirit that has led to success for more than 50 years.”

About Con-way Truckload

The Con-way Inc. acquisition of Contract Freighters Inc., a company founded in 1951 with a single tractor and two trailers, established a unique enterprise in the freight transportation industry, offering less-than-truckload (LTL), truckload (TL) and supply chain management services in North America and around the world. Today,

Con-way Truckload boasts the most direct delivery points in the U.S. and Canada. In addition, since 1985 its CFI de Mexico subsidiary has offered trailer service at various border crossings through interline agreements with Mexican carriers. The operation, one of the first carriers to enter Mexico, has received the President’s E and E-Star Awards for excellence in export service.

Con-way Truckload Trailer Specifications

Model: Wabash; plate

Length: 53 ft.

Landing Gear: Jost

Axles & Suspension: Hendrickson

Oil Seals: Eaton Outrunner NOK

Tires: Michelin X One, wide-base single

Lighting & Electrical: Truck-Lite, Grote\\

Con-way Truckload Tractor Specifications

Models: Kenworth T600, T2000, T660; Freightliner Cascadia

Wheelbase: 224 in. on T600, T2000 and Cascadia models; 238 in. on T660s

Engines: Caterpillar C15; Cummins ISX

Clutch: Eaton Fuller Solo

Transmission: Eaton Fuller, 13-speed

Front Axle & Suspension: Spicer, 13,200-lb.

Power Steering: Sheppard

Rear Axle: Spicer, 46,000-lb.

Wheel Seals: Eaton Outrunner NOK

Wheels: Alcoa DuraBright, aluminum; wide base drive

Tires: Michelin X One drive, XZA-3 steer

Fifth Wheel: Holland

Fan Clutch: Horton

Lighting: Truck-Lite, Grote

Seats: National

Fuel Tanks: dual, 100-gal.

Paint: Dupont Base/Clear 600