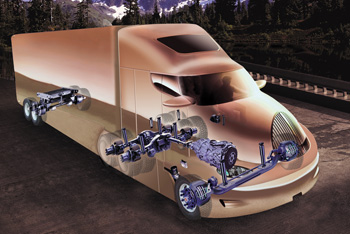

How does a tractor’s drivetrain impact vehicle fuel efficiency? How do engine specifications affect the choices that fleets make for fuel-efficient drivetrain components? How do tires affect these choices? Are there other considerations fleet managers should have when spec’ing drivetrains for maximum fuel efficiency?

“Take into account the entire vehicle, not just individual components,” says Jim Whirt, regional sales manager-Southeast at ArvinMeritor. “A drivetrain is part of the total package, in which everything works in concert. Vehicle design, payload, the truck’s route and even the driver are all considerations.”

“The drivetrain plays a significant role in specifying an overall fuel-optimized vehicle package,” says Mark Boardman, senior chief engineer-powertrain integration at Eaton Corp. “Drivetrain specifications are very dependent on factors such as engines, drivers, loads, routes and even speed limits.”

Primary factor

For ArvinMeritor’s Whirt, the loads being carried are a primary factor in drivetrain specifications. “The optimum transmission, overdrive or direct drive, the proper rear axle ratio to match the engine and transmission, and even the amount of flex in the suspension are important,” he says. “The load, whether it’s heavy or light, drives everything. For example, a heavy driveline may not be needed or the transmission or axle spec’s could change.”

“Most highway fleet vehicles spend 85% or more of their operating time in the top gear of the transmission,” states Eaton’s Boardman. “That means over 90% of the fuel used is burned in top gear. Focusing drivetrain efficiency on that area, where it is the most effective, means improving the bottom line for long haul fleets.”

Gaining attention

For some highway fleet operations, Boardman notes, utilizing a direct-drive transmission can improve the top gear fuel efficiency by one to two percent. The direct drive is not for everybody, he acknowledges, but with high fuel prices, reductions in cruise speed and availability of faster axle ratios, this drivetrain specification is gaining attention.

“Another drivetrain efficiency opportunity is in single drive axles,” Boardman continues. “For some operations there is a fuel efficiency benefit from removing the parasitic loss of a second drive axle.”

Optimal operation

Properly specified drivetrain components also ensure that the engine operates at its optimal speed for a given operation. “If you change an engine, it changes the entire fuel and power curve,” explains Arvin-Meritor’s Whirt. “It alters the final gear ratio, which not only changes speed parameters but also impacts fuel efficiency. Start with the engine and other spec’s will follow. For example, driveline spec’s are based in part on engine torque and demand because you have to worry about startability and gradeability.”

Typically, relates Eaton’s Boardman, the drivetrain is specified to optimize the engine, but in some cases, the engine can be specified to optimize the drivetrain. “Many engines today are designed to offer multiple torque ratings,” he explains further. “Higher torque levels in the top gear of the transmission mean better ability to maintain road speed, reducing the opportunity to inappropriately select a lower gear. Raised engine torque increases the time spent in top gear, but the multi-torque feature must be used along with a fuel-efficient road speed limit to realize the full benefit of keeping the engine at the optimal RPM.”

Impacting drag

The impact of drag from drivetrain components on fuel consumption is actually low compared to the energy required to overcome other elements such as tire rolling resistance. “Tire tread patterns can greatly impact rolling resistance,” says Arvin-Meritor’s Whirt. “Also, when fleets are looking at total vehicle efficiency, changes in tires, including sizes, might mean the need to change the selection made for drive axles.”

Tire specifications can be used either to fine-tune the engine’s operating speed or improve an existing drivetrain specification, says Eaton’s Boardman. “There are only so many axle ratios to choose from,” he states, “and those that are available are adequate for most drivetrain specifications. A tire size change of 10 revolutions per mile calculates to about a 2% change in engine RPM. Assuming the cruise speed stays the same, a 10 revolution per mile increase in tire size will reduce engine speed at cruise from 1,400 to 1,375 RPM.”

Other opportunities

There are other opportunities to consider that can increase the mechanical efficiency of drivetrain components, the manufacturers note. For example, says ArvinMeritor’s Whirt, synthetic gear lubricants play a role in efficiency because they are more slippery and more stable, which reduces parasitic losses within the components.

“Today,” adds Eaton’s Boardman, “many transmissions are designed for synthetic lubricants with special processing on gear tooth surfaces that takes advantage of the properties in synthetic lubricants by maintaining oil film under extreme loads.”

New level of optimization

Yet another opportunity to improve drivetrain efficiency is being found in the integration between the engine, transmission and other components. “The ability of drivetrain components to communicate with each other through data links means drivetrain components can interact and adjust to specific operating conditions,” says Eaton’s Boardman. “Advancements in electronics are blazing the trail for an entirely new level of drivetrain optimization.”

New, more efficient components and drivetrain concepts––including some that are radically different than those in use today––are already under development. By being firmly focused on fuel economy, the manufacturers say that in the future fleets can expect technological developments that will enhance the fuel efficiency of each drivetrain component and the systems as a whole. FE