“It all depends on what you want to do with it!” is what you hear when asking for advice on writing spec’s for a tractor. Spec’s that are right for you may not work well for the fleet down the street and vice versa. “Fleets look for performance and choose products that have provided superior performance in the past,” says Charlie Allen, director of global customer service for ArvinMeritor. The two subject components––suspensions and drive axles––are good examples of items that might get carried over from a previous spec’ sheet without additional analysis.

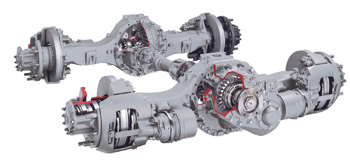

Drive axles

When purchasing new vehicles, don’t miss the opportunity to put together a spec’ sheet that results in the purchase of trucks offering you the greatest efficiency and highest durability. “For proper component specification, dealers and OEs must know the truck’s purpose and application including desired road speeds, engine torque, tire sizes, road conditions and routes. Use the engine manufacturer’s software to specify a fuel-efficient drive train. Vehicles should not be mixed in  applications. For example, a single-axle P&D truck can’t perform the same duties as a tandem-axle truck spec’ed to haul construction materials. Fleets can avoid frustration by using the right truck for the job,” says D. Mike Pennington, senior director of global marketing communications and industry relations at ArvinMeritor.

applications. For example, a single-axle P&D truck can’t perform the same duties as a tandem-axle truck spec’ed to haul construction materials. Fleets can avoid frustration by using the right truck for the job,” says D. Mike Pennington, senior director of global marketing communications and industry relations at ArvinMeritor.

Dana Spicer engineers tell us that correctly spec’ing a drive axle for the job to be done is an essential factor in preventing failures. It is extremely important to spec’ an axle of sufficient strength to work under the planned vehicle operational environment as well as the vehicle load rating. Operating a vehicle outside of the specification (i.e., overloading and/or operating under more demanding conditions) may increase torque requirements and could cause premature damage or failure of axle components. The drive axle must be designed with the strength capable of withstanding the punishment of a loaded truck in operation.

A vehicle is designed to do a certain job under certain conditions. More severe use of the vehicle, such as overloading or operating under adverse road conditions not considered when spec’ing the axle, is termed misuse or incorrect operation. Under severe misuse, parts could fail immediately. With lesser misuse, the parts could progressively fail over a period of time.

All components—ears, shafts, bearings and housing—must meet three essential requirements:

• Carry the load. In most instances, the drive axle supports the major portion of the truck and its payload.

• Withstand the stress of torque developed by the engine and multiplied by the drive train.

• Withstand the stress of impact and shock forces created by road conditions and vehicle operation.

To prevent axle overloading, the axle rating must be compatible with the weight specification of the vehicle, load and expected operating conditions.

New axle designs

Total vehicle weight has been an important consideration in many fleet operations and is becoming even more important with the additional weight being added to power units because of 2010 emissions regulations. As a result, suppliers are designing lighter-weight products. Dana Spicer, for example, has released two new bowl tag axles, the S21-060B and S23-070B, which can be combined with a heavy single drive axle to make a lightweight, efficient 6×2 tandem configuration. Such a configuration saves up to 400 lbs. over the company’s standard DS404 6×4 axle model. These tag axles have standard rear axle housings for easy installation as well as bolted covers and pressed-in spindle plugs for in-use flexibility and possible future conversion to an active drive axle.

Just as important as component weight is product efficiency, and without an awareness of new products, new, more efficient components might not be considered when new vehicles are being purchased. ArvinMeritor, for example, will be introducing a replacement for its widely used RT40-145 axle this spring. The new design, called the 14X, will have a fast, 2.47 ratio, improved operational and lubrication efficiency and other features considered by some to be more than standard. ArvinMeritor’s Allen says, “We believe that by incorporating features others consider to be premium, we don’t have to differentiate between standard and premium products. For example, our axles have induction-hardened spindles at both inner and outer bearing positions. Others don’t necessarily do that.” Improved efficiency can mean better fuel economy.

Suspensions

While the trucking industry is often slow to embrace new technology, air suspensions for rear axles were quickly adopted by the industry’s over-the-road segment. They are now standard for line-haul and growing in popularity in vocational fleets, as are front air suspensions. Dan Gadowski, director of chassis engineering at Daimler Trucks North America, says, “Today the line-haul truck market is dominated by air suspensions due to superior ride, handling and light weight—all of which come with solid reliability and low operating cost. Many operators also take advantage of the dump feature available with air suspensions during loading, unloading and coupling operations.”

Sean Coleman, director of sales and marketing for Hendrickson’s truck products, says, “We’re seeing a lot more single-axle tractors going to air suspensions––tractors in P&D and LTL operations. It’s rare to find these being built without air.”

It was decades ago when Neway introduced the first air suspension for the heavy-duty truck market. Just 20 years ago, the company launched its AD Series suspension, which became the benchmark for vocational air-ride. The company, now part of SAF-HOLLAND, is now bringing the Neway ADZ 123 to market. This will replace the AD Series. The new design takes out 220 lbs. per axle compared to a comparable AD model and also incorporates a number of features designed to improve the product’s durability, according to Mark Molitor, vice president of engineering, power vehicle systems business unit at SAF-HOLLAND.

Hendrickson’s Coleman tells us that his division has recently introduced the Primaax EX, which has been designed specifically for the demands of vocational, severe-service and heavy-haul applications. Primaax EX provides the same benefits as the manufacturer’s popular Primaax with additional features designed to increase durability, reliability and handling characteristics––up to 12.5 in. of diagonal wheel travel and eight inches of vertical axle travel. The product features a new frame hanger and torque rod configuration that provides increased roll stiffness and reduced roll steer for improved handling. Suspension-induced driveline vibration also has been reduced compared to competitive trailing-arm air suspensions.

Coleman describes a growing interest in front air suspensions. He says, “Since we introduced the Airtek, we’ve seen a rather rapid growth in the use of front air suspensions. Today, 10% to 15% of on-highway tractors are built with front air suspensions.” The Airtek offers both a good ride and performance along with 100 lbs. of weight reduction and reduced maintenance requirements. The design utilizes a Hendrickson-manufactured steer axle called Steertek, as does the company’s Softek system, which combines a Steertek axle and monoleaf spring technology to offer weight savings up to 92 lbs.

Maintenance

While spec’ing the right axle and suspension is critical, so is maintenance. Neither a truck’s suspension nor axle system demands extensive maintenance, but it will not tolerate complete neglect. Coleman says, “Fleets don’t want to touch the suspension. About the only thing we’ve seen that they will do on a regular basis is maintain the shock absorbers. Some fleets take care of that when they do an alignment, others as they change tires. That’s about the biggest maintenance item on air suspensions.”

SAF-HOLLAND’s Molitor says, “Check for tight fasteners. We recommend a first interval torque check for new vehicles after 1,000 to 5,000 miles of service. After that, it’s primarily bushing wear. We strongly recommend using factory service parts, which are made of premium rubber compounds.”

ArvinMeritor’s Allen says, “Start with our maintenance manuals. All of our documentation is available on our website through ‘Literature on Demand.’ Review the recommended service intervals and the lubricants we recommend. Lubricants are as important as the iron in the products we ship out of our plant doors. We’ve developed a material specification, and it’s important to use it.”

The correct spec’s for the application are critical, but more than hardware comes with the selection of a particular product. Never forget the field support that comes along with the brand selected. The major suspension manufacturers offer excellent aftermarket support as well as Internet- based information resources.