Over the last twelve to twenty-four months, it seems as though topics such as autonomous driving and ELD mandates have flooded the news headlines for the fleet transportation industry. And deservedly so, these are no doubt topical, important issues. However, in running your fleet day-to-day, understanding the evolution of maintenance and repair (M&R) issues and costs continue to be on top of the level of importance.

M&R is critical because it significantly impacts every type of operation and having improper management of M&R can drastically erode profits from the bottom line, and the older the truck, the costlier it gets. It is also the most volatile cost.

According to a recent report on lifecycle strategy, M&R costs on a 2015 sleeper model-year total $14,472, compared with $2,184 on a new, 2020 model-year truck, providing a savings of $12,288. Across a fleet of 100 tractors, this amounts to $1.2M!

A shorter lifecycle produces long-term savings beyond the first-year. When fleets adopt a three-year lifecycle for their trucks compared to a seven-year lifecycle, replacing with new technology in year four, they realize a savings of $42,830 in M&R calculated in years four through seven when compared to a fleet driving the same truck for the full seven years.

More Trucks Equal More M&R Challenges

More fleet managers are realizing these numbers, and they’re now placing a higher emphasis on M&R strategies. According to a recent survey, 40% of respondents listed M&R as their top motivating factor for acquiring new trucks. However, the survey shows that costs are not the only concern fleets have regarding maintenance; 26.7% also believe a safe, well-maintained truck is most beneficial in driver recruitment and retention – critical since the driver shortage remains a difficult issue for many transportation companies.

This issue will only grow in the coming years, as fleets look to either replace trucks or add to their mix to handle more demand for the economy. With the demand for shipping and transporting goods remaining healthy, and more trucks coming online, how can software and data analytics help fleets better manage M&R activities and spend?

Innovative Asset Management Analytics Focus On M&R Data

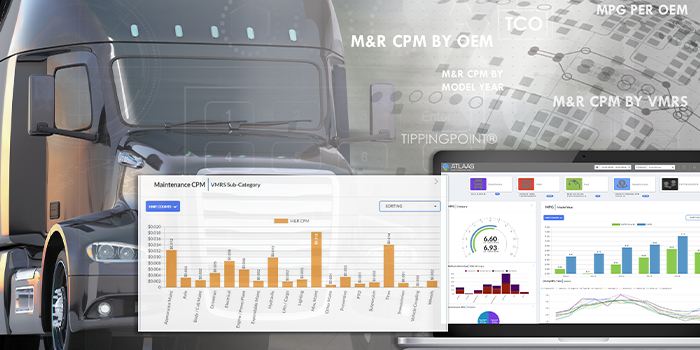

Today’s leading Asset Management software enables private fleets and for-hire carriers to leverage intuitive dashboards instead of complicated spreadsheets and allows users to create their own custom view with information most pertinent to their operation: vehicle performance and utilization, fuel economy, M&R data, exception and non-reporting units, and replacement vehicle savings, along with finance costs – providing a holistic picture of the total cost of operating the fleet.

What M&R Data Should Be Viewed?

When implementing an asset management platform to focus on M&R, the following data sets should be available from raw data:

- M&R Cost by VMRS codes and description

- M&R Cost by VMRS by subcategory

- M&R Cost by invoice average

- M&R CPM by location and model year

- M&R Cost by cab configuration

- Total M&R Cost by OEM and Model Year

- Maintenance servicing history per truck should also be accessible

- Preventative maintenance measures; brakes; expendable items; exhaust systems; fuel systems; and etc.

Easily monitoring these trends and managing these metrics will help to make more efficient, cost saving decisions and ultimately reduce your total cost of ownership.

Additionally, heavy-duty trucks must be well-maintained throughout the year and be prepared for all weather patterns. It’s important to take every precaution necessary, particularly with M&R to ensure the safety of drivers operating the trucks as well as other motorists on the roads. As such, it would be wise for fleets and for-hire carriers to pay particularly close attention to the latest software innovations that leverage fleet performance data and analytics to track all M&R activity to help ensure each truck is operating at a premium level. This will not only ensure safety for all on the road, it will significantly help the bottom line as well.

This article was sponsored by Fleet Advantage. For more information, please visit our website at www.fleetadvantage.com