Today, most passenger vehicles consist of numerous controllers that communicate with one another through something called Controller Area Network (CAN). In most modern vehicles, when you press on the brake pedal, the pedal position sensor data is transmitted through CAN to allow many controllers to make decisions at the same time. This not only applies the brakes, but also illuminates the brake lights, locks the seat belts, monitors individual wheel speeds in anticipation of a traction control or an anti-lock braking event, and much more. The same reaction also happens when you turn on your windshield wipers. This simple input from the driver is propagated via CAN to many different modules to not only start the wipers, but also inform them of the anticipated load on the vehicle electrical system, presence of water on the road, or even a maintenance notification indicating it’s time to replace your wipers.

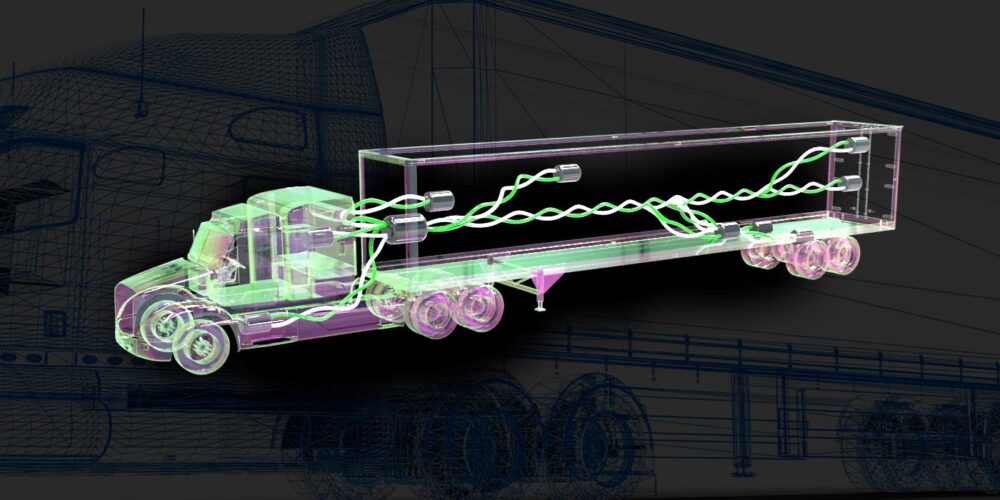

CAN takes hundreds of individual wires and whittles it down to two, known as a “twisted pair.” This pair creates a communication platform that runs the entire length of the vehicle, allowing each module to send and receive messages to and from all the other modules in the vehicle. It’s not only more efficient from a copper usage standpoint, but it also allows for significantly more information to be shared between modules, adding safety, efficiency, comfort, and other features to exist at a much lower cost.

European tractors and trailers have communicated with one another via CAN for more than a decade now. From this, fleets have experienced shorter stopping distances, enhanced driver situational awareness, an increase in safety, and a more complete driver experience due to the data that’s communicated throughout the entire vehicle. CAN has proven itself in this market as a viable and effective communication link between tractor and trailer.

Adoption of CAN in the North American trailer market has been slow because there simply wasn’t a whole lot you can do with it up to this point. The majority of trailers in North America only have a single ABS controller with the wheel-speed sensors directly wired to it. There’s no need for a communication BUS if there’s only one thing capable of talking. Furthermore, the J560 (seven-pin) connector that connects the tractor to the trailer doesn’t allow for CAN communication to cross from trailer to tractor.

With autonomous trucking on the horizon, CAN integration in North America is the next step in providing the autonomous truck the information it needs about its trailer–and in the time that it needs it.

“If you’ve got an autonomous truck going down the highway with a fireball behind it and there’s no driver, that’s a problem,” said Rob Phillips, chief executive officer, Phillips Industries, Phillips Connect. That’s why tractor-trailer communication is critical, and a key element in future-proofing your fleet. Phillips Connect and Phillips Industries, for example, work hand-in-hand with their integration partners to utilize CAN in trailers to create the same efficiencies for North American trailer owners that European trailer owners have taken advantage of for decades.

Where you’ll see this most readily is in the growing trailer telematics segment. It starts with choosing the right gateway, like the Phillips Connect Smart7 or StealthNet. The Smart7 is compatible with sensors via CAN, collecting billions of actionable data points and streaming them through the Connect1 user interface for fleet owners to analyze, track, and manage assets. Upgrading sensors to devices like CargoVision interior cargo camera is also beneficial, providing fleets with a volumetric view of every load and even indicating whether it’s safe to open the cargo doors. CAN will work at its peak if the technology is up-to-date, so enhancing your trucks with the latest technology is the first step to a more efficient fleet.

Dan Forthoffer is the corporate director of research and development with Phillips Industries and Phillips Connect.