In Class 8 on-highway vehicles, drivetrain specifications have a significant impact on fuel economy and on driveability, which leads to driver acceptance and retention. To help fleet managers take into account important factors when making drivetrain component choices, ArvinMeritor, Eaton and Dana offer a wealth of helpful advice.

For proper drivetrain component specification, know the truck’s purpose and application, including desired road speeds and routes. Be sure to understand that GVW and GCW ratings, cruise speeds, terrain, high grades and road surfaces, and duty cycle (long periods of constant speed driving or frequent stops and starts), all impact a drivetrain’s performance and service life.

In all cases, specify components that match the engine’s maximum torque, including higher torque if the engine will be re-rated for resale. Although the driver primarily controls engine torque, it is drivetrain specifications that control engine speed in any given condition, and affect fuel economy and performance.

A properly specified drivetrain will best keep engines operating at optimum fuel economy. Conversely, faulty drivetrain specification will result in engines operating excessively and not deliver good fuel economy. Less than expected component life can be avoided by specifying the right product for the right application.

Transmission choices

Specifications that should be considered include transmission overall gear ratio and transmission step size. Transmission overall gear ratio range should be selected to provide the required startability in the application, while still providing top end gear ratio for cruise speed operation.

The number of gears and step size should be selected to keep the engine operating in its best fuel efficiency area below cruise speeds. Engines with narrow fuel islands require smaller step size transmissions with more gears to get the best fuel economy, while engines with wider fuel islands use larger step transmissions with fewer gears.

An additional consideration is the use of transmissions with larger steps in lower gears and smaller steps in higher gears. The larger steps in lower gears have minimal impact on fuel economy since little time is spent in these gears, and smaller steps in higher gears allow for increased fuel economy in gears where the truck operates most of the time.

For many applications, use of a direct top geared transmission can be a simple, low cost alternative. That’s because gear and bearing frictional losses during top gear operation (typically 85% to 95% of running time for most linehaul trucks) is eliminated. That can result in fuel economy improvements of up to 1% or 2% versus a comparable overdrive specification.

Still, some limitations to the application of direct drives and potential fuel savings do exist, including:

• The limited availability of very “fast,” low numeric axle ratios may not allow for both high cruise speeds and very low engine speeds. Consequently, some vehicles may perform better with overdrive transmissions.

• Driveline torque increases by the percentage of one top gear step (typically 29% to 37%) for comparable direct versus overdrive transmissions. This can limit the use of higher rated engines, force driveline up-charges and increase shock load sensitivity.

• Some vehicles that operate in hilly and mountainous terrain have a low power to weight ratio. Others have average speeds limited by traffic congestion or variable speed limits. These vehicles may spend more running time in a gear one step below the top ratio, so an overdrive might yield better fuel economy than direct drive in this speed range.

Clutch impact

The clutch has little direct impact on fuel economy as it is mostly completely engaged when the vehicle is moving. However, newer engines operate at their best fuel economy at lower engine speeds, during which potentially harmful torsional oscillations may damage other drivetrain components. But the clutch can contain an internal element that dampens these oscillations to prevent damage. Drivetrain specifications designed to operate the engine at lower speeds for fuel economy should include a correct damper.

Clutch adjustment restores the designed clamp load to the clutch assembly and also restores the original angularity at the yoke tip/release bearing mating surfaces. Improper angularity can cause binding, increased pedal effort and possible early component wear.

Maximizing driveline life

Be sure drivelines are specified and maintained at the proper operating angles and for longer driveline life, adhere to proper applications and load ratings.

Using the proper lubricant and maintenance intervals will maximize driveline life. Lubricate u-joints and the slip section at the mileage or time intervals specified by the manufacturer, and lubricate only with an approved grease as specified or recommended by the manufacturer. Checking and adjusting driveline angles will also maximize the life of the driveline, as well as other drivetrain components.

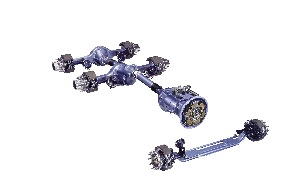

Axle considerations

Drive axle specifications dictate where the engine will operate during cruise conditions, and should be selected to allow for good fuel efficiency at the road speed and load where the vehicle will spend most of its time.

But trade-offs exist. Gearing the vehicle too fast may result in having to shift too often on slight grades. A good rule of thumb to follow is to gear the vehicle to allow it to pull a one percent grade in top gear at nominal load conditions.

Axle design (apart from ratio selection) may also impact fuel efficiency, especially with the use of a differential lube pump. Conventional differentials and lube pumps operate continuously and use energy. Some newer axle designs have on-demand lube pumps that only operate when needed, compensating for different wheel speeds to help conserve fuel.

Know the difference when specifying a Driver Controlled Diff Lock and Automatic Traction Control (ATC). A driver’s behind-the-wheel performance, including proper use of the vehicle’s inter-axle differential lock, driver controlled diff lock and ATC, can extend drivetrain life.

Evaluation

To best evaluate drivetrain component impact on fuel consumption, manufacturers use several SAE specified tests that are highly useful in determining relative fuel economy differences between vehicles and components. Manufacturers also perform extensive dynamometer testing to determine the efficiency of components.

Computer simulation is another important tool. These allow manufacturers to evaluate fuel economy much faster and more economically than field tests. Manufacturers also often work with fleets to monitor fuel efficiency and compare the results of different configurations in actual operation.

Drivetrain component suppliers are continually developing new products and features, as well as working to develop new solutions that will enhance fuel efficiency. A variety of advanced technologies and product enhancements are constantly under development.

Working within component suppliers’ application guidelines is recommended to determine the best vehicle specification for any application. In the end, the best results come from correctly specifying the drivetrain for the conditions under which it will operate.

Tech Tip: Synthetic Lubes

While synthetic lubricants cost more than non-synthetics, the net cost to fleets often becomes favorable over time, considering extended drain intervals allowed by component manufacturers. There also are some physical differences that make synthetic oils appealing. Synthetic lubricants are typically lower viscosity fluids. Use of lower viscosity fluids results in lower dynamic operating temperatures that in turn result in longer lubricant life.

More information at: www.arvinmeritor.com www.roadranger.com