The long, dark, cold hours of winter can put added stress on vehicle batteries and the electrical systems they support. Lighting and other power-hungry systems are used more frequently and for longer durations in order to keep drivers safe, comfortable and connected during the more frigid months.

Because of this, battery failure rates increase in winter months, meaning service runs, repair costs, worker downtime and millions of dollars wasted.

Some fleets consider battery replacement and service costs to be simply unavoidable—but that doesn’t have to be true.

Though these batteries won’t last indefinitely, their lifespans can be maximized if properly maintained.

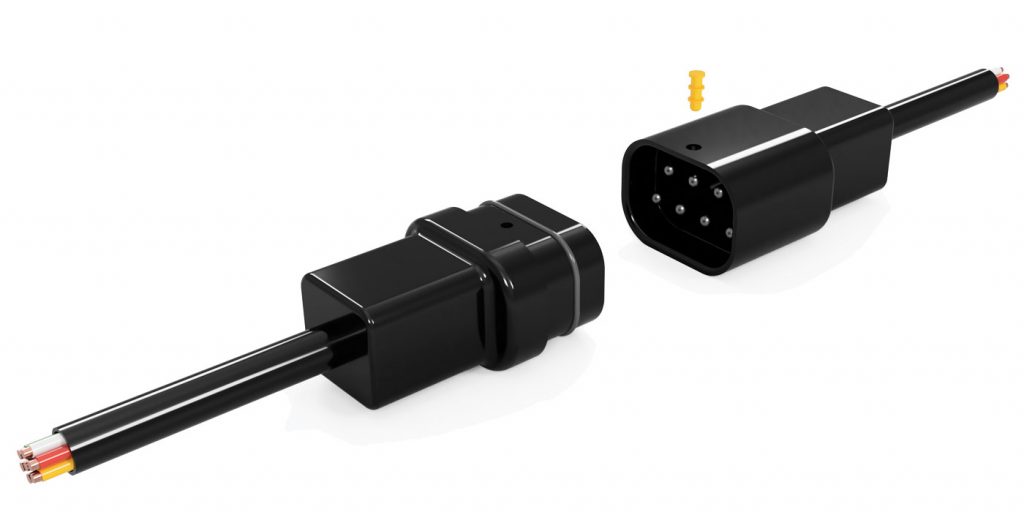

There is a direct correlation between a vehicle’s wiring and harness integrity and the health of its battery. Cable damage can lead to grounded circuit, open circuit and short circuit failures, whiled corroded cables can cause increased impedance, taxing alternators and further depleting batteries.

Wiring and harness materials become less flexible and more brittle with cooling temperatures and the cold weather will exacerbate any issue with an electrical system that is already weakened by loose connections or cracked insulation.

Drivers and fleet maintenance professionals should visually inspect lighting, wiring and harness systems more frequently, especially if the vehicle is operating in northern latitudes. Because batteries are more vulnerable in winter, an ounce of prevention is worth a pound of cure.

Cold weather conditions

The colder it is outside, the harder it is on the starter to crank the engine and pump cold, thick motor oil. The engine starter may need more time to get the engine to fire. This additional cranking time is where the potential for increased wear on the battery, starter, fuel-injectors and the gaskets in the engine comes into play. The truck may experience misfires, be unable to start or incur increased maintenance costs.

The engine starter requires a certain number of amps from the battery. The concern is the duration at which those amps will be needed. A warm engine will crank more easily than a cold one, as friction between moving parts is reduced. The residual heat warms motor oil, the engine, fuel injectors and cylinders, easing the strain on the battery and starter and providing faster lubrication to the entire system. The result is that the time needed for the starter to turn over the engine is much shorter because engine coolant and oil are already warm, noted Don Kanneth, aftermarket sales director for Webasto, which offers fuel-operated heaters that will pre-heat and circulate the engine coolant at near-normal operating temperature. So, for example, the end result may be that you are drawing the necessary amps for five to 10 seconds, rather than 30 to 60 seconds. The amp draw is the same; the cranking duration is greatly reduced with a warm engine.

For more on combating cold weather electrical issues, click here.