Typically there are four pillars to determine your true cost: Initial tire cost, mileage to removal, fuel efficiency and retreadability (or casing value). The best way to determine what’s best for your operation is to test tires by developing an ongoing tire evaluation program and comparing the tires you currently run with a possible newcomer to your fleet.

Granted, it’s not easy.

You have to track tires and take tread measurements; you have to maintain excellent maintenance practices to ensure inflation levels are correct, and that alignments stay true. And, to get results that will give you accurate information, you need to run the test tires for long haul operations to 50% to 60% of their wearable tread depth. If you don’t have the bandwidth to conduct exhaustive testing, you can still do a valid evaluation and get results that give you confidence in what to expect from selected tire brands.

Here’s how

To conduct an apples-to-apples comparison, run like-brand and like-model tractors or trucks, the same age, with the same specs. In addition, drivers comparable in skill level should run the trucks. Routes and loads should be identical, or as similar as possible. Choose dedicated long-haul routes or similar types of service for a regional or local operation.

How many trucks should be run? The more the better, but at a minimum, it should be four that are equipped with your evaluation steer tires. This will give you good average wear rate data, plus if you lose a tire due to a road hazard, you will still have three vehicles left running.

As for drive tires, you can test two brands of tires on one vehicle. The only caveat is that their diameters need to be within ¼-in. of each other. With this evaluation, you can run two trucks with eight wheel positions. The key is doing an X-pattern (or cross-axle) on the two rear axles.

However, don’t run the tires identically on the two trucks. The right rear outer tire historically wears faster than any other drive position tire due to a higher percentage of right-hand turns, which can cause scrubbing. Be sure to have brand X in that position on one evaluation truck, and brand Y on the next truck. Also, note that tires on the trailing axle typically wear about 20% faster than tires on the forward axle.

Evaluation units should be checked every 30,000 miles, or every three months, whichever comes first. The first item to analyze is tread wear, and for this you need a quality tread depth gauge that measures to 1/32nd or 1 mm.

When checking the tire, you should have three points for gauging across the tread face—the outside, middle and inside of the tread. Again, a fingertip diagnostic should be conducted as well and any signs of irregular wear reported. Irregular wear could indicate a problem with the vehicle. If the irregular wear is found to be severe, in the drive or trailer position, rotate the tires on the front rear axle in cross axle design.

After 75,000 miles, you should have solid wear data on your steer tires. With this wear data in place, you can now make projections on how many more miles the steers will last before they’re pulled for retreading. This will give you an apples-to-apples mileage comparison and provide your first cost-per-mile figure on virgin rubber, once you factor in the purchase price.

Since drive tires put on more mileage, the process will take longer. When tread is worn down by 50% to 60% you can gather your viable data and you can see how many 32nds of tread have been worn off. Once you have miles per 32nd calculated, do the math to see how your test tires are projected to do, plus factor-in what you found on casing value.

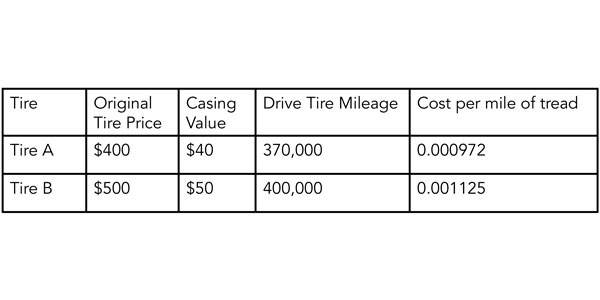

This sample calculation gives you the cost-per-mile of the tread rubber.

If you paid $400 for the tire and had a virgin casing value of $40, your net cost would be $360. If you project 370,000 miles on that drive tire, your cost-per-mile of tread would be $0.000972. So, even though Tire B had more miles to removal, it was more expensive to run and not the low cost of ownership winner.

If in your evaluation the test tire outperforms the incumbent, our recommendation is to move forward, but not all the way forward. Your evaluation gave you confidence in the new tire and how it should perform. So, begin to purchase 50% of the new tires for six months—both in replacement and through your truck OEM if available—and then if all looks good, at a year, move forward on full-tire standardization.

Gary Schroeder is global director of Cooper Tire’s Truck and Bus Tire Business.