For KLLM Transport Services, one of the more highly recognized temperature-controlled carriers in the United States, using technology to gain cost and competitive advantages has helped paved the road to success for many years. Recently, however, that need grew significantly, if not in scope then most certainly in size.

For KLLM Transport Services, one of the more highly recognized temperature-controlled carriers in the United States, using technology to gain cost and competitive advantages has helped paved the road to success for many years. Recently, however, that need grew significantly, if not in scope then most certainly in size.

In mid summer of this year, Duff Brothers Capital, owners of KLLM Transport Services, acquired Frozen Food Express Industries (FFE), explains Mike Bromhall, vice president, maintenance, Duff Brothers Capital. The FFE truckload operation is now part of KLLM and its refrigerated LTL division in Dallas is operated under the FFE name.

“As a result of this acquisition,” Bromhall says, “KLLM’s truckload operation now has 2,500 tractors and 3,500 trailers. This is an exciting opportunity, but it also means we are managing a much larger fleet at a time when we, and the industry as a whole, are facing significant challenges.”

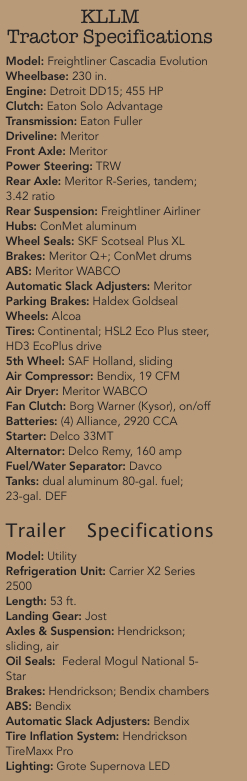

Jackson, Miss.-based KLLM provides service to a major portion of the lower 48 states and Mexico. The carrier’s fleet is made up predominantly of Freightliner power units and a combination of Utility, Hyundai and Wabash refrigerated trailers.

“One of today’s issues when it comes to purchasing and specification decisions is that our trade cycles are still very much up in the air,” Bromhall states. “With new driver hours of service regulations, it’s harder to keep average monthly mileages at the 10,000 to 11,000 mark. That means we need to go beyond our traditional 42-month replacement cycle to get to a level of utilization that makes sense.

“At the same time,” Bromhall adds, “when you’re pushing past a 42-month replacement cycle, and with the added emission components and other regulations, the cost of new vehicles keeps rising, so weighing everything is the only way to make an effective choice and warranties become even more important in getting as much value out of our equipment as possible. This is why we’re tending to spec more in the way of vertically integrated powertrains. Not only does that lead to more favorable pricing, but it also usually means there’s more a comprehensive warranty behind each OEM’s product line.”

One common spec at KLLM regardless of trailer make calls for Carrier Transicold refrigeration units on all of the fleet’s reefers. The latest are X2 Series Model 2500 units with IntelliSet, an application that lets the carrier fine-tune refrigeration unit performance to improve fuel efficiency, optimize product protection for customers and help reduce the potential for driver errors.

The IntelliSet application is built into the APX control system on Carrier Transicold’s latest refrigeration units. With IntelliSet settings preprogrammed to customer specifications, drivers can select the right profile for a specific haul on the X2 Series unit’s Advance controller.

“One thing this does is eliminate claims caused by inadvertent operator error,” says Jim Richards, KLLM president. “We talk to our customers about how they would like their products maintained and program the IntelliSet to meet their needs. The driver simply selects the customer mode. That helps us reduce our claims exposure, and it takes the driver out of the control equation somewhat.”

Early adopter

KLLM was one of the first adopters of the IntelliSet control system. The carrier has used the application since the late 1990s, working with its Carrier Transicold dealer, Southern States Utility of Jackson, Miss., to test the and implement the system. Today at KLLM, the use of IntelliSet has become institutionalized, with drivers and dispatchers trained in its function to make certain proper settings are always in use.

One of the challenges that IntelliSet addresses at KLLM is managing temperatures inside a trailer, which involves far more than picking a single setpoint. “Today’s refrigeration controls offer settings for air flow, temperature variance, system response to ambient temperatures and more,” Richards explains. “There are nearly 60 different operating parameters we can set. While that degree of precision helps generate customer satisfaction, without a tool like IntelliSet it can be time consuming to configure.”

KLLM also uses a trailer tracking system to monitor conditions inside each unit and has the capability to use satellite telemetry to update and manage IntelliSet settings remotely. “That capability removes the driver from temperature-setting responsibilities altogether,” Richards says. “Would you ever have thought the day would come that when we send a driver to pick up a load, we would be able to set the unit from the office?”

Saving fuel

IntelliSet is also optimizing fuel consumption on refrigeration units at KLLM. “Fuel savings has become an even bigger benefit of IntelliSet over the last couple of years,” Richards states. “In the past, we would often use continuous run mode for our refrigeration units, but with IntelliSet we program the unit to run based on customer specifications. If a load doesn’t require continuous run, we operate the unit in start/stop mode and that saves fuel.

“We know for a fact that we’ve reduced the run hours on our units,” Richards continues. “Typically, we would run each unit about 2,500 hours a year, and now we run about 1,600 a year. That savings of about 900 fewer hours per unit translates into nearly 2 million gallons of diesel fuel saved by the fleet annually. And the 36% reduced runtime not only saves fuel; it also brings an environmental benefit of reducing fleet carbon emissions.”

Reducing refrigeration unit runtime by more than a third, Richards adds, boosts the resale value of KLLM’s refrigerated trailers, and allows the fleet to extend maintenance intervals, which provides another savings.

In KLLM shops, Carrier Transicold units are thoroughly checked and settings are updated during preventive maintenance on every unit. The maintenance operation managed by Mike Bromhall includes a KLLM shop in Jackson, overseen by John Fitzgerald, an FFE shop in Dallas headed up by Brian Gillespie, and a KLLM facility in Atlanta managed by Danny Gray. A total of 55 tractor-, trailer- and refrigeration unit-qualified technicians work at the three locations.

Achievements

Embracing technology throughout it operations has helped propel KLLM to become one of the nation’s leading refrigerated carriers. The company lists among its achievements being the first nationwide temperature-controlled carrier to use satellite communications in its entire fleet.

Looking ahead, Richards says that merging FFE and KLLM operations will bring synergies and increased capacity that will enhance the quality service that both companies have been providing to their customers.

“Technology and cost savings aside,” Richards states, “It still comes down to customer satisfaction. At the end of the day, the goal is to provide premium service to our customers and to do so better than anyone else.”