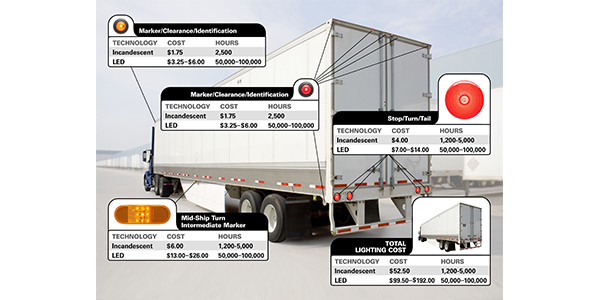

LED lights are more expensive up front, but according to lighting experts, buyers get their money’s worth. The good news is that LED lighting products typically last many times longer than their incandescent counterparts, but they are also about twice the cost. Luckily, the ROI is easy to see.

“LED lighting technology has become standard in many applications,” says Paul Sniegocki, executive vice president of engineering and chief technology officer for Truck-Lite. “While LED lighting products tend to be higher-priced than incandescent or halogen options, they offer significant advantages such as their durability due to the solid-state design.”

Today’s LED lights use only 10% to 30% of the amps needed to illuminate incandescent lamps for many applications. With the lighting drawing significantly less power, the surplus energy can be used for other electrical equipment needs. For this reason, industry experts say that LEDs are the predominant light source for most, if not all, fleet lighting applications from headlights to trailer lighting.

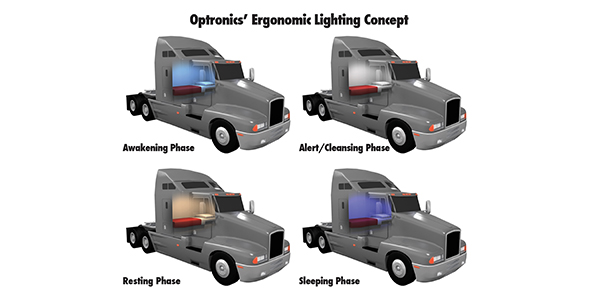

“I would have to say that we are entering the twilight of the incandescent era in truck lighting,” says Brett Johnson, president and chief executive officer of Optronics International. “As a practical matter, I can’t see why any fleet would still find value in spec’ing a vehicle with any incandescent lamps.”

“All of our lighting systems feature LED lamps except for a few spot and flood lamps, but even these are now being converted to LEDs,” says Chris Lee, vice president of engineering for Great Dane, which offers a variety of PC-rated LED lighting options on its trailers. “Our standard LED Exterior Light Package features Grote’s MicroNova DOT lamps and dual-intensity ID cluster lights, along with the Long Life Light System.”

One common misconception is that LEDs live forever. They do have a much longer life, but everything has a lifespan. Another misconception is that LEDs produce a high heat output that is enough to melt snow.

Gerry Mead, executive director of innovation at Phillips, says that LEDs actually run much cooler than bulbs and produce “limited heat.” LEDs can plug into your current wiring harness with a simple pigtail conversion or a water sealed splice.

Truck-Lite’s Sniegocki says that another common misconception is that all LED lights are the same. “While we recognize LEDs for their advantages, those advantages are only realized if designed and manufactured to meet the rigorous standards and environment of the commercial vehicle market. “LED lighting will continue to be the standard in most applications,” he notes, “while retrofitting incandescent applications already on vehicles is a common practice.”

Most reputable lighting companies offer quality LEDs with diodes that will last for thousands of hours. However, if you are looking for inexpensive options, there are plenty available online that are not very high-quality and will not perform up to expectations. Use caution when sourcing these products from unknown companies on the Internet, because you may get what you pay for.

Every LED lamp or bulb on the market has to have electronics onboard to drop the power from the 12- to 14-volt charging system down to about 9.5 volts that the LEDs run on, but the low-priced imports stop there. Some companies spend extra time to clean up the power to the chip. There’s a difference in how specific brands do that based on price and quality and so forth, but the chips like a nice, smooth, pure power source.

According to Sniegocki, diodes are rated from 30,000 to 100,000 hours of use, depending on the package and color. He says that companies must use the appropriate measures in the design and manufacturing process to ensure that the final lighting product performs up to expectations.

Because LED lighting exerts much less current draw on electrical systems than incandescent lighting, it leads to higher efficiency, something that is advantageous to any Class 8 vehicle electrical system.

Another benefit of LEDs, Mead notes, is that the connectors are more resistant to water infiltration, thus providing better corrosion protection. They also run cooler and need much less voltage to operate. In addition, they are less susceptible to vibration. The filament on lights doesn’t like to be shaken, and vibration happens out on the highway and is just part of business. LEDs fail less often, which means fewer violations.

“LED is designed to focus its light and can be directed to a specific location without the use of an external reflector, achieving a higher application efficiency than conventional lighting,” Mead explains.

Department of Transportation regulations state that all lights on a vehicle must be in working order. For trailer lights to function properly, they must be free of damage, correctly installed and receive the proper amount of power needed to operate. A clear pathway for electricity to flow to the lights on any trailer begins with a solid, corrosion-free, electrical connection. To function at its best, the electrical harness system, from the socket connection at the front all the way back to the farthest light, must be free from corrosion—and LEDs are much more resistant to corrosion.

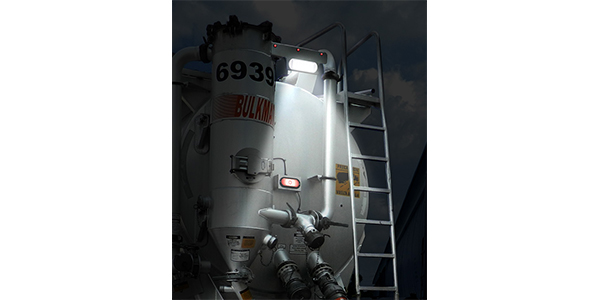

As the lighting world continues to transition to LEDs, the latest products to move in that direction are hazard and warning lights that can far exceed traditional halogen or gas-discharge options.

“Today, the entire hazard and warning light industry is undergoing a significant sea change—namely, the industry’s shift to LED technology,” says Chris Cammack of Grote Industries.

For fleet managers, what makes this move even more attractive are the plummeting prices of LED technology. Prices have decreased to the point that many vehicles that require Class 2 lights are instead being outfitted with brighter, Class 1 options given the minimal price differential.

For more electrical info, read our battery feature story here.