What you need to know about brake friction

If you are spec’ing brakes, I’m sure I don’t need to tell you that lately, the brake market is increasingly split into two categories: the tried-and-true drum brakes, and the up-and-coming air disc brakes (ADBs). Although most heavy-duty vehicles on the road still use traditional drum brakes, which cost quite a bit less than disc

Pump you up: The importance of water pumps for engines

Upgraded water pumps are one of many components that engine OEMs are putting to work to improve fuel economy. The water pump is one of the major components in the cooling systems, and the cooling system can impact fuel economy and the longevity of the engine if it’s not cooling correctly. “The cooling system is designed

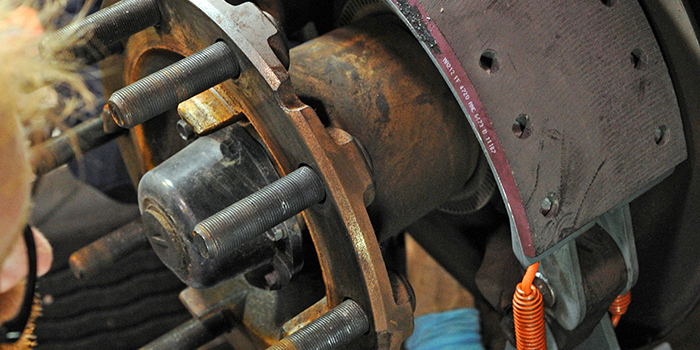

Checking truck air disc brakes

When checking your air disc brakes, be sure to follow these tips provided by Haldex. Build the air system to governor cut-out (120-135 PSI), release the parking (spring) brakes and cycle the service brake pedal until the compressor cuts-in. Note: The cut-in pressure, minimum 85 PSI bus, 100 PSI truck/tractor (FMVSS 571.121). With the compressor

Preventative maintenance to avoid CSA brake violations

There’s a lot to remember when inspecting brakes; fleets need to make sure everything is operating properly, and that potentially costly CSA violations can be avoided. Fleet Equipment polled our experts from our CSA brake story on the steps they recommend taking in a brake inspection. Read the full story on common issues that lead to CSA violations,

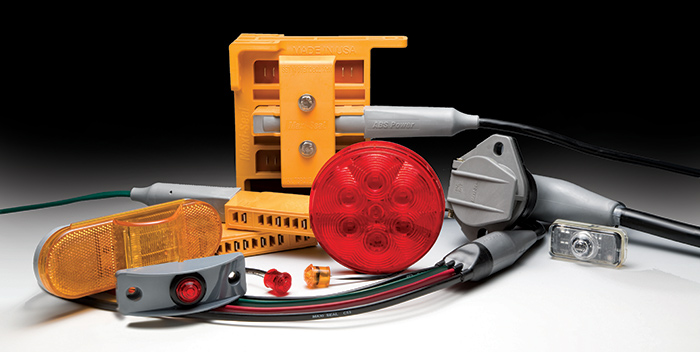

How to maintain tractor-trailer electrical connection

When it comes to tractor-trailer electrical connections, spec’ing and maintaining equipment is vital. This is especially true these days with fleets seeking to avoid CSA inspections that often lead to time off the road and costly citations. Spec the best “At Peterson, we have been actively selling and promoting our Defender sealed, modular harness and

Check your brakes: Putting a stop to brake-related CSA issues

Commercial Vehicle Safety Alliance’s CSA violations should be an unnecessary problem, especially since they can lead to costly delays, and unexpected downtime may cause fleets to lose customers not only because of delays. After citations related to lighting problems, brakes are the second most commonly penalized item—18.7% of violations handed out by the CVSA in

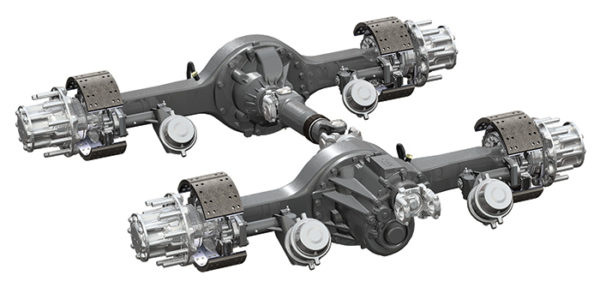

How axles improve traction and safety

A roundup of the latest in heavy-duty axles and how they improve traction and safety. Steve Slesinski, director of global product strategy, planning and management for the commercial vehicle market at Dana Inc., explains how Dana axles fit into creating better traction control, saying…

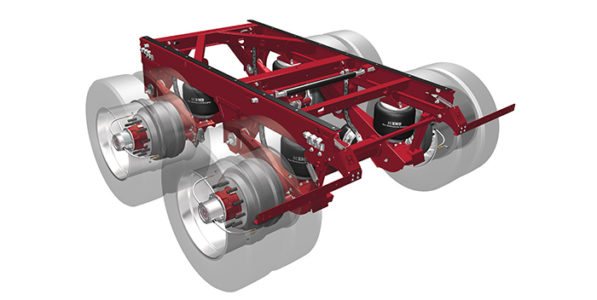

The inside scoop on spec’ing axles and brake ratings

For optimum performance and safety, brakes and suspensions need to be a match and work well together. So what do fleets need to know? Fleet Equipment asked major suppliers to provide the inside information.

PACCAR Parts opens new distribution center in Washington

PACCAR Parts’ new $32 million distribution center in Renton, Wash., is now fully operational. Servicing dealers in the Northwestern U.S. and Western Canada, the new 160,000 sq.-ft. parts distribution center (PDC) is almost three times the capacity of its predecessor built in 1973. “By investing in the latest technology and more than doubling the square

Applying the brakes: Ensuring the future of truck safety

Advanced safety systems that employ radar- and camera-based technologies that enable adaptive cruise control and even autonomous truck operation rely heavily on one specific component—the brakes. The safety of these futuristic collision mitigation systems rests squarely on proper brake application, operation and maintenance. “It’s important to keep in mind that advances in collision mitigation technology