Kent Jones doesn’t talk like he’s only held the title of SAF-Holland President—Americas for seven weeks. “SAF-Holland has a high market share on fifth wheels, as the company has had for many years—Holland is a more than 100-year-old brand—and we do very well there. We have a very strong and growing segment in the trailer side of the business for axle and suspension systems—selling as one module to our fleet customers and to our trailer customers,” he explains.

Two questions into the interview and he’s already talking high-level product strategy. “While we’re not the dominant share in that market, we have grown significantly in the last five years. It’s an exciting space and an area where we can do really well in the next decade.”

It’s early on a Tuesday morning. Kent is moving at full speed before most have had their first cup of coffee. He has analyzed financials and product line plans on his computer screen and buzzed in and out of his office to follow up on emails with a face-to-face response to SAF-Holland product managers. It’s an energy that crackles throughout the SAF-Holland offices in the middle of a makeover that features tech company inspired meeting spaces, a revamped engineering testing area and an evolving customer meeting space that charts the SAF-Holland product timeline (don’t miss the cool 1930s wooden fifth-wheel prototype) both past, present and hints at what lies ahead for the company.

Touring the facility, Kent lays out his vision for SAF-Holland, from what’s hanging on the wall to the products coming down the line to the service and support his customers’ experience.

“SAF-Holland had what I expected coming in: a really strong brand; good market shares in the marketplace; good positions with customers,” he says. “In the seven weeks that I’ve been here, I have spent a lot of time—probably over half that time—trying to learn the business from every angle, and spending a lot of time talking face-to-face with customers.”

His timing couldn’t have been more perfect. The North American Commercial Vehicle Show (NACV) was just two weeks ago and provided ample opportunity to meet with customers, in addition to his hectic travel schedule.

“At NACV, I had breakfast with a fleet trailer suspension customer,” he begins. “They had spec’d our entire axle system suspension system with an air disc brake wheel-end. They complimented the product and appreciated the benefits, but they had one application in which they saw some premature wear. It was half a percent or less than of their total purchase, but clearly we had to figure out what’s going on.

“We immediately were able to send in our field service team that not only fixed the problem, but worked with them to implement an inspection system for when the truck came into the yard so that they could stay on top of what was happening with their trailers.

“When customers have a concern or a problem, they need to be able to get that responsiveness,” he continues. “When they have a good experience, it can present business opportunities. Great service is an extension of great brand position and customer confidence. This customer ended breakfast by asking me, ‘What can we do for you?’ I was amazed by this. All I could say was: ‘Thank you very much. I appreciate your business.’”

On the NACV floor, the SAF-Holland booth was packed with tried and true hardware solutions. Its SAF CBX23 AeroBeam fixed frame air suspension system sporting its P89 air disc brake and its Saturn 62 iM landing gear designed for intermodal operations sat next to its latest technology-infused solutions—the ELI-te automatic lighting system that helps ensure a proper fifth wheel coupling and its SAF Tire Pilot Plus tire pressure management system engineered specifically for its CBX Air and ULX Spring Series suspension systems.

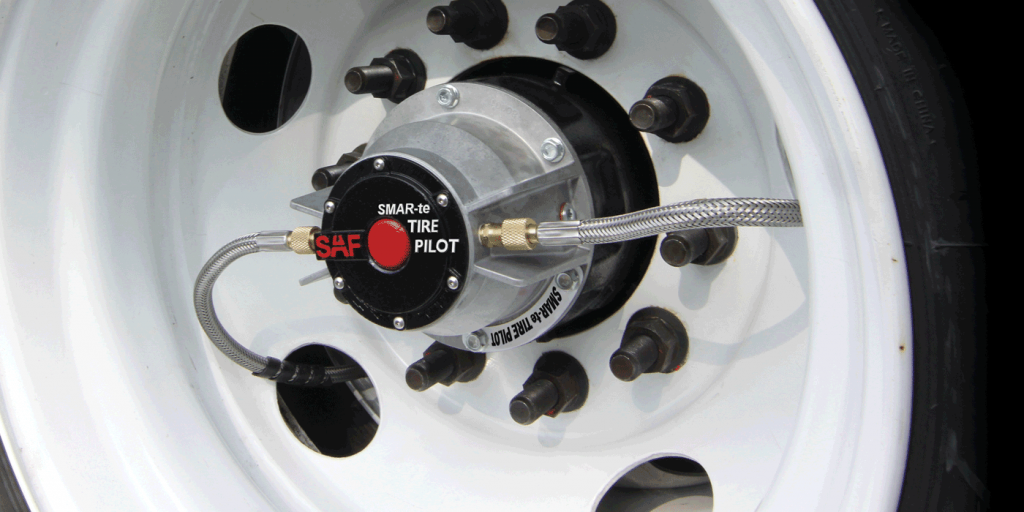

In the upper-level press conference rooms high above the trade show floor, Kent set the stage for Bill Hicks, director of trailer suspension and axle product planning at SAF-Holland Inc., to unveil its latest innovation: SMAR-te Tire Pilot. Sophisticated electro-pneumatic controls infused into its SAF Tire Pilot Plus TPMS allow SMAR-te Tire Pilot to dynamically change tire pressure up or down based on the axle load.

The announcement reflects an evolution of the role technology plays in supplier solutions. Hardware solutions are becoming smarter. And that’s no small feat for any supplier to accomplish.

“We’re innovating to support OEMs and customers with critical and needed peripheral technology so that the main technology of autonomy or electrification can work,” Kent explains several weeks after the announcement sitting in his office across from Hicks’s office where the product planning director is meeting with engineers to map out the future of SAF-Holland solutions.

“For example,” Kent continues, “the connection between the truck and the trailer—if you have driverless technology, you’re still going to need the ability to couple the truck to the trailer, and you have to have the technology to power raise or lower the trailer landing gear. That’s the type of technology that we demonstrated and continue to develop.

“But our focus is always developing solutions to further help our customers achieve the best costs per mile possible. You see it in our SMAR-te Tire Pilot that uses digital technology to inflate and deflate to more precise levels. No matter the weight of the trailer load throughout its transit route, the tires will be inflated to the proper setting for optimum tire tread life.

“Our technology is smart application digital technology; what we call ‘smart steel.’ We’ll continue to deliver that connectivity to the market.”

Delivering solutions to the market is a challenge for all suppliers, including SAF-Holland. Huge equipment demands, raw materials tariffs and challenges have made it harder for suppliers to deliver their products where they’re needed. It’s a reality that Kent is open about.

“Quite frankly, we’ve had more demand than we’ve been able to supply,” he says, laying out the challenges he has been brought on board to face down. “That has definitely put some stress on us; this is no secret. I’ve heard customers say, ‘We like you guys. We like the products. You’ve got great people. But we need you to increase your supply position to us. We need this desperately.’ We have struggled with this in the last 18 months. We have not been able to come up on our capacity curves as fast as we would like with all these headwinds from the marketplace.”

So what’s Kent’s plan to meet demand and deliver on higher customer expectations?

“Right now, as we’re sitting here in November, we’re facing a 2020 marketplace that projects a Class 8 market, where we participate for fifth wheels and truck suspension suspensions, to go down by 30%. The trailer market looks to be going down by about 18% to 20%. But that will give us half of a breath to get caught up and finish our capacity expansions that we have tried to put in place over the last year.

“We’ve been running, basically, three shifts, seven days a week. A return to an ‘average’ marketplace gives us a bit of a breather to get our manufacturing plants staffed up and prepared over the next 18 months when the market’s down. We think we can continue to grow because we have had to tell some customers, ‘I’m sorry we can’t ship at the level that you want,’ we will start to relieve those constraints.

“That’s not as exciting as a new product launch, but it’s the basic blocking and tackling that we need to do. It means rolling up my sleeves over the next 18 months to make sure we deliver the capacity expansion.”

Kent’s focus on delivering on demands doesn’t mean the innovation at SAF-Holland stops. It’s just there will be more to deliver on.

“We’ve made significant investments in e-commerce and digital tools,” Kent says. “We have a product service called Parts on Demand, or ‘POD.’ It’s an online storefront—Amazon-like—where direct access distribution and OEM partners can see all of our products. They can see pictures of them, they can see size, weight, and they can go in and place orders as well. Now, with our new POD Plus functionality, the website will automatically load our MRP system to allow users to see inventory, list pricing as it exists and better understand price levels.”

The site is customized to the user that is logged in to allow distributors and OEMs to see their specific product price point and inventory options.

“The information that our distributors and OEMs need for our customers is critical,” he says. “Customers have a truck down, they need to buy a suspension part or an air bag, our partners can buy it from us and know that they will get it. POD Plus will help create confidence.”

Confidence is the key. Confidence in products. Confidence in new technology. Confidence in the moment when Kent tells you something is going to happen that it’s actually going to happen. Given what Kent is able to speak to after only seven weeks as SAF-Holland president— Americas, it’s easy to feel that confidence.