Periodic scrap tire analysis helps fleets better control failures

While “dead men tell no tales,” scrap tires that come to a tragic end are waiting to reveal the secrets of their demise. A pile of damaged tires provides excellent information on how, when and where they were damaged, which helps fleet managers better maintain tires and train drivers to avoid similar failures in the future.

When it comes to discerning scrap tire failures, many fleets choose to work with their tire suppliers or local dealers. Some, however, are willing and able to perform the task themselves. In either case, the Technology & Maintenance Council (TMC) recommended practice (RP) 216B provides valuable graphics and descriptions of tire failures listing probable causes and actions. Shown below are three excerpts from the TMC Recommended Maintenance Practices Manual, reprinted here by permission. For more information regarding TMC and its RPs, visit www.truckline.org. [http://tmc.truckline.com] or call 703-838-1763.

Everything you need to know about tire failures can be learned by examining scrap tires. Understanding and correcting the causes of tire failures helps lower overall tire operating costs. Fleets that take the time to specify the right tire for the job––and ensure that tire pressures are monitored and maintained––have taken the first step in controlling costs.

Those fleets that scrutinize tires in the scrap pile have gone the extra mile to maximize ROI by learning how to avoid future tire failures.

Spread/damaged cord sidewall area –– casing conditions

Appearance: Radial, pencil shaped bulge in the sidewall of a radial tire.

Probable Cause(s): Wider than normal wire cord spacing. A tire with a repair may show this condition soon after being repaired, or the condition may arise somewhere along a body ply cord that has been damaged––not necessarily in the repair area.

Action: Determine the cause of the bulge. Repaired tires can often be returned to service on dual positions unless the bulge height exceeds 3/8-in. when inflated. If the cause of the bulge is not a repair or damage, contact the tire manufacturer.

Sidewall separation due to tread puncture sidewall area –– casing conditions

Appearance: A bulge or missing rubber in the sidewall located in the direct proximity of a puncture.

Probable cause: Air migration from the inside of the tire through the casing to the sidewall initiated by the puncture.

Action: Scrap the tire.

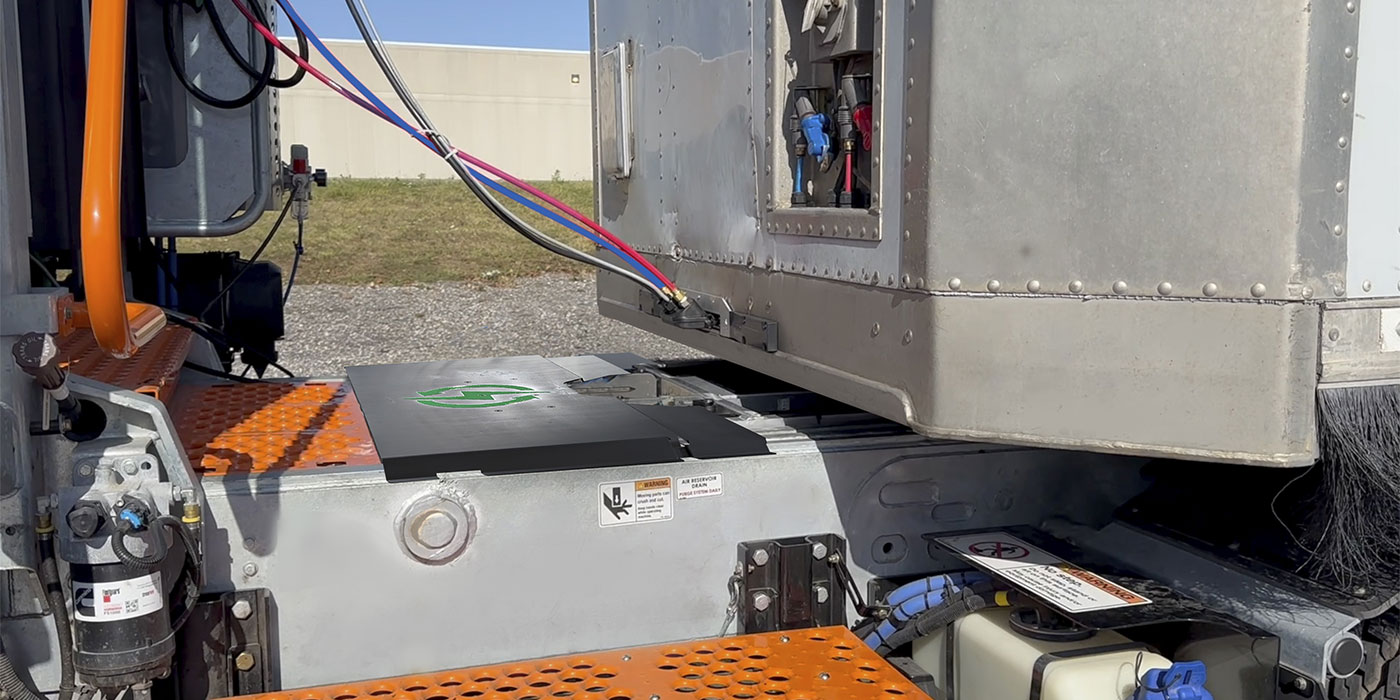

Petroleum/Chemical Damage sidewall area –– casing conditions

Appearance: Sidewalls appear swollen, soft and spongy. In extreme cases, sidewalls may be undulated or distorted. Petroleum odor may be evident.

Probable cause(s): Contamination from oil, diesel fuel, antifreeze or other chemicals.

Action: Tire: If contamination is slight, clean tire and return to service. If there is a difference in stiffness or distortion in one sidewall when compared with the other, scrap tire.

Vehicle: Check vehicle for fluid leaks.

Operations: Identify and eliminate source of contaminant.