Crawling through cramped city streets in stop-and-go pick-up and delivery applications. Driving through the dugout tire tracks of a dirt-caked construction site. Rolling through residential refuse duties. Vocational applications tackled by Class 6 through 8 trucks can place unique demands on transmissions compared to their on-highway counterparts. Yet that hasn’t stopped the trend turning toward spec’ing automatic transmissions, and catching the attention of automated manual transmissions manufacturers.

“In North America, approximately 90% of medium-duty trucks use fully automatic transmissions,” reported Otto Szalavari, Allison Transmission’s director of global marketing information and product strategy. “From the driver’s point of view, an automatic transmission means that they’re less fatigued and more focused. They aren’t distracted by the need to shift gears. They can keep both hands on the wheel and pay close attention to their driving instead of trying to find the next shift point.”

“Most medium-duty applications view a truck as a tool to do a job, and drivers are less likely to hold CDLs,” said Alison Thomas, product marketing manager for Eaton Cummins Automated Transmission Technologies. “And so all medium-duty vocations have largely adopted automation. This adoption has been driven largely by driver shortages and associated driver demand for comfort and convenience. Fleets also benefit from the safety improvements inherent in automated transmissions.”

From the truck OEM view, Volvo Trucks North America’s Allison Athey, product marketing manager for transmissions, explained that the Volvo I-Shift AMT for severe duty comes standard for its Volvo VHD. “Expansion of our I-Shift portfolio, with the addition of the I-Shift with Crawler Gears will continue to drive growth of I-Shift sales in the vocational market,” she said.

Mack Trucks reported that its mDrive automated manual transmission makes up more than 88% of its build, and growing, which is an impressive stat from an OEM that is traditionally viewed as a vocational workhorse.

Clearly, the odds are stacked in favor of automatics and AMTs if you’re spec’ing a vocational truck this year. So let’s dive into your options.

Automatic applications

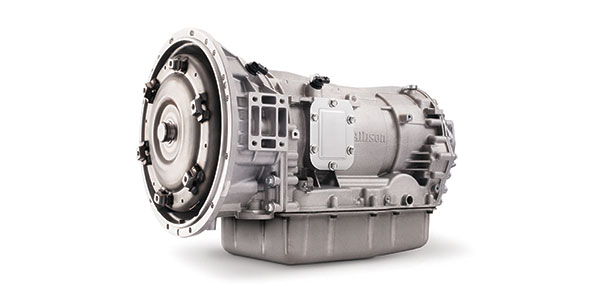

The offerings from Allison Transmission are fully automatic. So what makes a transmission fully automatic versus an automated manual transmission? I’m glad you asked. I put that same question to Szalavari and he dove into the explanation of uninterrupted power.

“When you shift a manual or automated manual transmission and engage the clutch, the engine torque is interrupted and that power isn’t getting transferred down the drivetrain to the wheels,” he explained. “In a fully automatic transmission, the torque converter allows you to shift gears without interrupting the torque going from the engine to the wheels.”

Allison Transmission refers to this as its Continuous Power Technology, which is also leveraged by Allison Transmission’s newly announced nine-speed automatic transmission. According to the company, the nine-speed transmission provides increased fuel savings as the gear train allows the torque converter to lock up early in first gear. Szalavari said that it offers a five to seven percent increase in fuel economy when compared to the Allison Transmission six-speed transmission.

Contributing to the increased fuel economy is an integral engine stop-start system that provides immediate transmission engagement and vehicle hold while the engine is restarted. Additionally, FuelSense 2.0, Allison’s software and electronic controls packages, uses DynActive Shifting to provide a variable combination of shift points, allowing fleet managers to balance the transmission via the ECM within a range of efficiency and power as opposed to setting the transmissions behavior at single point.

The nine-speed was designed to utilize the same OEM interfaces as its six-speed predecessor to integrate into vehicles currently released with the Allison 2000 Series.

Eaton Cummins Automated Transmission Technologies’s primary offering within the medium-duty space is its Procision seven-speed transmission, with horsepower ratings up to 300 HP and maximum GVW ratings increased to 35,000 lbs. on air brake-equipped vehicles and 33,000 lbs. on Park Pawl-equipped vehicles.

The seven-speed transmission’s dual clutch design and electronic shifting that uses grade, vehicle weight and throttle input is suited for urban density and high traffic operating environments, as well as hilly operations where smooth, continuous delivery of torque allows drivers to have more control in forward and reverse gears. The company explained that the dual clutch technology allows for more efficient acceleration from a stopped position and to optimize shift points that will efficiently get to the highest gear. Gear changes are made by swapping the engine torque between clutches with the next gear preselected.

The dual clutch module is fully contained within the transmission, hydraulically controlled and oil cooled for extended life. A five-spring damper is used to control torsional vibrations and is fully sealed to eliminate contamination. Procision also features Dynamic Shifting, which allows the transmission to automatically switch between economy and performance shift schedules based on mass, grade and driver demand. Base shift results are modified dynamically based on available torque, engine acceleration and grade.

Procision’s optional and adjustable Urge to Move and Creep Mode features provide low-speed maneuverability. Creep Mode allows controlled low-speed parking lot and loading dock driving without applying the accelerator. Forward and reverse creep speeds are independently adjustable to allow a customized lower speed in reverse. Additionally, Economy and performance shift tables can be adjusted to tune an overall calibration to meet any customer’s specific needs.

See the Urge to Move and Creep Mode features in action in our video here.

An automated focus shift

Automated manual transmissions have certainly made a name for themselves within the on-highway, Class 8 market. In fact, Volvo’s Athey stated that more than 90% of Volvo Trucks sold in North America feature the Volvo I-Shift automated manual transmission paired with a Volvo D11 or D13 engine. And though AMT market penetration lags behind in vocational applications, manufacturers have added features to AMTs to fit them to hard-working vocational demands.

Volvo’s I-Shift for Severe Duty features hardened gears and other hardware to help withstand frequent shifting in rugged operating environments. It also features a high-range hardened cone, improved split synchronizer components and main box parts fashioned from reinforced material. Additionally, the I-Shift SD uses higher-viscosity oil that allows for operation at a higher ambient temperature, and it features a new transmission cooler mounted to the transmission. As part of the 2017 powertrain lineup, Volvo introduced the I-Shift with Crawler Gears; the 13- or 14-speed variants are aimed at slow-speed precision applications like curb pouring.

“Road paving is another application that benefits from an automated manual transmission,” Athey said. “Volvo offers a Paver Assist feature for the Volvo I-Shift that lets drivers engage drive without first applying the brakes when transitioning from neutral (being pushed by a paver) to operation (pulling away). This helps eliminate a disturbance in the pavement-laying process.”

For its Fuller Advantage, Eaton Cummins Automated Transmission Technologies expanded its series of Fuller Advantage automated overdrive models for vocational applications last year and continues to see interest in AMTs for vocational applications. Tricked out for vocational applications, the Fuller Advantage sports an 110,000-lb. GCW capability, six- and eight-bolt PTO openings, as well as urge to move, blended pedal and creep mode features for low-speed maneuverability.

“Urge to move is one example of commercial vehicles adopting ‘car-like’ features, and improving vehicle maneuverability,” Thomas said. “Additional gear ratios allow for smaller step sizes to improve shift performance and maximize fuel economy. Hill Start Aid, for example, prevents vehicle rollback on grades.”

Additionally, the UltraShift Plus is compatible with two-speed axles and is focused on dump and heavy haul applications. The UltraShift Plus transmission features a self-adjusting electronic clutch, intelligent shift selection software, weight computation and driver throttle commands, in addition to vocational-friendly features: A hill start aid feature to prevent rolling while on steep grades and allowing for smoother vehicle launches; a creep feature for significantly improved maneuverability with continuous low-speed control; and six- and eight-bolt, as well as through shaft, power take off options.

Mack’s mDrive HD AMT is available in direct or overdrive configurations with two options: a 13- speed with low reduction gear ratio designed for easier starting on steep grades or when the truck is under heavy load; and a 14-speed, available only in an overdrive configuration, which adds a second ultra-low-speed reduction gear designed for curb pouring applications or low-speed, heavy-haul maneuvering, according to the OEM. Both transmissions offer up to four reverse gear ratios.

The Mack mDrive HD models share their architecture with the standard mDrive HD, including reinforced internal components and the same gear ratios for the 12 forward speeds. The addition of the low reduction and multispeed reverse gears is made possible by a short extension added to the front of the transmission case, Mack explained.

The mDrive updates also included several improvements to power take-off (PTO) controls, Mack reported, including new main cab harnesses for all mDrive models, a reinforced range housing to handle higher PTO bending torque and a new cab-mounted Body Builder Module.

According to Daimler Trucks North America’s Kary Schaefer, general manager of marketing and strategy, and Kelly Gedert, manager of Freightliner and Detroit product marketing, the OEM is currently rolling down its roadmap to expanding PTO and vocational options for the DT12 AMT.