Bruce Stockton, president of Stockton Solutions, is no rookie when it comes to selecting electronic onboard recorders (EOBRs) and telematic systems for fleets. His experience dates back to the late 1980s, when former employer CFI of Joplin decided that an onboard device to record and display fuel mileage—and other key driver feedback data—would be valuable.

According to Stockton, “The systems back then were unproven, unreliable and there were plenty of snake oil salesmen trying to make their mark on the trucking industry.” Fleets need to understand why a step process of evaluating and deciding which system is best for their fleet will be a wise investment of time.

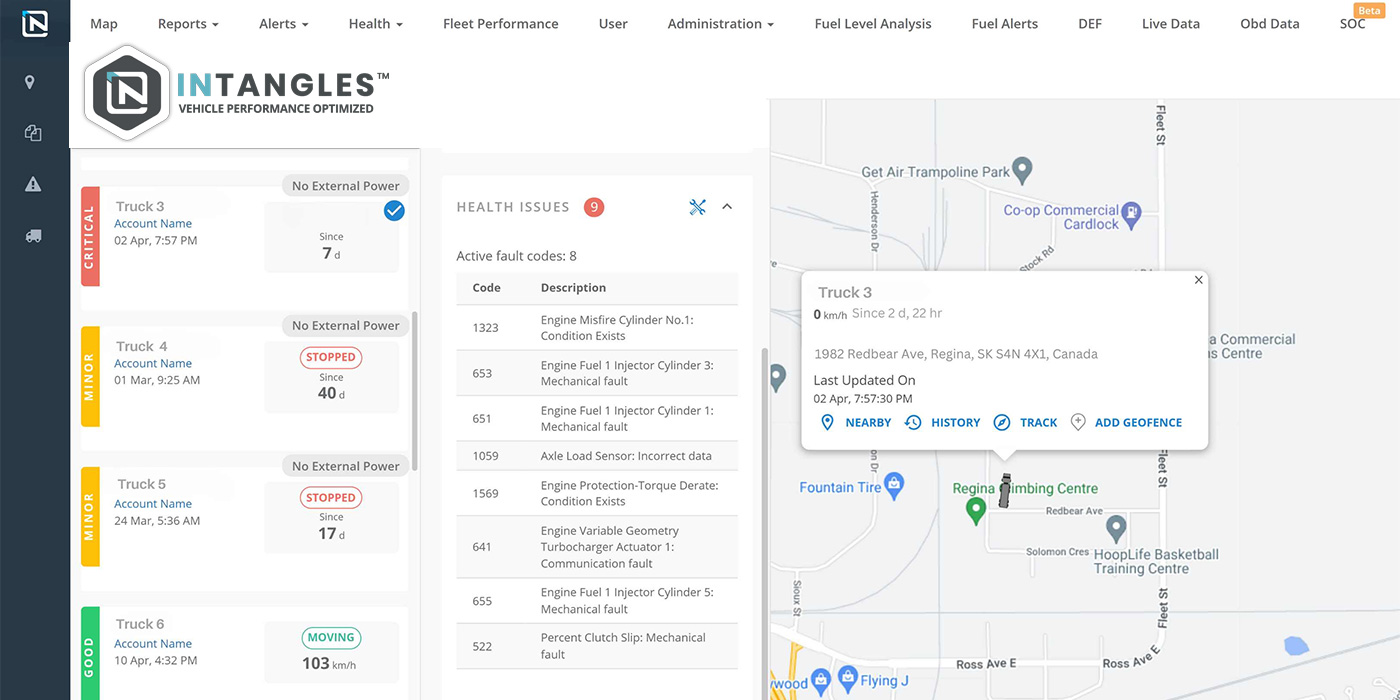

With the evolution of electronically-controlled engines in the early 90s to today’s highly sophisticated onboard diagnostic systems, having systems to transmit real-time data and then be able to massage the information to extract useful exception reporting has proven to be very valuable. Stockton participated in a fleet benchmarking study, just released by the North American Council for Freight Efficiency (www.nacfe.org), which has confirmed that vehicle aerodynamics and efficiencies can only improve to a certain level. Past that, the real gain in fuel and freight efficiency comes through the collection and analysis of accurate data followed by the implementation of action plans to improve what’s measured.

What some fleets continue to miss is that in addition to measuring driver performance and productivity, they also can measure the performance of back office operations to compare productivity of a fleet vehicle to how well the asset is being utilized.

Fleets should look at the likely mandate of EOBRs as an opportunity to get “on-board” with the program and start to utilize the data they are receiving to measure performance and improve utilization, thus increasing profits. Stockton recommends the following procedure when selecting an onboard system:

1. Besides federally mandated requirements, make a list of what change you can positively affect in your fleet. This list becomes the criteria for selecting system hardware and a provider. Put another way, where are your problem areas that are driving your costs up?

2. Look for a vendor that’s been in the business at least five years and has a strong list of references. Ask vendors for a list of their current and past customers. Get on the phone and talk to those fleets to see why they picked who they did.

3. Involve fleet IT resource personnel to make sure current back office systems are compatible and that integration of the new data into your system is not just possible, but relatively simple.

4. Steer clear of new products until they are proven.

5. Assign a “champion” within your company that knows the operation. This person shouldn’t be tasked with this project as a part-time job, unless your fleet is on the small side. The project leader will have to already possess a well-rounded level of knowledge of your business and be able to work well with your IT, safety, maintenance and operations departments.

[email protected]

www.stocktonsolutions.com