Trucks’ electrical systems grow more complex with each passing year. In the past, before the advent of the onboard computer systems, circuits were more likely to keep functioning with corroded terminals, wire insulation hardened and splitting, improperly spliced wires and any number of other issues.

With today’s sophisticated electrical systems, proper testing practices and repair procedures are critical in ensuring a proper diagnosis and repair. Let’s take a look at some of the potential problems and solutions that may be encountered.

First, many diagnostic tests ask the technician to back-probe a terminal at a component to measure voltage with the circuit intact. Performing a back-probe at the terminal can force an otherwise loose connection at the terminal to make contact. Thus, to help avoid a false reading, placing the probe in different points may prove helpful to avoid making a false connection.

On the other hand, back-probing a connector also carries the potential of forcing a terminal connection open, creating a loose connection situation that did not previously exist. Causing a loose connection this way may lead to missing the problem that brought about the original complaint.

RELATED: Click here to read more service tips.

Try to avoid the temptation to push a little harder on the probe when it appears that no connection is made. This harkens back to when I was learning about transmission repairs—if the parts don’t go together, that does not mean you get a bigger hammer to make them fit; simply look and see what’s causing the problem. In any event, when using the back-probe method for circuit testing, use caution and follow recommended published service practices.

Second, jumper wires are a great way to test circuits that are not easily accessible. Unfortunately, jumper wires are also a great way to find a short circuit that caused damage to a “fuse” or wire that burned in a circuit. Jumper wires may be of heavier gauge than the wire in the original circuit. Therefore, it is recommended to use fused jumper wires to avoid causing damage to the rest of the circuit. Check service information for recommended amperage protection on jumper wires or the amperage protection determined by the vehicle fuse for that circuit.

Third, applying power to an electrical component could result in damage to the component. Many components are designed to operate on power significantly less than full battery voltage. Consequently, connecting battery voltage to these components may damage or destroy the component. When the service procedure instructs to apply voltage to a component, make sure the voltage is at the requested specification.

Each of these cases presents a problem that could completely mask the true problem with the circuit. As a result, the repair made to correct the assumed problem only corrected the problem we introduced during the testing, not the actual problem. This means that the original problem likely still exists and will result in additional cost and downtime.

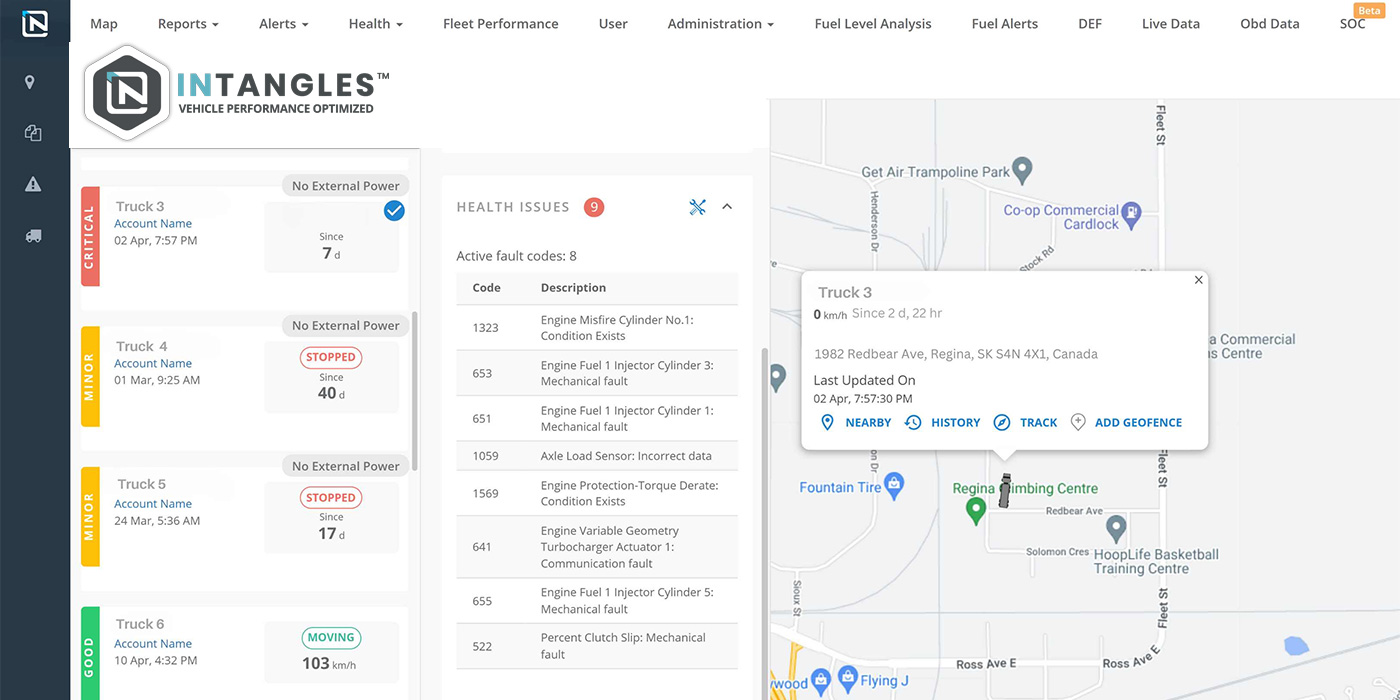

Obviously, nobody wants to have unnecessary repeat visits to the service bay. We are in a very different era of electronic diagnostics compared to just a few years ago. It pays in time and reputation to make the effort to study the testing practices needed for today’s vehicles. Gaining knowledge is time well spent.