Tech Tip: Ten tips for daily brake lathe maintenance

Like any equipment, your brake lathes need regular care and maintenance to operate at peak efficiency. Keep your brake lathe running smoothly by following these 10 daily tips. Important: Before making any inspection, adjustment or repair, disconnect the power source and lock out all moving parts to prevent injury. Always wear protective clothing and eye

Tech Tip: Eight steps for proper transmission jack maintenance

Installing a new transmission or removing the old one can be a challenge without a properly working transmission jack. These powerful, multitask lifting systems are essential in most repair shops. However, transmission jacks can only do their jobs if they are properly maintained, regularly inspected for damage and used correctly. Here are eight tips for

The ABCs of winter trucking prep: Controls

In the ongoing “ABCs of winter trucking prep” series of tech tips from Bendix, the “C” is for controls. “Driver assistance technologies, such as stability and collision mitigation systems, may be called upon more often in wintry road conditions, while tire pressure monitoring systems are valuable in keeping proper inflation during temperature swings,” said TJ

The ABCs of winter trucking prep: Brakes

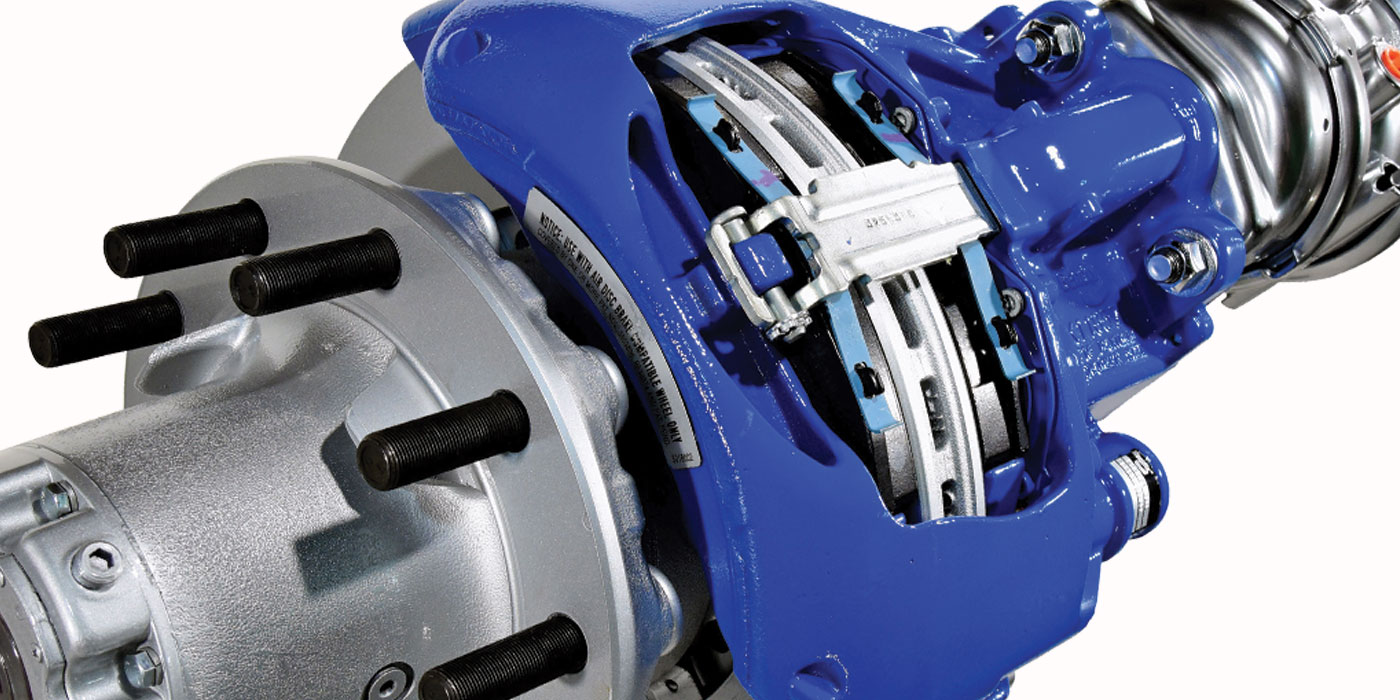

In the ongoing “ABCs of winter trucking prep” series of tech tips from Bendix, the “B” is for brakes. “At the wheel ends, the onset of winter weather means paying extra attention to brake components,” said Mark Holley, director of marketing and customer solutions—wheel-end. “During pre-trip walk-arounds, drivers should look at the air brake chamber

The ABCs of winter trucking prep: Air systems

Freezing temperatures; snow and ice in the air and on the ground; corrosive road treatments: Winter throws a lot at truck drivers and their vehicles. With an eye on keeping trucks in good operating condition in cold and nasty weather, this installment of the Bendix Tech Tips series provides reminders on taking proper care of

Tech Tips: Five tips to keep your floor jacks from getting jacked up

Most well-made floor jacks will have a long service life in the shop if they are properly maintained. Like all equipment, floor jacks should be inspected regularly for damage and kept clean. The owner’s manual is the best source for specific recommendations on lubrication, when to change the hydraulic fluid and other maintenance requirements. The

Tech Tip: Is your stowage doing more damage than good?

With winter upon us, wet weather and de-ices are more prevalent than ever, which is the perfect storm (no pun intended) for corrosion build-up on a vehicle. While the electrical connections of a plug and socket union are a primary location for corrosion build-up, there is another place that could be doing more damage to

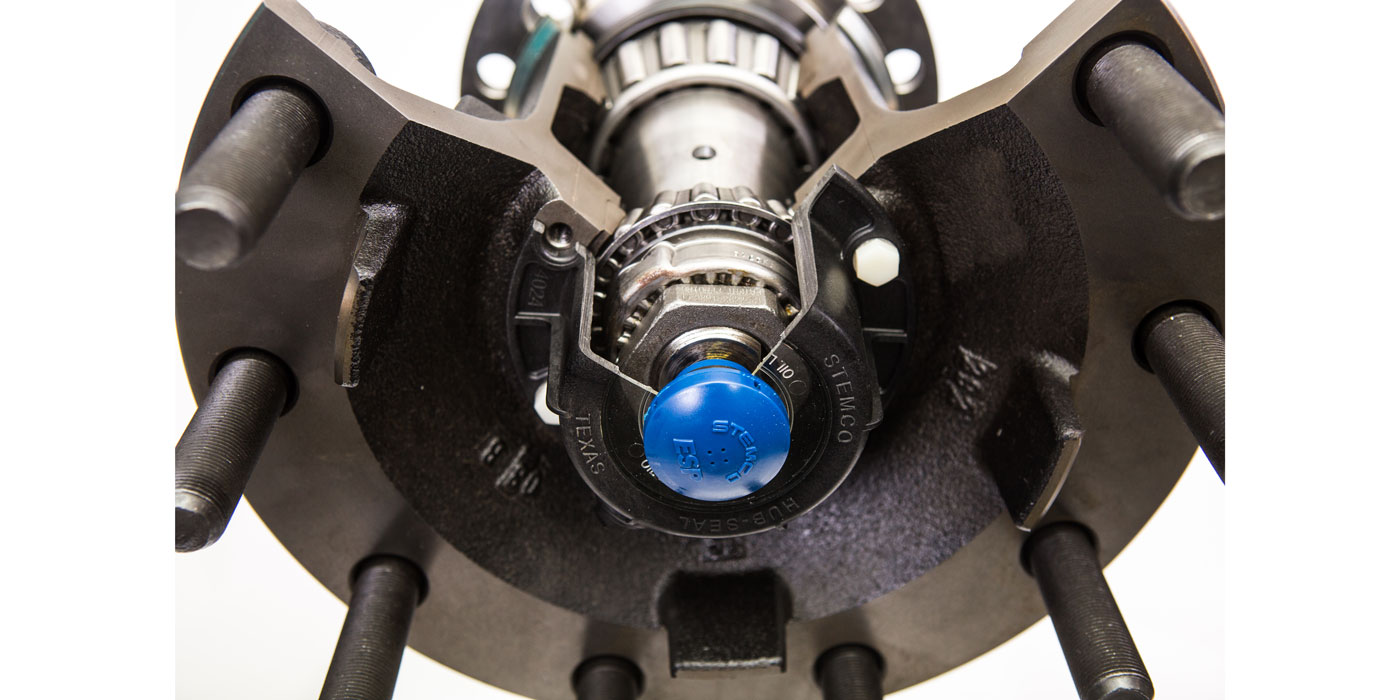

The importance of keeping contaminants out of your truck’s wheel ends

The trick to extending the life and performance of your wheel end starts with something that is simple, but often overlooked: prevention. And while you’ve likely heard why it’s a good idea to keep contaminants away from wheel ends, you may not know exactly where those contaminants are coming from—or the damage they’re actually doing.

Tech Tip: Avoid cracks in air line adapter fittings

The image below shows a crack in the swivel nut of a JIC-style air line fitting. However, these cracks are not due to a defect in the manufacturer’s build but rather missteps made during the install process. These cracks can result from over-tightening trying to obtain a complete seal if an air leak is detected.

Checklist: Make sure your fleet is prepared for winter

Preparation is key when it comes to facing the cold weather that lies ahead. Creating a thorough checklist to ensure your safety is vitally important. You’ll want to include steps that cover best practices, make sure your vehicle is performing optimally, and confirm that all essential tools are on board. The following checklist provided by

Preventive maintenance truck tips for automatic slack adjusters

Time and miles: Both seem to roll by more quickly than we realize. Consider six months, 1,800 operating hours, or 50,000 miles – for many working trucks and truck drivers, those aren’t long intervals: But they’re key markers for a piece of basic wheel-end preventive maintenance that’s too often overlooked. This installment of the Bendix

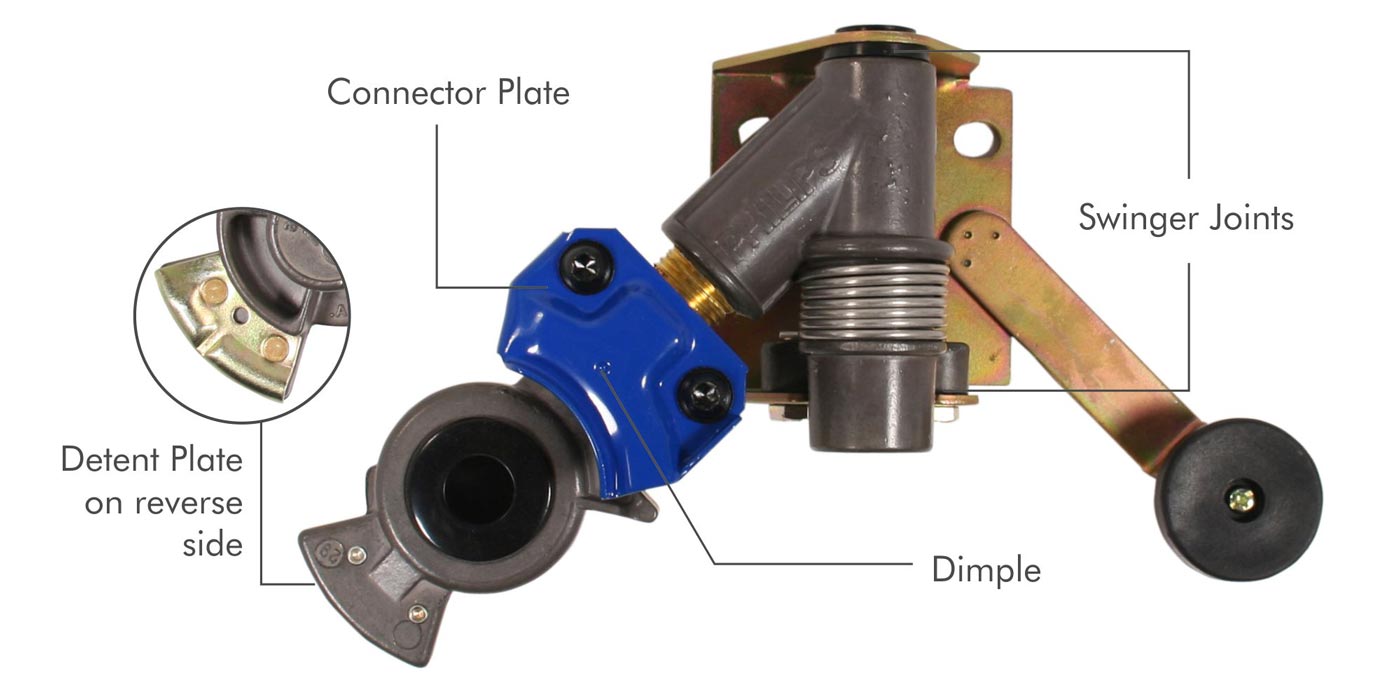

Tech Tip: Swinger gladhand general care and maintenance

Swinger gladhands were designed to help eliminate damage due to pull-away or tight/jackknife turns, and to reduce impact where straight or angled gladhands are exposed to damage. They also reduce wear on your air lines by following the movement of the tractor, reducing the bending and flexing at the tractor gladhand. To keep swinger gladhands