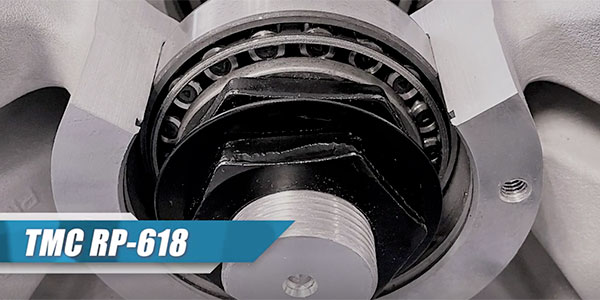

Tech tip: Proper truck wheel bearing adjustment

It’s important to know what the proper bearing adjustment is to reduce premature bearing failure. For optimal bearing life, you want to have an ideal bearing end-play setting between 0.001 inches and 0.005 inches in heavy-duty wheel-end applications. To eliminate the guesswork, the TMC RP618 was designed for heavy duty wheel bearing adjustment and allows

Drastically reduce tank trailer drag and weight for increased ROI

A 10 percent decrease in weight can result in a 6.6 percent increase in fuel efficiency, according to the U.S. Department of Energy. Even a slight reduction in weight can translate into thousands of dollars in fuel savings or allow a fleet to increase trailer payload. For those reasons, Air Products and Chemicals, Inc, a

Tech tip: Case hardening vs. through hardening truck bearing components

Do you ever lie awake at night thinking about how to harden steel to the required level for bearing components? I know I do. And that got me thinking of how important it is for a fleet manager to know the differences between through hardening and case hardening. Iron mix needs a certain amount of

How Hendrickson works with OEMs to deliver hard-working, driver-friendly suspensions

The best truck equipment solutions aren’t created in a vacuum. Relationships are everything in the trucking business, and that’s true when talking about OEMs and suppliers. Take the newly unveiled Western Star X-Series trucks, for example. The 49X and the 47X–purpose-built from the ground up to tackle the toughest vocational tasks. The field work for

Combating Corrosion – How trailer makers are preventing moisture from leading to higher trailer costs and shorter service life!

Combating corrosion on both sides of the trailer flooring is the answer, and only one trailer flooring manufacturer continues to innovative and bring new types of flooring and floor saving solutions to market each year!

Diagnosing codes on heavy-duty vehicles

Codes are not complex. They are set when the data from a sensor or component falls outside of the normal operating parameters. Also, codes can be set when the control module detects an implausible input or result for a given situation. This is often referred to as the “criteria” for setting the code. All codes

Your Last-Mile Delivery Tire Choice

The last mile. It’s always been a challenging mile. In the past, deliveries to grocery stores, retail centers, and strip malls had its variables. Bad weather, traffic, crazy drivers, and vehicle problems had to be planned for, in order to improve efficiency and elevate profitability. Logistics optimization strategies were put in place, to save minutes

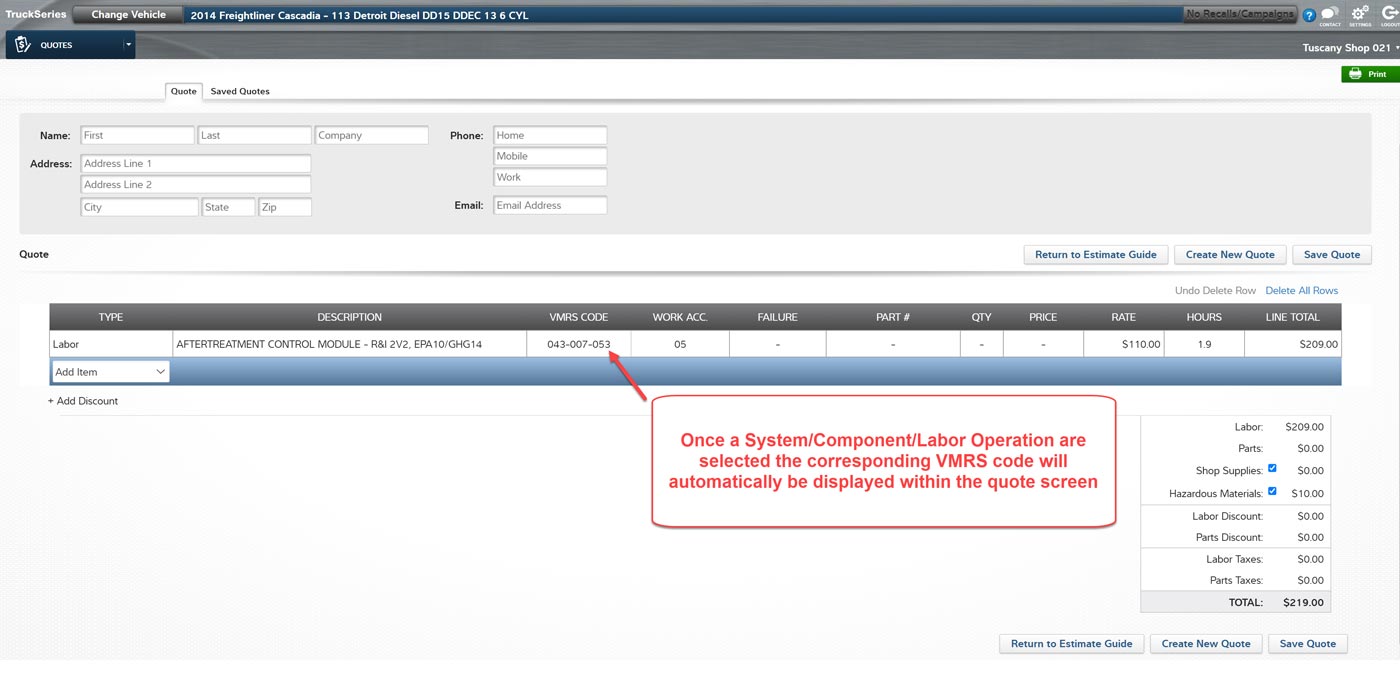

The value of VMRS in your shop

It’s important to have everyone involved in the truck repair process speaking the same language. This may seem obvious, but it’s easy to overlook how much time is saved when there is consistency across your fleet, your service providers and even the OEMs. It’s for this exact reason that the Technology and Maintenance Council (TMC)

How much could you save by switching engine oil?

Ask any over-the-road fleet what makes up their largest annual cost and there’s a good chance you’ll hear the same answer again and again: fuel. Depending on the size of the fleet, it’s not uncommon for this price to reach tens or even hundreds of thousands of dollars every year. For these fleets, improving the

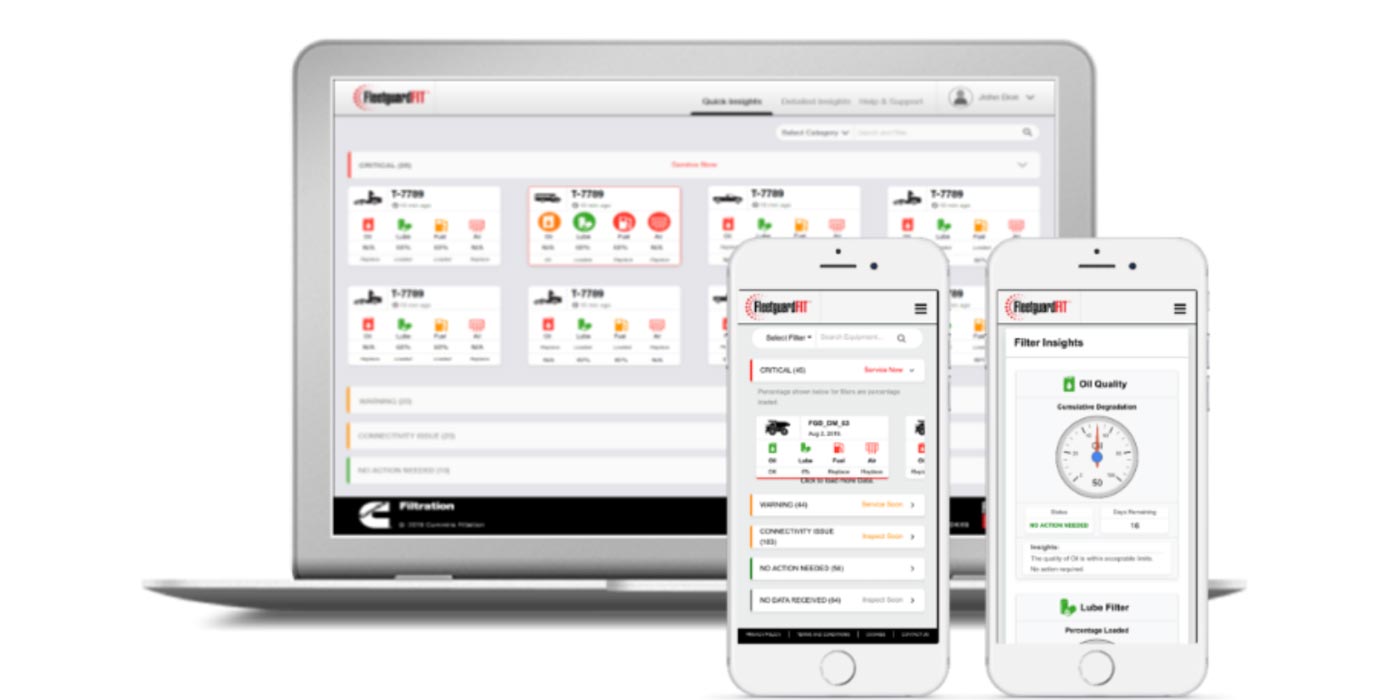

The benefits of moving your fleet to a condition-based maintenance program

Controlling maintenance costs, hitting that perfect level where costs are under control as much as possible, uptime is maximized and unplanned events are limited: these are the things that keep fleet managers up at night, and the things that drive many of their spec’ing choices. But it’s also worth thinking about your trucks’ maintenance intervals.

Expediting Collision Repairs with Electronic Estimating

AUTOMATED SYSTEMS CAN INCREASE ACCURACY, DECREASE DOWNTIME The top priority for any fleet operation or commercial equipment repair center is to keep vehicles where they belong—on the road. Routine scheduled maintenance will go a long way in achieving this goal, but when an accident occurs and takes a commercial vehicle out of action, getting it

The 8 most common wheel bearing maintenance issues

Wheel bearings may not be the first item you think of when making your fleet’s maintenance checklist. There are bigger components—the engine, the tires, the safety system—that, just by their nature, demand more of your attention. But that does not mean that wheel bearings can be swept under the rug, as failures can lead to