It’s important to have everyone involved in the truck repair process speaking the same language. This may seem obvious, but it’s easy to overlook how much time is saved when there is consistency across your fleet, your service providers and even the OEMs.

It’s for this exact reason that the Technology and Maintenance Council (TMC) of the American Trucking Associations (ATA) established the Vehicle Maintenance Report Standards (VMRS) all the way back in 1970, as a way to have all maintenance codes speaking the same language, so to speak.

VMRS seeks to codify every maintenance job to eliminate confusion and provide transparency to the jobs done on vehicles – regardless of where the work is performed.

Fleet repair shops that use VMRS enjoy some distinct advantages over those that do not. According to Kristy LaPage, business manager for the commercial vehicle group at Mitchell 1, those advantages begin with profitability and efficiency.

“Being able to easily capture all aspects in the shop and on the vehicle is key to controlling operating costs,” she explains. “VMRS easily identifies problems that are going through your fleet by using the coding method as opposed to reading, and deciphering, multiple RO’s.”

LaPage adds that this eliminates the guessing game, resulting in the ability to make accurate decisions on items like maintenance schedules and parts costs.

Gathering this information starts with the technician.

“It’s important for a technician to have tools in the shop that allow them to do their job quickly and accurately. VMRS is one of those tools,” she says.

This is why it’s important to have VMRS incorporated directly into your shop software.

Mitchell 1 announced this summer that it was adding VMRS codes to its TruckSeries suite of truck repair software solutions for Class 4 to 8 trucks.

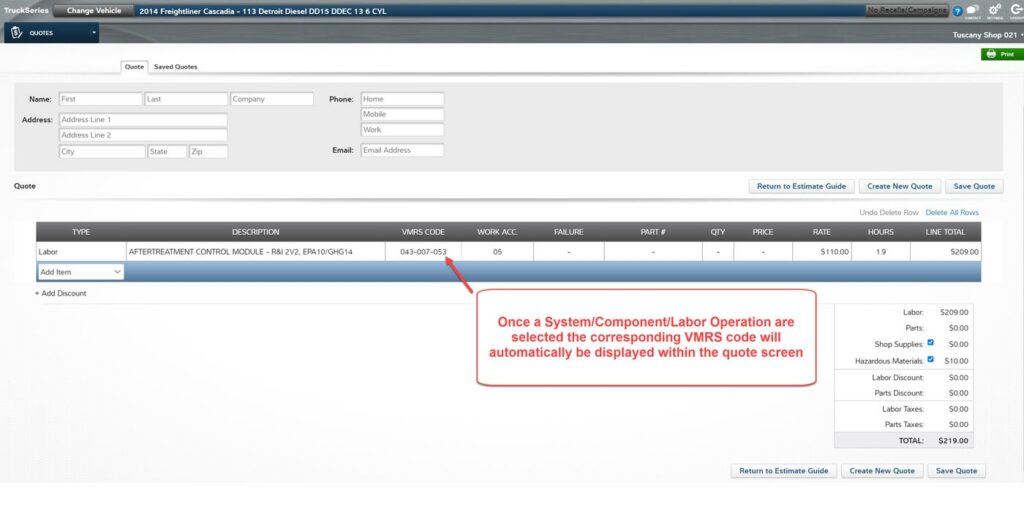

Repair facilities using the Quotes Module in TruckSeries will be able to easily map labor jobs to VMRS codes, giving the vehicle owner a clear and consistent record of repairs and overall costs for each truck in operation. VMRS codes display automatically, eliminating the need to manually look up the appropriate VMRS code for work in progress.

“Utilizing the standardization that VMRS provides reduces the time spent and eliminates the frustration that comes with completing vital paperwork with manual VMRS lookups,” LaPage explains. “When VMRS is integrated into your shop software it takes pressure off the technician. An example of this integration can be found in Mitchell 1’s Labor Guide. Mitchell 1 has mapped VMRS code to the different labor operations leaving only the failure code to be completed by the tech. So now estimates and repair orders can be VMRS coded while the shop and technician work the way they always have – without having to refer to complicated lookups to report the services they’re performing.”

If a shop is using the Mitchell 1 shop management system, Manager SE TruckEdition, the code is automatically stored with the repair order.

If you haven’t made use of VMRS in your shops before, you may wonder what you need to know to get started and to use it properly. One important resource is, naturally, the TMC.

“From researching and learning the system to implementation, TMC is a partner and resource you will be glad you have,” LaPage says.

“Additionally, while VMRS coding offers the ability to have standardization for reporting, ease of use is key. If a technician is struggling looking for or deciding on the proper code to use, records can quickly become less useful,” she says, adding that this leads to a system of “garbage, in, garbage out” that your shop will naturally want to avoid.

To learn more and get a free demo of TruckSeries visit Mitchell 1.