The ATA Technology and Maintenance Council (TMC)’s Vehicle Maintenance Report Standards (VMRS) program was started in 1970 with the goal of developing a standard method of communication for everyone involved in the truck maintenance process, from fleets to repair shops to OEMs.

Recently, the VMRS Codes Committee determined that VMRS needed more flexibility to describe the maintenance status of a part, system or vehicle.

A quick refresher: VMRS is made up of a series of unchanging codes used to describe virtually every facet of the maintenance operation, from parts to manufacturers to technician work to vehicle location. The system is set up so that no matter what terminology is used by each party involved in the service, they will all be able to be universally translated, so to speak, into VMRS. Examples include: Code 1: Equipment Location; Code 2: Equipment Category; and Code 14: Reason for Repair, to name a few.

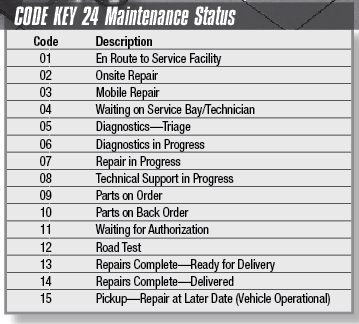

The new code key, VMRS Code Key 24: Maintenance Status, was developed to improve communication and make the information about where each part or truck is in the maintenance process easily dispersed to each interested party.

“Maintenance status codes will bring a standard, data-driven method of communicating the maintenance progress of any type of repair,” says Jack Poster, VMRS services manager for TMC. “It helps replace anecdotal information with actual data, allowing for better maintenance communication between a fleet and a service provider or within a fleet. It will also give fleets a method for tracking downtime trends and what might be causing delays. It will also provide another method to compare shop productivity using standard terminology.”

The VMRS Codes Committee created 15 codes to be part of this code key and identify different types of delays that might occur.

“We wanted to start with what the committee thought were the most pertinent examples of what might be happening during a maintenance event,” Poster says. “One thing to remember is that VMRS is a living document, so new codes can be added at any time.”

VMRS hopes that the addition of this Code Key will make the maintenance and service process smoother and more transparent for all involved.

“Fleets should check with their maintenance software providers—they can provide the new Code Key, if they are updating their software with the latest VMRS codes,” Poster adds.

Those interested in Code Key 24 can contact Poster at [email protected].