Biodiesel is a sustainable fuel that has grown in popularity as a cleaner-burning alternative to petroleum diesel. It’s made from renewable resources that would otherwise have no further use, including recycled cooking oil, waste animal fats and vegetable oils. In most cases, it’s blended with petroleum diesel. For example, a common blend is called “B20,” meaning the fuel is 20% biodiesel and 80% petroleum diesel.

Recently, some forward-looking organizations have been using higher blends, including B100, to take even greater advantage of the environmental benefits of biodiesel. Read on for answers to the most commonly asked questions about B100, its benefits, and how it can significantly reduce emissions and protect your bottom line in the long run.

How does B100 work in a diesel vehicle?

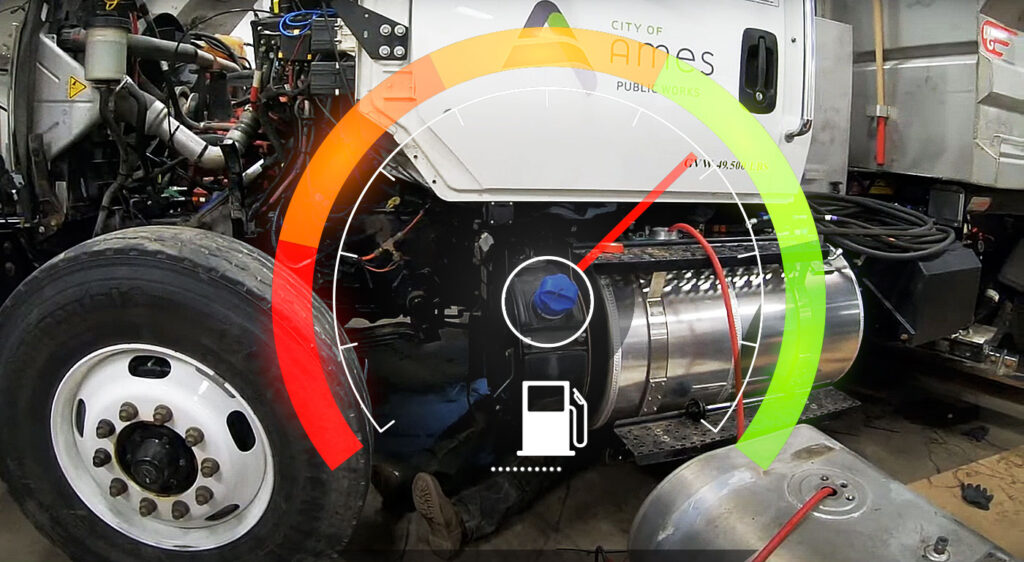

A diesel vehicle can run on B100 year-round with an easy and affordable upgrade. An updated fuel storage system includes a split tank for petroleum diesel in one section and biodiesel in another. Diesel is used on startup to prevent any cold flow issues. The system warms the biodiesel and automatically switches the truck to 100% biodiesel. At shut-off, the truck idles long enough to replace the B100 in the lines with diesel.

What infrastructure changes are required to run on B100?

Biodiesel can be used in the same storage tanks and dispensing infrastructure as ULSD. However, fleets using B100 typically install a dedicated biodiesel tank because they still use petroleum diesel or biodiesel blends. Your supplier can work with you to review existing infrastructure and determine whether any changes are needed.

How does B100 help in reducing emissions?

As you may know, a growing number of cities and states are mandating clean-air standards, and more fleets and their customers are setting sustainability targets of their own. Simply put: We need to do better now — not a few years down the road.

Biodiesel is one of the most effective fuels available for significantly and immediately reducing harmful emissions. Here are the stats for my company’s biodiesel as an example:

- Emits 88% less CO2 than ULSD;

- Emits 85% less CO2 than compressed natural gas (CNG); and

- Emits 65% less CO2 than an electric vehicle on the average U.S. grid.

Does it still perform well?

Yes! Biodiesel can give fleets some serious maintenance and performance advantages. Using B2 (just 2% biodiesel, 98% ULSD) provides more lubricity than required by the ASTM spec for diesel — so imagine how beneficial that lubricity becomes when you jump to B100.

Biodiesel also has a higher Cetane spec than petroleum diesel’s ASTM requirement, so it provides a shorter ignition time. That means more complete combustion, which leads to more efficient engine operation. That cleaner burn also means less soot gets to the DPF, causing fewer regens and less wear.

Will I see a good ROI after investing in this technology?

You bet. The B100 system is affordable and only adds one new component that requires maintenance — a dedicated biodiesel filter — so the maintenance impact is minimal. As mentioned, biodiesel can actually offer improved maintenance attributes, contributing to a lower total cost of ownership.

Also, biodiesel is priced competitively with diesel fuel. Altogether, the initial cost of switching to B100 technology is paid off fairly quickly. Plus, as sustainability plans and regulations spread, running on B100 could make your fleet a much more attractive partner to companies or organizations who need to reduce their environmental impact quickly.

B100: How It Works

- A fuel delivery system with a split tank is installed: one for petroleum diesel and one for biodiesel.

- Diesel is used for startup.

- The system warms the biodiesel and automatically switches the truck to 100% biodiesel when ready.

- At shut-off, the truck idles for a couple minutes while biodiesel is purged from the lines.

Steve Klein is senior manager, marketing at Renewable Energy Group, a biodiesel and renewable diesel producer. He can be reached at [email protected].