Grote Industries has unveiled the latest in a series of products that anticipate and answer the trucking industry’s future lighting and electrical needs: the Grote next generation J 560 Ultra-Box Receptacle.

Grote Industries has unveiled the latest in a series of products that anticipate and answer the trucking industry’s future lighting and electrical needs: the Grote next generation J 560 Ultra-Box Receptacle.

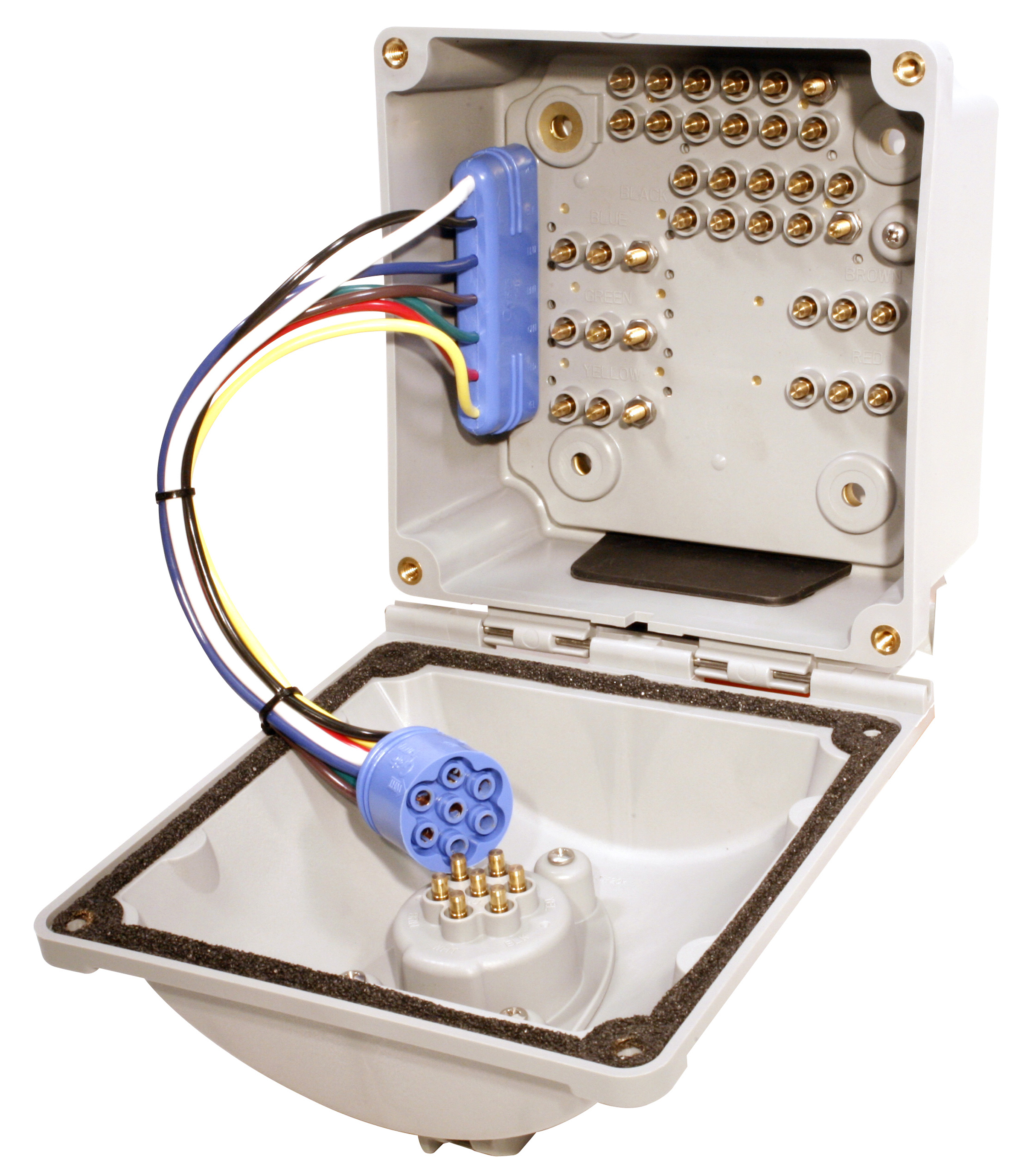

The product solves the current problem of cracked, corroded and crammed truck trailer junction boxes said its maker. With double the standard number of pin connections, a push-on plug function, a durable glass-filled nylon housing, insert-molded pins that seal out moisture and corrosive materials and easily replaceable parts, Grote’s Ultra-Box receptacle is ready for future growth.

"We went right to the source as we designed, engineered and prepared to manufacture our new Ultra-Box receptacle," explained Darren Harmon, group manager for Grote’s core products engineering division. "Then, we put it through a series of brutal, punishing tests to make sure seals locked out moisture and grime. The result is a product that performs."

From molded, threaded brass inserts that ensure the nose box is locked down to a special mounting gasket that protects against moisture, the Ultra-Box receptacle pays attention to performance details, according to Harmon.

Grote sought input from experienced original equipment manufacturers familiar with how fleets and individual drivers are using and abusing their trailer’s nose boxes. Standard nose boxes have become an over-taxed, tangled mess of spliced and wrapped wires from the functions already demanded of them from additional interior dome lights to tire inflation units.

"So we designed and manufactured the Grote Ultra-Box to be not only bigger and more rugged now, but to offer the future wiring capacity needed to handle the demands associated with new items coming on line: such things as additional LED interior dome lights and related switches, new GPS trailer tracking devices, sophisticated monitoring devices and other new electronic trailer features," Harmon explained.

The nose box also accommodates an industry move to run more ground return systems for a cleaner power system, overall.

Bigger both in physical size and capacity, Grote’s nose box features 39 pin connections instead of the industry standard 28. It accepts a variety of manufacturers’ plugs. The main power cord hatch is replaceable, as is the main receptacle. In fact, the main receptacle can be swapped out in as little as 10 minutes versus 45 minutes for the old, standard receptacle.

Despite its larger dimensions, Grote’s Ultra-Box retains the same four-hole footprint, making it easy to retrofit any trailer.

The nose box also was specifically designed to minimize wiring mistakes and make it easier and faster to service on the road, minimizing downtime and maximizing fleet and driver efficiency, according to Grote’s spokesman.

"We thought of everything to meet the industry’s future needs," said Harmon. "This is not a Band-Aid. The Grote Ultra-Box receptacle will take trucking into the years ahead.

"Our Ultra-Box is one more example of Grote Industries’ commitment to consistent, excellent performance from design to engineering to manufacture and on-the-job function," said Dominic Grote, vice president of sales and marketing for Grote Industries.

To learn more about Grote’s Ultra-Box receptacle, visit http://www.grote.com or call 1-800-628-0809.